-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

-

Recorders

- Hybrid Recorders - AL3000 Series | CHINO

- Graphic Recorder - KR2000 Series | CHINO

- Ubiquitous Recorders - KR5000 Series | CHINO

- Palm-sized Temperature/Humidity Meters - HN-CH Series | CHINO

- Consumables for Recorders

- 71VR1 - Compact Paperless Recorder | M-SYSTEM

- Graphic Recorder - KR3000 Series | CHINO

- PC Recorders - R1M Series | M-SYSTEM

- PC Recorders - R2M Series | M-SYSTEM

- PC Recorders - RZMS Series | M-SYSTEM

- PC Recorders - RZUS Series | M-SYSTEM

- Go to the subcategory

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- Galvanized and Stainless Steel Cylindrical Braids

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Hoses

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Pulsiv OSMIUM: Transforming AC-DC Power Conversion with Unmatched Efficiency and Versatility

Pulsiv OSMIUM: Revolutionizing AC-DC Power Conversion Efficiency and Scalability

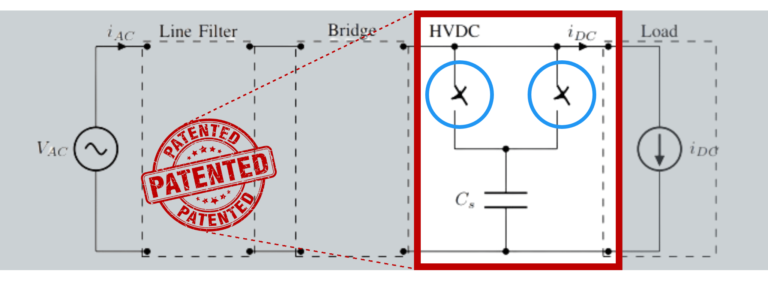

Utilizing patented switching technology, Pulsiv has developed a completely new method for converting alternating current (AC) to direct current (DC) that offers a game-changing combination of benefits in power electronics projects. Our unique technology has expanded conventional flyback topologies to replace costly LLC solutions while achieving an unparalleled performance profile.

Patented Switching Technique

line filter - line filter

Bridge – bridge

Load - load

- AC to DC conversion is achieved by charging/discharging an energy storage capacitor

- Power factor correction no longer requires a PFC inductor

- System losses are significantly reduced at low power to maximize efficiency

- Enables the replacement of LLC technology

- Ability to remove the synchronous rectifier to save additional costs

- Inrush current is completely eliminated

Technological Achievements

| Achievement | Result | Existing Solutions | Notes |

|---|---|---|---|

| Peak Front-End Efficiency | 99.5% | 98% | Reduced losses due to no need for a PFC inductor |

| Average Front-End Efficiency | 97.5% | 95% | Compared to Boost PFC design |

| Average End-to-End Efficiency | 91% | 88% | Based on Pulsiv flyback reference design |

| Low Power Efficiency (2W) | 90% | 70% - 75% | Exceeds Energy Star standard by 20% |

| Single Flyback Switch Design | 180W | 70W – 90W | Up to 100% more power compared to current market solutions |

| Interleaved Flyback | 350W | 200W – 300W | Up to 75% more power compared to current market solutions |

| X-Cap Discharge | Automatic | Resistors / External Controller | No additional external controllers required |

| Inrush Current | None | External solutions | Pulsiv has completely eliminated inrush current |

| Power Supply Component Count | 100 components | 150 components | 95% off-the-shelf components, -33% fewer components |

| Power Factor | 0.96 | up to 0.99 | Achieved without a PFC inductor |

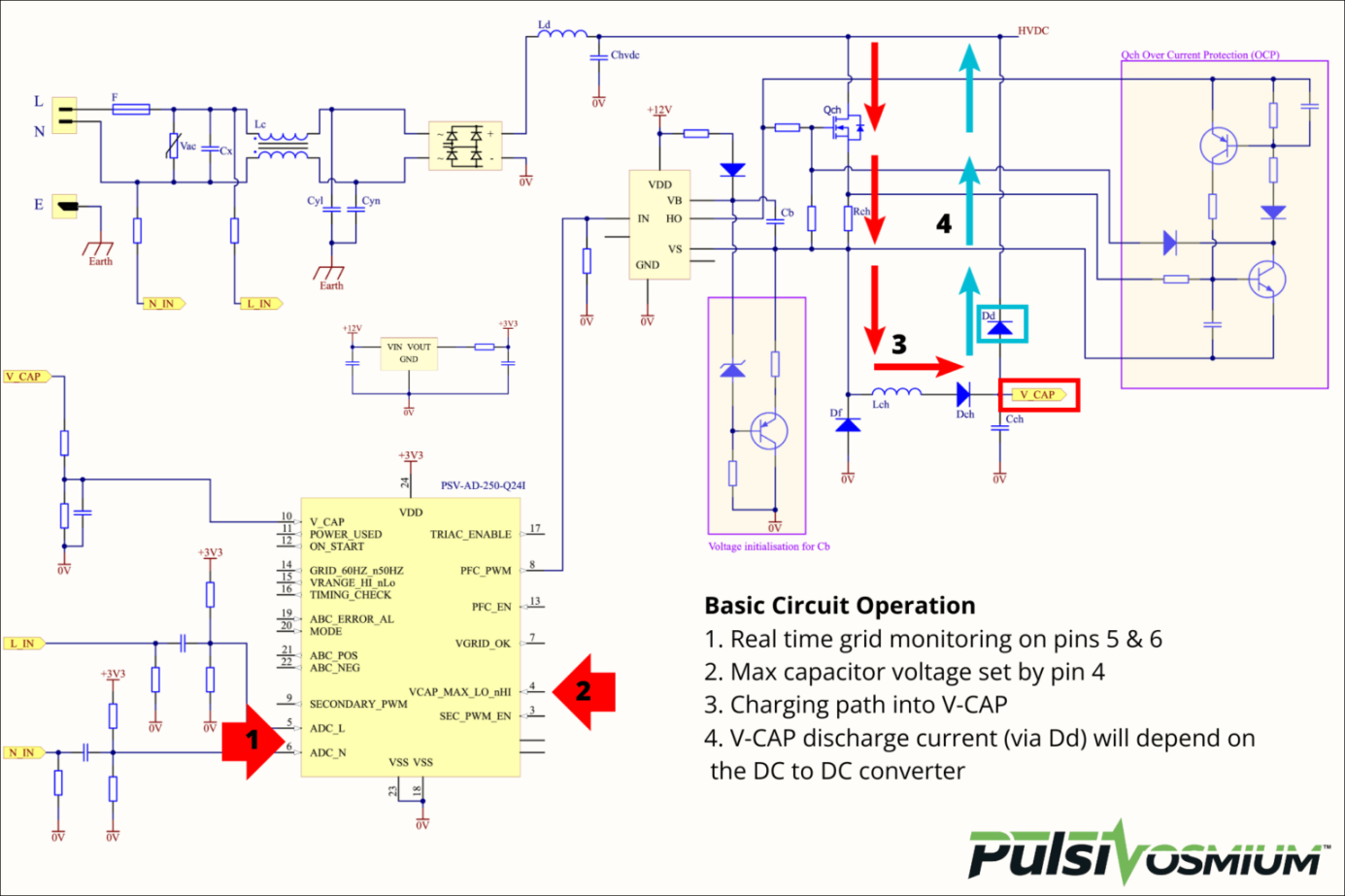

Basic Circuit Functionality

We offer an intelligent microcontroller, programming system for front-end assessment, and a full range of downloadable documents to simplify the design process. Pulsiv OSMIUM provides a scalable platform for engineers to reduce size, improve energy consumption, and optimize costs when designing power supplies for virtually any mains-powered or battery-charging application.

Applications of Pulsiv Technology

Consumer Electronics

Leading electronics brands are continually seeking ways to create a competitive advantage, often leveraging technological innovations as a key differentiator. Pulsiv solutions provide significant improvements in power density, efficiency, and size without increasing costs. We actively collaborate with consumer electronics manufacturers to demonstrate how our technology can achieve their goals, meet stringent industry regulations, and reduce overall energy consumption.

LED Lighting

With changing regulations and record-high energy prices, the LED lighting sector is expected to grow significantly over the next decade. Our technology can be utilized by lighting manufacturers to design more sustainable, cost-effective, and energy-efficient products. As the world's first company to completely eliminate inrush current in LED drivers, large-scale lighting designs become less complex, cheaper, and faster to install.

Industrial Power Supplies

Commercial power supply manufacturers continue to improve power density, efficiency, and reliability across a range of applications, from factory automation to medical devices. Our flexible technology provides a new platform for developing a portfolio of highly efficient, ultra-compact, and cost-effective power supplies. Additional features include expanded flyback technology (up to 350W), automatic x-cap discharge, and complete elimination of inrush current to simplify product design.

Power Adapters

Power adapters are commonly used in household appliances that operate or charge from a wall socket. Regulations worldwide are continually evolving to promote standardization, improve safety, and reduce energy consumption. Pulsiv offers leading technology to meet these challenges, enabling the use of conventional flyback designs to improve power density, efficiency, and size compared to higher-cost alternatives. Our solutions can also be optimized for USB-C adapters, which will become mandatory in Europe following changes to the EU Radio Equipment Directive aimed at reducing electronic waste.

Battery Chargers

Many applications now use batteries as the primary power source. While innovations in battery technology offer the potential for increased capacity and faster charging, high-performance power electronics are needed to unlock their full potential. We enable the use of conventional flyback designs up to 350W with a universal input voltage range to charge the most advanced batteries. Our solutions contribute to improved efficiency, reduced size, and cost optimization in the development of modern battery chargers.

Solar Technology

Solar energy has become a popular choice for generating clean energy, and Pulsiv provides technology that enables customers to access every watt of free energy. Pulsiv HORIZON designs harness previously unused solar energy, efficiently generating high-voltage AC or DC power and can be configured to match the capabilities of panels. Making Pulsiv HORIZON available to a wide ecosystem can enhance overall efficiency, improve solar energy economics, and accelerate the global transition to renewable energy.

Delivering a Unique Combination of Benefits

High efficiency profile from low power to full load

The Pulsiv OSMIUM front-end solution exceeds the Energy Star VI standard by up to 20%. This allows the use of flyback technology at higher power levels, simplifies the design process, and can improve overall energy consumption.

Replacing LLC Designs with Flyback Technology

Conventional LLC designs can now be replaced with more cost-effective flyback solutions combined with Pulsiv OSMIUM technology. Our unique approach can extend the range of efficient flyback designs (single switch 180W and 350W with interleaving and universal input) to reduce losses and improve overall energy consumption.

Enhanced Thermal Performance for Greater Reliability

In Pulsiv OSMIUM design, key components operate at significantly lower temperatures than conventional power supplies. This reduces component failure rates and extends expected lifespan, even with convection cooling.

Eliminated Inrush Current

By regulating the mains flow to the charging capacitor, Pulsiv has become the world's first company to completely eliminate inrush current. For industrial power supply/LED driver manufacturers, system design, installation, and costs have been significantly improved.

Integrated Features

Standard Features Included

X-Cap Discharge - Pulsiv’s microcontroller, when used with a half-active bridge, offers signals to discharge the x-capacitor automatically. Currently, x-cap discharge is only possible by using an external silicon chip adding cost and space, or by using resistors which, while low cost, continuously dissipates heat resulting in a less efficient solution.

AUX Output Control - Signals are provided to produce an auxiliary power source independent from the main power supply. This standard feature can be used without the need for a separate controller, which typically requires additional space, cost, and design time.

Grid Failure Detection - When the grid supply falls below SOV, a signal is provided to give the earliest possible warning so that any necessary action can be taken in downstream systems. This is particularly useful in safety-critical applications or where a controlled shutdown is required.

Power Consumption Indicator - A signal is provided as standard that switches at a frequency directly proportional to the output power. This can be used to indicate or log real-time power consumption without the need for additional components traditionally used to support this feature.

Selectable Max HVDC Output - Providing the ability to select the voltage rating of the storage capacitor allows engineers to optimize the capacitor selection for cost or performance. This flexibility enables engineers to configure the design according to their application's needs by choosing between 160V or 200V capacitors.

Optional Features

Active Bridge Control - Using an active bridge in a switch mode power supply design is a recognized method to improve efficiency and reduce losses compared to a traditional bridge rectifier solution. Signals are provided to manage and support the additional components.

Configurable Hold Up - Hold up provides energy storage for a system to continue operating for a period of time after the input supply is lost or removed. Once engineers have defined the required hold up time, they can configure the necessary components to meet the needs of their application.

For more information on any of these features, please refer to the PSV-AD-xx datasheets or contact us directly.

Scalable Platform

The Pulsiv OSMIUM microcontroller does not directly determine the output power. Changing just 3 key components (inductor, MOSFET transistor, and capacitor) ensures it can be used across the entire product family.

Smooth System Integration

Circuit configurations combine the Pulsiv OSMIUM microcontroller and various auxiliary components to provide a complete AC-DC front-end design. Full reference designs combine the front-end circuit configuration with a pre-selected DC-DC converter to provide a comprehensive solution that meets relevant EMC/FCC regulations.

Related product

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment