Category

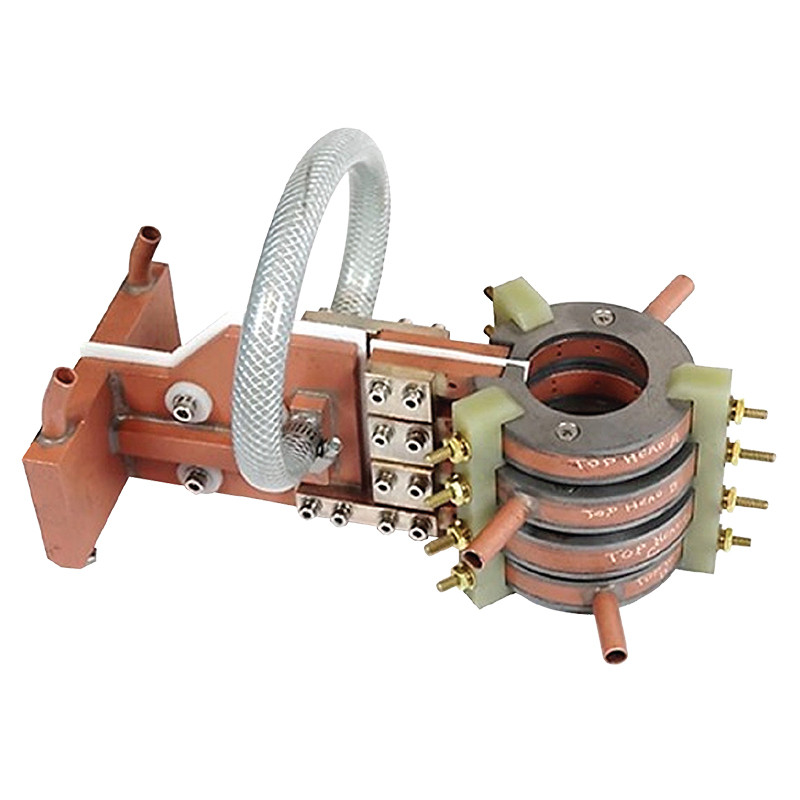

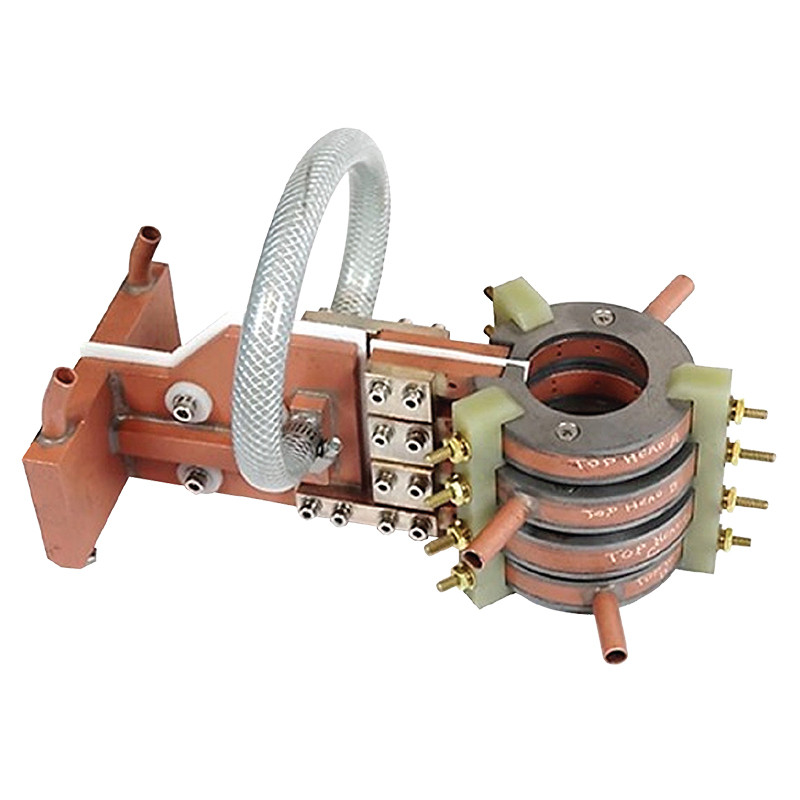

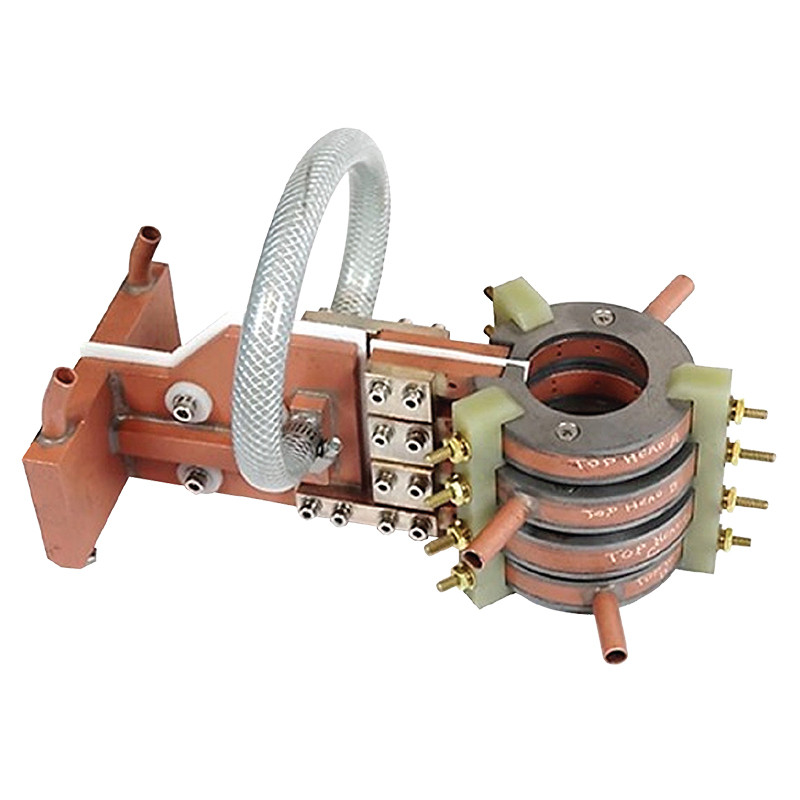

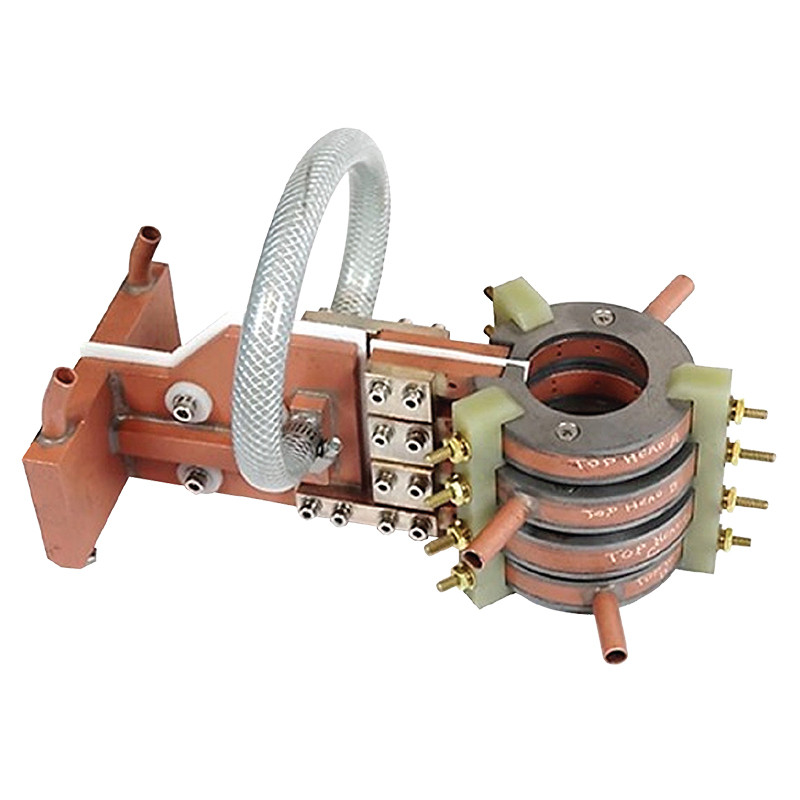

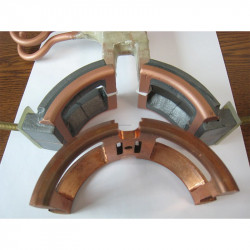

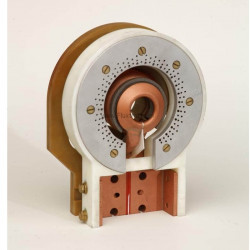

Photos are for informational purposes only. View product specification

please use latin characters

Fluxtrol materials are soft magnetic composites made of magnetic powdered metals and dielectric binders by compacting at high pressures with subsequent thermal treatment. They are used for magnetic flux control (concentrating, shielding or modifying), essentially capturing the alternating magnetic field and re-directing or focusing it to the desired area of the workpiece (or part). These materials are characterized as having low electrical conductivity, high magnetic permeability and low magnetic losses.

Magnetic Flux Control is a generic term for modification of induction coil magnetic flux by means of installation of magnetic templates (magnetic flux controllers). Magnetic controllers may significantly change magnetic field pattern and coil parameters; their application must be considered as a part of the whole induction system design.How Does Fluxtrol Concentrator Work?

Magnetic flux always flows around an inductor (or coil) in closed loop path. Fluxtrol soft magnetic materials provide an easier way for the magnetic field to travel than traveling in air, thus increasing field intensity or localizing the magnetic field on the electrically conductive body surface (i.e., part or workpiece) in close proximity. Fluxtrol flux concentrators strongly reduce the back-path magnetic resistance, due to the high permeability of our soft magnetic material and concentrate the induced power in the critical area of the workpiece. When applied to an inductor (or coil), Fluxtrol flux concentrators provide increased heating in desirable zones and reduce heating in undesirable zones. Magnetic field distribution and heat patterns are controllable, process efficiencies increase, cycle times decrease and energy savings result from using Fluxtrol flux concentrators. In many cases, the application of our proprietary soft magnetic materials, make a seemingly impossible task a manageable

Fluxtrol Types:

- Fluxtrol A

Ideal for low and medium frequency applications (1-50kHz). Highest magnetic permeability in the Fluxtrol family of soft magnetic materials. Material has excellent mechanical strength, machinability and thermal conductivity.

- Fluxtrol 50

Excellent performance over a wide range of frequencies (10–1000kHz). Good magnetic permeability for low and medium frequency applications, yet offers the highest permeability in the Fluxtrol family of soft magnetic materials in high frequency applications. Material has excellent mechanical strength, machinability and thermal conductivity.

- Ferrotron 559H

Proven flux concentrator performance with the highest electrical resistivity in the Fluxtrol family of soft magnetic materials. Almost constant magnetic permeability over a range of magnetic flux densities and frequencies (10-3000 kHz). Material has excellent mechanical strength, machinability and thermal conductivity.

Standard dimensions

| Small sizes / rollers | |

| Dimension in inches | metric |

| 0.37 Dia x 2.00 | (9.4 Ø x 50.8) |

| 0.50 Dia x 2.00 | (12.7 Ø x 50.8) |

| 0.50 Dia x 2.50 | (12.7 Ø x 63.5) |

| 0.67 Dia x 2.00 | (17.0 Ø x 50.8) |

| 0.75 Dia x 2.00 | (19.0 Ø x 50.8) |

| 1.00 Dia x 2.00 | (25.4 Ø x 50.8) |

| 1.00 Dia x 3.00 | (25.4 Ø x 76.2) |

| 1.25 Dia x 2.00 | (31.7 Ø x 76.2) |

| 1.25 Dia x 3.00 | (31.7 Ø x 76.2) |

| 1.50 Dia x 2.00 | (38.1 Ø x 50.8) |

| 1.50 Dia x 3.00 | (38.1 Ø x 76.2) |

| 1.75 Dia x 2.00 | (44.5 Ø x 50.8) |

| 1.75 Dia x 3.00 | (44.5 Ø x 76.2) |

| 2.00 Dia x 2.00 | (50.8 Ø x 50.8) |

| 2.00 Dia x 3.00 | (50.8 Ø x 76.2) |

| 2.30 Dia x 2.00 | (58.4 Ø x 50.8) |

| 2.30 Dia x 3.00 | (58.4 Ø x 76.2) |

| 2.30 Dia x 5.12 | (58.4 Ø x 130) |

| 2.50 Dia x 2.00 | (63.5 Ø x 50.8) |

| 2.50 Dia x 2.50 | (63.5 Ø x 63.5) |

| 2.50 Dia x 3.00 | (63.5 Ø x 76.2) |

| 2.76 Dia x 2.00 | (70.1 Ø x 50.8) |

| 2.76 Dia x 2.50 | (70.1 Ø x 63.5) |

| 2.76 Dia x 3.00 | (70.1 Ø x 76.2) |

| 3.00 Dia x 1.00 | (76.2 Ø x 25.4) |

| 3.00 Dia x 2.00 | (76.2 Ø x 50.8) |

| 3.00 Dia x 2.50 | (76.2 Ø x 63.5) |

| 3.00 Dia x 3.00 | (76.2 Ø x 76.2) |

| 3.50 Dia x 1.00 | (89.0 Ø x 25.4) |

| 3.50 Dia x 2.00 | (89.0 Ø x 50.8) |

| 3.50 Dia x 2.50 | (89.0 Ø x 63.5) |

| Big sizes / rollers | |

| Dimension in inches | metric |

| 4.00 Dia x 0.75 | (101.5 Ø x 19.0) |

| 4.00 Dia x 1.00 | (101.5 Ø x 25.4) |

| 4.00 Dia x 2.00 | (101.5 Ø x 50.8) |

| 4.50 Dia x 1.00 | (114.3 Ø x 25.4) |

| 4.50 Dia x 2.00 | (114.3 Ø x 50.8) |

| 5.00 Dia x 0.25 | (127.0 Ø x 6.3) |

| 5.00 Dia x 0.75 | (127.0 Ø x 19.0) |

| 5.00 Dia x 1.00 | (127.0 Ø x 25.4) |

| 5.00 Dia x 2.00 | (127.0 Ø x 50.8) |

| 5.50 Dia x 1.00 | (140.0 Ø x 25.4) |

| 5.50 Dia x 1.25 | (140.0 Ø x 31.7) |

| 5.50 Dia x 2.00 | (140.0 Ø x 50.8) |

| 6.00 Dia x 0.25 | (152.4 Ø x 6.3) |

| 6.00 Dia x 0.75 | (152.4 Ø x 19.0) |

| 6.00 Dia x 1.00 | (152.4 Ø x 25.4) |

| 6.00 Dia x 2.00 | (152.4 Ø x 50.8) |

| 6.50 Dia x 0.25 | (165.1 Ø x 6.3) |

| 6.50 Dia x 0.75 | (165.1 Ø x 19.0) |

| 6.50 Dia x 1.00 | (165.1 Ø x 25.4) |

| 6.50 Dia x 1.25 | (165.1 Ø x 31.7) |

| 6.50 Dia x 1.50 | (165.1 Ø x 38. 1) |

| 6.50 Dia x 1.75 | (165.1 Ø x 44.5) |

| 6.50 Dia x 2.00 | (165.1 Ø x 50.8) |

| 8.00 Dia x 0.75 | (203.2 Ø x 19.0) |

| 8.00 Dia x 1.00 | (203.2 Ø x 25.4) |

| 8.00 Dia x 1.50 | (203.2 Ø x 38. 1) |

| 8.00 Dia x 1.75 | (203.2 Ø x 44.5) |

| 8.00 Dia x 2.00 | (203.2 Ø x 50.8) |

| 9.00 Dia x 0.25 | (228.6 Ø x 6.3) |

| 9.00 Dia x 1.00 | (228.6 Ø x 25.4) |

| 9.00 Dia x 1.75 | (228.6 Ø x 44.5) |

| Small blocks | |

| Dimension in inches | metric |

| 0.25 x 1.00 x 4.00 | (6.3 x 25.4 x 101.5) |

| 0.25 x 1.50 x 4.00 | (6.3 x 38.1 x 101.5) |

| 0.25 x 3.00 x 4.00 | (6.3 x 76.2 x 101.5) |

| 0.50 x 0.50 x 4.00 | (12.7 x 12.7 x 101.5) |

| 0.50 x 0.75 x 4.00 | (12.7 x 19 x 101.5) |

| 0.50 x 1.00 x 4.00 | (12.7 x 25.4 x 101.5) |

| 0.50 x 1.50 x 4.00 | (12.7 x 38.1 x 101.5) |

| 0.50 x 2.00 x 4.00 | (12.7 x 50.8 x 101.5) |

| 0.63 x 0.63 x 4.00 | (16 x 16 x 101.5) |

| 0.63 x 0.75 x 4.00 | (16 x 19 x 101.5) |

| 0.63 x 1.00 x 4.00 | (16 x 25.4 x 101.5) |

| 0.63 x 2.00 x 4.00 | (16 x 50.8 x 101.5) |

| 0.75 x 0.75 x 4.00 | (19 x 19 x 101.5) |

| 0.75 x 1.00 x 4.00 | (19 x 25.4 x 101.5) |

| 0.75 x 1.50 x 4.00 | (19 x 38.1 x 101.5) |

| 0.75 x 2.00 x 4.00 | (19 x 50.8 x 101.5) |

| 1.00 x 1.00 x 2.00 | (25.4 x 25.4 x 50.8) |

| 1.00 x 1.00 x 3.00 | (25.4 x 25.4 x 76.2) |

| 1.00 x 1.00 x 4.00 | (25.4 x 25.4 x 101.5) |

| 1.00 x 1.25 x 4.00 | (25.4 x 31.7 x 101.5) |

| 1.00 x 1.50 x 3.00 | (25.4 x 38.1 x 76.2) |

| 1.00 x 1.50 x 4.00 | (25.4 x 38.1 x 101.5) |

| 1.00 x 2.00 x 4.00 | (25.4 x 50.8 x 101.5) |

| Big blocks | |

| Dimension in inches | metric |

| 0.25 x 4.25 x 6.50 | (6.3 x 107.9 x 165) |

| 0.38 x 4.25 x 6.50 | (9.6 x 107.9 x 165) |

| 0.50 x 4.25 x 6.50 | (12.7 x 107.9 x 165) |

| 0.63 x 4.25 x 6.50 | (16 x 107.9 x 165) |

| 0.75 x 4.25 x 6.50 | (19 x 107.9 x 165) |

| 1.00 x 4.25 x 6.50 | (25.4 x 107.9 x 165) |

| 0.25 x 3.12 x 8.75 | (6.3 x 79.2 x 222.2) |

| 0.38 x 3.12 x 8.75 | (9.6 x 79.2 x 222.2) |

| 0.50 x 3.12 x 8.75 | (12.7 x 79.2 x 222.2) |

| 0.63 x 3.12 x 8.75 | (16 x 79.2 x 222.2) |

| 0.75 x 3.12 x 8.75 | (19 x 79.2 x 222.2) |

| 1.00 x 3.12 x 8.75 | (25.4 x 79.2 x 222.2) |

| 0.25 x 6.50 x 8.75 | (6.3 x 165 x 222.2) |

| 0.38 x 6.50 x 8.75 | (9.6 x 165 x 222.2) |

| 0.50 x 6.50 x 8.75 | (12.7 x 165 x 222.2) |

| 0.63 x 6.50 x 8.75 | (16.0 x 165 x 222.2) |

| 0.75 x 6.50 x 8.75 | (19.0 x 165 x 222.2) |

| 1.00 x 6.50 x 8.75 | (25.4 x 165 x 222.2) |

Are you interested in this product? Do you need additional information or individual pricing?

Fluxtrol materials are soft magnetic composites made of magnetic powdered metals and dielectric binders by compacting at high pressures with subsequent thermal treatment. They are used for magnetic flux control (concentrating, shielding or modifying), essentially capturing the alternating magnetic field and re-directing or focusing it to the desired area of the workpiece (or part). These materials are characterized as having low electrical conductivity, high magnetic permeability and low magnetic losses.

Magnetic Flux Control is a generic term for modification of induction coil magnetic flux by means of installation of magnetic templates (magnetic flux controllers). Magnetic controllers may significantly change magnetic field pattern and coil parameters; their application must be considered as a part of the whole induction system design.How Does Fluxtrol Concentrator Work?

Magnetic flux always flows around an inductor (or coil) in closed loop path. Fluxtrol soft magnetic materials provide an easier way for the magnetic field to travel than traveling in air, thus increasing field intensity or localizing the magnetic field on the electrically conductive body surface (i.e., part or workpiece) in close proximity. Fluxtrol flux concentrators strongly reduce the back-path magnetic resistance, due to the high permeability of our soft magnetic material and concentrate the induced power in the critical area of the workpiece. When applied to an inductor (or coil), Fluxtrol flux concentrators provide increased heating in desirable zones and reduce heating in undesirable zones. Magnetic field distribution and heat patterns are controllable, process efficiencies increase, cycle times decrease and energy savings result from using Fluxtrol flux concentrators. In many cases, the application of our proprietary soft magnetic materials, make a seemingly impossible task a manageable

Fluxtrol Types:

- Fluxtrol A

Ideal for low and medium frequency applications (1-50kHz). Highest magnetic permeability in the Fluxtrol family of soft magnetic materials. Material has excellent mechanical strength, machinability and thermal conductivity.

- Fluxtrol 50

Excellent performance over a wide range of frequencies (10–1000kHz). Good magnetic permeability for low and medium frequency applications, yet offers the highest permeability in the Fluxtrol family of soft magnetic materials in high frequency applications. Material has excellent mechanical strength, machinability and thermal conductivity.

- Ferrotron 559H

Proven flux concentrator performance with the highest electrical resistivity in the Fluxtrol family of soft magnetic materials. Almost constant magnetic permeability over a range of magnetic flux densities and frequencies (10-3000 kHz). Material has excellent mechanical strength, machinability and thermal conductivity.

Standard dimensions

| Small sizes / rollers | |

| Dimension in inches | metric |

| 0.37 Dia x 2.00 | (9.4 Ø x 50.8) |

| 0.50 Dia x 2.00 | (12.7 Ø x 50.8) |

| 0.50 Dia x 2.50 | (12.7 Ø x 63.5) |

| 0.67 Dia x 2.00 | (17.0 Ø x 50.8) |

| 0.75 Dia x 2.00 | (19.0 Ø x 50.8) |

| 1.00 Dia x 2.00 | (25.4 Ø x 50.8) |

| 1.00 Dia x 3.00 | (25.4 Ø x 76.2) |

| 1.25 Dia x 2.00 | (31.7 Ø x 76.2) |

| 1.25 Dia x 3.00 | (31.7 Ø x 76.2) |

| 1.50 Dia x 2.00 | (38.1 Ø x 50.8) |

| 1.50 Dia x 3.00 | (38.1 Ø x 76.2) |

| 1.75 Dia x 2.00 | (44.5 Ø x 50.8) |

| 1.75 Dia x 3.00 | (44.5 Ø x 76.2) |

| 2.00 Dia x 2.00 | (50.8 Ø x 50.8) |

| 2.00 Dia x 3.00 | (50.8 Ø x 76.2) |

| 2.30 Dia x 2.00 | (58.4 Ø x 50.8) |

| 2.30 Dia x 3.00 | (58.4 Ø x 76.2) |

| 2.30 Dia x 5.12 | (58.4 Ø x 130) |

| 2.50 Dia x 2.00 | (63.5 Ø x 50.8) |

| 2.50 Dia x 2.50 | (63.5 Ø x 63.5) |

| 2.50 Dia x 3.00 | (63.5 Ø x 76.2) |

| 2.76 Dia x 2.00 | (70.1 Ø x 50.8) |

| 2.76 Dia x 2.50 | (70.1 Ø x 63.5) |

| 2.76 Dia x 3.00 | (70.1 Ø x 76.2) |

| 3.00 Dia x 1.00 | (76.2 Ø x 25.4) |

| 3.00 Dia x 2.00 | (76.2 Ø x 50.8) |

| 3.00 Dia x 2.50 | (76.2 Ø x 63.5) |

| 3.00 Dia x 3.00 | (76.2 Ø x 76.2) |

| 3.50 Dia x 1.00 | (89.0 Ø x 25.4) |

| 3.50 Dia x 2.00 | (89.0 Ø x 50.8) |

| 3.50 Dia x 2.50 | (89.0 Ø x 63.5) |

| Big sizes / rollers | |

| Dimension in inches | metric |

| 4.00 Dia x 0.75 | (101.5 Ø x 19.0) |

| 4.00 Dia x 1.00 | (101.5 Ø x 25.4) |

| 4.00 Dia x 2.00 | (101.5 Ø x 50.8) |

| 4.50 Dia x 1.00 | (114.3 Ø x 25.4) |

| 4.50 Dia x 2.00 | (114.3 Ø x 50.8) |

| 5.00 Dia x 0.25 | (127.0 Ø x 6.3) |

| 5.00 Dia x 0.75 | (127.0 Ø x 19.0) |

| 5.00 Dia x 1.00 | (127.0 Ø x 25.4) |

| 5.00 Dia x 2.00 | (127.0 Ø x 50.8) |

| 5.50 Dia x 1.00 | (140.0 Ø x 25.4) |

| 5.50 Dia x 1.25 | (140.0 Ø x 31.7) |

| 5.50 Dia x 2.00 | (140.0 Ø x 50.8) |

| 6.00 Dia x 0.25 | (152.4 Ø x 6.3) |

| 6.00 Dia x 0.75 | (152.4 Ø x 19.0) |

| 6.00 Dia x 1.00 | (152.4 Ø x 25.4) |

| 6.00 Dia x 2.00 | (152.4 Ø x 50.8) |

| 6.50 Dia x 0.25 | (165.1 Ø x 6.3) |

| 6.50 Dia x 0.75 | (165.1 Ø x 19.0) |

| 6.50 Dia x 1.00 | (165.1 Ø x 25.4) |

| 6.50 Dia x 1.25 | (165.1 Ø x 31.7) |

| 6.50 Dia x 1.50 | (165.1 Ø x 38. 1) |

| 6.50 Dia x 1.75 | (165.1 Ø x 44.5) |

| 6.50 Dia x 2.00 | (165.1 Ø x 50.8) |

| 8.00 Dia x 0.75 | (203.2 Ø x 19.0) |

| 8.00 Dia x 1.00 | (203.2 Ø x 25.4) |

| 8.00 Dia x 1.50 | (203.2 Ø x 38. 1) |

| 8.00 Dia x 1.75 | (203.2 Ø x 44.5) |

| 8.00 Dia x 2.00 | (203.2 Ø x 50.8) |

| 9.00 Dia x 0.25 | (228.6 Ø x 6.3) |

| 9.00 Dia x 1.00 | (228.6 Ø x 25.4) |

| 9.00 Dia x 1.75 | (228.6 Ø x 44.5) |

| Small blocks | |

| Dimension in inches | metric |

| 0.25 x 1.00 x 4.00 | (6.3 x 25.4 x 101.5) |

| 0.25 x 1.50 x 4.00 | (6.3 x 38.1 x 101.5) |

| 0.25 x 3.00 x 4.00 | (6.3 x 76.2 x 101.5) |

| 0.50 x 0.50 x 4.00 | (12.7 x 12.7 x 101.5) |

| 0.50 x 0.75 x 4.00 | (12.7 x 19 x 101.5) |

| 0.50 x 1.00 x 4.00 | (12.7 x 25.4 x 101.5) |

| 0.50 x 1.50 x 4.00 | (12.7 x 38.1 x 101.5) |

| 0.50 x 2.00 x 4.00 | (12.7 x 50.8 x 101.5) |

| 0.63 x 0.63 x 4.00 | (16 x 16 x 101.5) |

| 0.63 x 0.75 x 4.00 | (16 x 19 x 101.5) |

| 0.63 x 1.00 x 4.00 | (16 x 25.4 x 101.5) |

| 0.63 x 2.00 x 4.00 | (16 x 50.8 x 101.5) |

| 0.75 x 0.75 x 4.00 | (19 x 19 x 101.5) |

| 0.75 x 1.00 x 4.00 | (19 x 25.4 x 101.5) |

| 0.75 x 1.50 x 4.00 | (19 x 38.1 x 101.5) |

| 0.75 x 2.00 x 4.00 | (19 x 50.8 x 101.5) |

| 1.00 x 1.00 x 2.00 | (25.4 x 25.4 x 50.8) |

| 1.00 x 1.00 x 3.00 | (25.4 x 25.4 x 76.2) |

| 1.00 x 1.00 x 4.00 | (25.4 x 25.4 x 101.5) |

| 1.00 x 1.25 x 4.00 | (25.4 x 31.7 x 101.5) |

| 1.00 x 1.50 x 3.00 | (25.4 x 38.1 x 76.2) |

| 1.00 x 1.50 x 4.00 | (25.4 x 38.1 x 101.5) |

| 1.00 x 2.00 x 4.00 | (25.4 x 50.8 x 101.5) |

| Big blocks | |

| Dimension in inches | metric |

| 0.25 x 4.25 x 6.50 | (6.3 x 107.9 x 165) |

| 0.38 x 4.25 x 6.50 | (9.6 x 107.9 x 165) |

| 0.50 x 4.25 x 6.50 | (12.7 x 107.9 x 165) |

| 0.63 x 4.25 x 6.50 | (16 x 107.9 x 165) |

| 0.75 x 4.25 x 6.50 | (19 x 107.9 x 165) |

| 1.00 x 4.25 x 6.50 | (25.4 x 107.9 x 165) |

| 0.25 x 3.12 x 8.75 | (6.3 x 79.2 x 222.2) |

| 0.38 x 3.12 x 8.75 | (9.6 x 79.2 x 222.2) |

| 0.50 x 3.12 x 8.75 | (12.7 x 79.2 x 222.2) |

| 0.63 x 3.12 x 8.75 | (16 x 79.2 x 222.2) |

| 0.75 x 3.12 x 8.75 | (19 x 79.2 x 222.2) |

| 1.00 x 3.12 x 8.75 | (25.4 x 79.2 x 222.2) |

| 0.25 x 6.50 x 8.75 | (6.3 x 165 x 222.2) |

| 0.38 x 6.50 x 8.75 | (9.6 x 165 x 222.2) |

| 0.50 x 6.50 x 8.75 | (12.7 x 165 x 222.2) |

| 0.63 x 6.50 x 8.75 | (16.0 x 165 x 222.2) |

| 0.75 x 6.50 x 8.75 | (19.0 x 165 x 222.2) |

| 1.00 x 6.50 x 8.75 | (25.4 x 165 x 222.2) |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent