-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- Galvanized and Stainless Steel Cylindrical Braids

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

PVC Bellows – What Are They, How Do They Work, and What Are They Used For?

In order for the industry to achieve the maximum level of production with the highest efficiency, it is necessary to unify the work criteria and focus them on ensuring the optimal functioning of machines. Machines responsible for a large portion of industrial work consist of many components that need to be properly protected to function correctly and carry out all processes. One of the most desirable protection systems in industrial machines are bellows, which, regardless of the material they are made of, are suitable for protecting machine components. In this post, we will explain everything about bellows made of polyvinyl chloride (PVC), one of the most commonly used materials in the industry.

PVC Bellows - What Are They, How Do They Work, and What Are They Used For?

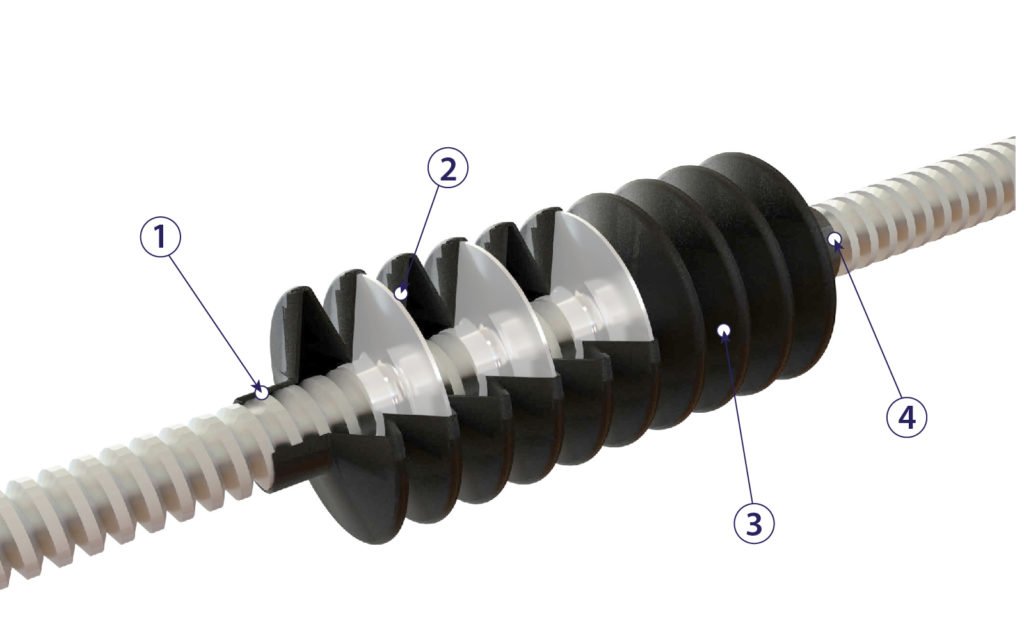

1. Mounting ends

2. Internal guide (if necessary)

3. Rubber

4. Mounting ends

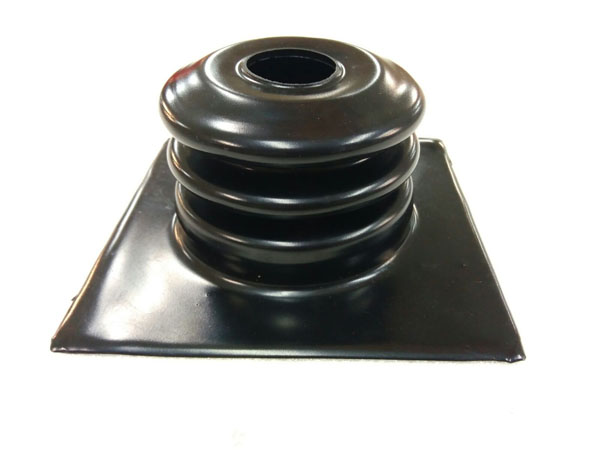

PVC Bellows are a mechanism designed to protect the moving and stationary parts of all types of machines used in industries that conduct large-scale production processes.

The use of PVC bellows guarantees protection of the machine from harmful factors resulting from its operation, which can cause serious damage, including partial or complete shutdown of the equipment.

How do PVC Bellows differ from those made of other materials?

Polyvinyl chloride (PVC) is a product created by the chemical combination of carbon, hydrogen, and chlorine. It ranks third in the global plastic production market.

There are two types of PVC that can be used to make bellows: flexible and rigid. Both are highly resistant to abrasion and chemicals, ensuring safety and efficiency during the production of such devices and their installation on the machine.

PVC bellows differ from others in that the material from which they are made is created by the polymerization of vinyl chloride, which is formed by combining chlorine and ethylene, allowing for the production of a lightweight and chemically neutral plastic.

These types of bellows are very versatile and are also used in systems requiring products designed for long-lasting use; their service life can exceed 15 years.

What Types of Bellows Are Made from PVC?

On the market for protective bellows for industrial machines, you can find a wide range of products varying in shape, size, and, of course, the type of material used to make them.

PVC Bellows can be supplied in different shapes.

PVC bellows come in various forms such as:

• Hexagonal,

• Curtain,

• Rectangular,

• For guides,

• Formed,

• Sewn,

• Self-winding,

In some cases, rigid PVC is also used to reinforce the interior folds of the bellows, providing even better protection.

What Can Be Protected Using PVC Bellows?

PVC Bellows can protect various machine components, such as:

• Guides,

• Sliding tables,

• Lead screws,

• Cylinders,

• Wiring,

• Mechanical elements,

• Robotic arm joints,

• Pneumatic actuators.

They are also used to protect linear guides, lathes, gearboxes, and in small spaces. This effectively prevents machine failures and unexpected stoppages.

What Are the Benefits of Using PVC Bellows?

The key advantages of using PVC bellows are:

- Versatility and excellent value for money.

- Made from a lightweight, durable, and fire-resistant material.

- Resistance to deformation, waterproofing, and high resistance to weather conditions.

- Protection of machine components from coolants, dust, water, oils, acids, hydrocarbons, and hot chips.

- Metal mounting ends for installation in the machine.

- The possibility of mounting in "U" profiles for proper operation.

- Internal reinforcements in the folds, and in some cases, also with sliding guides or anti-abrasive clamps.

- Reduction in machine maintenance costs.

- Extension of equipment service life.

- Optimization of production processes.

Summary

Choosing the right material for a protective bellows for industrial machine components is crucial, as not every material provides the same level of protection. PVC bellows are among the most commonly used in industry and guarantee continuity in production processes. They are resistant, high-quality, and lightweight. They ensure maximum equipment efficiency, as well as an effective and balanced production process that allows for achieving goals and expected results. Available in various shapes and sizes, such as hexagonal, curtain, rectangular, for guides, formed, sewn, and self-winding – made of highly resistant PVC. In addition to providing comprehensive protection for machines against external factors, PVC bellows allow devices to operate in optimal conditions, reduce maintenance costs, and extend their service life. Covers play a very important role in safety, protecting workers from undesirable external factors that can cause bodily injuries, and in extreme cases, lead to disability or death of machine operators.

If you want to effectively protect your machine – PVC bellows are an excellent solution!

Related product

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment