Category

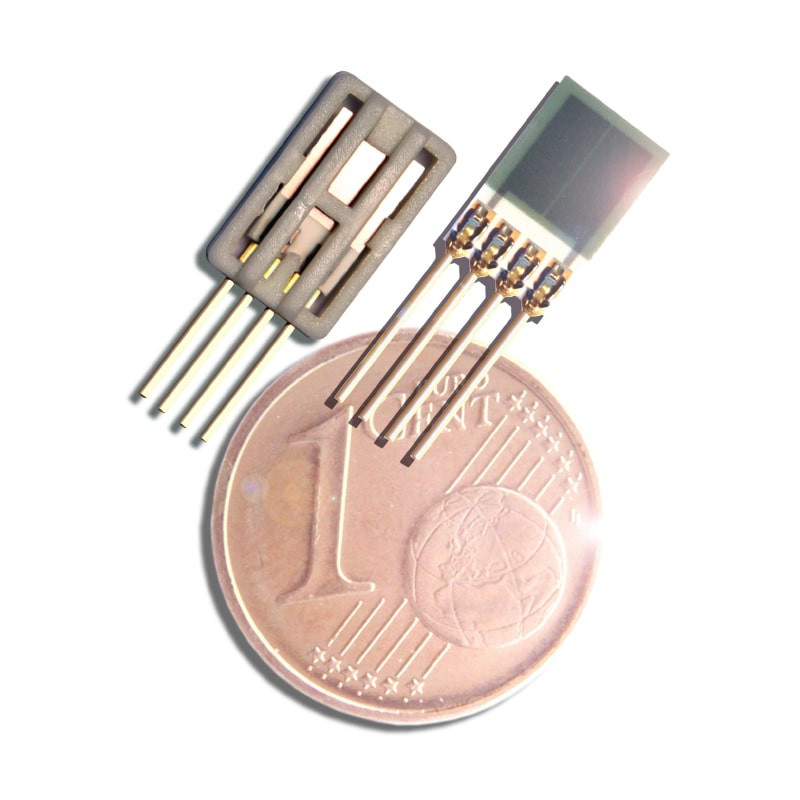

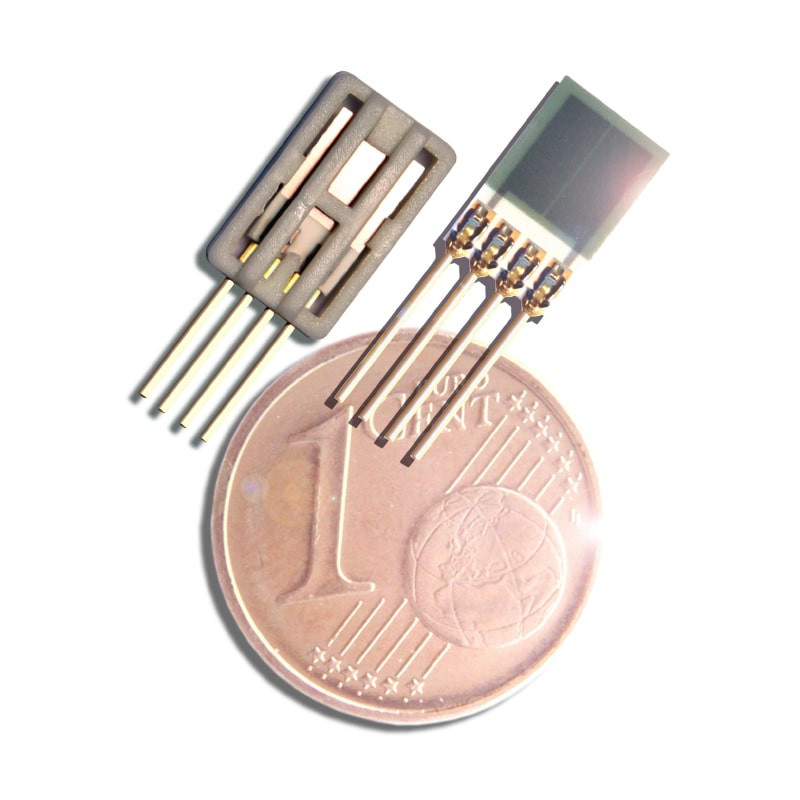

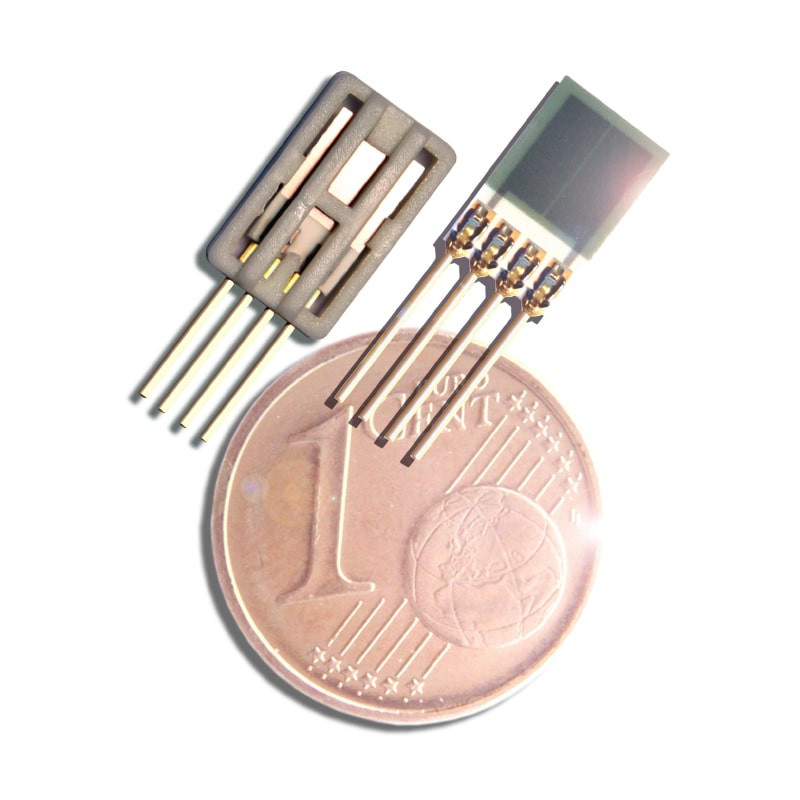

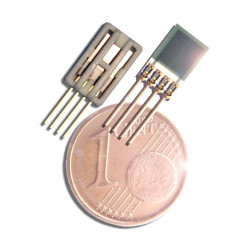

Photos are for informational purposes only. View product specification

please use latin characters

Technical Data: Technical Data: |

|

| Relative Humidity | |

| - measuring range | 0 ... 100 % rh |

| - resolution | 0,5 %rh |

| - accuracy | ±2 %rh 05„.35°C 25...85 %rh) |

| ±3 %rh (15...35°C, 5...25 %rh and 85...95 %rh) | |

| - Additional error | ±0,1 % rh/K @t35°C |

| Temperature | |

| - measuring ranges | see table |

| - resolution | 0.1°C |

| -accuracy | 0.5 K @ 25°C ±1 digit |

| digit(see diagram) | |

| General: | |

| - operating voltage | 5...30 V DC |

| - output signal: | |

| calHT01/1, calHT01/2 | 2 x 0...1 V (przy RL 3 1 MΩ) |

| calHT 06/1, calHT 06/2 | digit (compatible with I2C) |

| - storage temperature | - 65 ... 150°C |

| - working temperature | - 40 ... 85°C |

| - power consumption | < 1 mA |

| Type | Measuring range [°C] |

Labelling |

| calHT01-0100(.R) | 0...100 | Green |

| calHT01-3070(.R) | -30...70 | Black |

| calHT01-2080(.R) | -20..80 | Red |

| calHT01-4060(.R) | -40...60 | Yellow |

| calHT06-4085(.R) | -40...85 | White |

|

|

| Temperature accuracy of calHT 01 and calHT 06 series | Temperature accuracy of calHT 01 and calHT 06 series |

| S | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | A | 0 | 0 | 0 | 0 | C 4 |

C 3 |

C 2 |

C 1 |

A | P |

| R/W | |||||||||||||||||||

Microcontroller requests data byte according control command and reads out

| S | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | A | D 7 |

D 6 |

D 5 |

D 4 |

D 3 |

D 2 |

D 1 |

D 0 |

N A |

P |

| S Start |

R/W

|

||||||||

| P Stop | |||||||||

| A Acknowledge | from sensor | ||||||||

| N/A No Acknowledge | |||||||||

| C 4 |

C 3 |

C 2 |

C 1 |

|

|---|---|---|---|---|

| 0 | 0 | 0 | 0 | Read-Out Humidity |

| 0 | 0 | 1 | 0 | Read-Out Temperature Byte 1 |

| 0 | 0 | 1 | 1 | Read-Out Temperature Byte 2 |

| D 7 |

D 6 |

D |

D 4 |

D 3 |

D 2 |

D 1 |

D 0 |

|

|---|---|---|---|---|---|---|---|---|

| 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | Humidity |

| 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | Temperature Byte 1 |

| X | X | X | X | 0/1 | 0/1 | 0/1 | 0/1 | Temperature Byte 2 |

| Symbol | Parameter | min | max | jednostka |

|---|---|---|---|---|

| tBUF | idle period between BUS actions | 4,7 | μs | |

| tD:SU | data set-up time | 250 | ns | |

| tD:HD | data hold time | 50 | ns | |

| tST:HD | start hold time | 4 | μs | |

| tST:SU | start set-up time | 4,7 | μs | |

| tSCL:L | SCL„low" time | 4,7 | μs | |

| tSCL:H | SCL „high" time | 4 | μs | |

| fSCL | SCL frequency | 100 | kHz | |

| t r | SDA, SCL LOW/HIGH time | 1 | μs | |

| tf | SDA, SCL HIGH/LOW time | 0,3 | μs | |

| tSTO:SU | stop set-up time | 4 | μs | |

| tSP | pulse width of spikes to be suppressed by input filter | 100 | ns | |

| CL | capacitive load SDA, SCL BUS (internal pull-up 120 kW) | 10 | pF | |

| tMUPD | update for measurement values | 40 | ms | |

| tSMPL | sampling period DA converter | 2 | 6 | ms |

Instrukcja użytkowania

Nigdy nie wolno dotykać aktywnej części bardzo czułego czujnika. Należy używać bardzo niskiego napięcia podczas lutowania elementu (temperatura lutowania 240°C, czas lutowania 2 sekundy). Należy oczyścić element pomiarowy delikatnie zdmuchując wszelkie pozostałości z montażu, można również przepłukać element w wodzie destylowanej. Nie wpływa to na charakterystykę czujnika, jednak dokładne pomiary mogą być dokonywane dopiero po całkowitym wysuszeniu elementu. Dotyczy to również sytuacji w której powstanie na elemencie rosa.

| Typ | FE 09/1, FE 09.R/1 FE 09/2, FE09.R/2 |

FE 09/4 FE 09.R/4 |

|---|---|---|

| Zakres działania | 0...100%rh | 0...100%rh |

| Temperatura działania FE09/X | -60...200°C | -60...200°C |

| Temperatura działania FE09.R/X | -40...110°C | -40...110°C |

| Pojemność podstawowa | 135±10pF | 115±15pF |

| Zmiana pojemności | 0,3±0,05pF/%rh | 0,27±0,08pF/%rh |

| Dopuszczalne napięcie | maks. 3V bez DC | maks. 3V bez DC |

| Częstotliwość pomiarowa | 5...200kHz | 5...200kHz |

| Współczynnik strat | <0,03 (przy 10kHz) | <0,03 (przy 50kHz) |

| Czas reakcji (T90) | 10s | 10s |

| Histereza (MR 5...95%rh) | <1,5%rh | <1,5%rh |

| Liniowość (MR 5...95%rh) | <1,5%rh | <1,5%rh |

| Stabilność długoterminowa | <1%rh/a | <1%rh/a |

| Substancja robocza | stężenie |

|---|---|

| NH3 (tylko na krótki czas) | 100 ppm (2 x MAK) |

| N2S | 20 ppm (2 x MAK) |

| SO2 | 3,7 ppm (10 x MAK) |

| No2 | 1,0 ppm (10 x MAK) |

| O2 | 0,6 ppm (10 x MAK) |

| Cl2 | brak wpływu |

Poniższy algorytm może być użyty do wyliczenia zależności temperaturowej elementu pomiarowego.

K = [A+a(T - 25)] Σ bi . T i

K= wartość skorygowana

A= sygnał wyjściowy (0...100%)

T= temperatura(ºC)

bi= 6*10-4

a= 0,04 (dla T≥25ºC)

a= 0 ( dla T<25ºC)

b0= 0,98125

b2= 6*10-6

Are you interested in this product? Do you need additional information or individual pricing?

Technical Data: Technical Data: |

|

| Relative Humidity | |

| - measuring range | 0 ... 100 % rh |

| - resolution | 0,5 %rh |

| - accuracy | ±2 %rh 05„.35°C 25...85 %rh) |

| ±3 %rh (15...35°C, 5...25 %rh and 85...95 %rh) | |

| - Additional error | ±0,1 % rh/K @t35°C |

| Temperature | |

| - measuring ranges | see table |

| - resolution | 0.1°C |

| -accuracy | 0.5 K @ 25°C ±1 digit |

| digit(see diagram) | |

| General: | |

| - operating voltage | 5...30 V DC |

| - output signal: | |

| calHT01/1, calHT01/2 | 2 x 0...1 V (przy RL 3 1 MΩ) |

| calHT 06/1, calHT 06/2 | digit (compatible with I2C) |

| - storage temperature | - 65 ... 150°C |

| - working temperature | - 40 ... 85°C |

| - power consumption | < 1 mA |

| Type | Measuring range [°C] |

Labelling |

| calHT01-0100(.R) | 0...100 | Green |

| calHT01-3070(.R) | -30...70 | Black |

| calHT01-2080(.R) | -20..80 | Red |

| calHT01-4060(.R) | -40...60 | Yellow |

| calHT06-4085(.R) | -40...85 | White |

|

|

| Temperature accuracy of calHT 01 and calHT 06 series | Temperature accuracy of calHT 01 and calHT 06 series |

| S | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | A | 0 | 0 | 0 | 0 | C 4 |

C 3 |

C 2 |

C 1 |

A | P |

| R/W | |||||||||||||||||||

Microcontroller requests data byte according control command and reads out

| S | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | A | D 7 |

D 6 |

D 5 |

D 4 |

D 3 |

D 2 |

D 1 |

D 0 |

N A |

P |

| S Start |

R/W

|

||||||||

| P Stop | |||||||||

| A Acknowledge | from sensor | ||||||||

| N/A No Acknowledge | |||||||||

| C 4 |

C 3 |

C 2 |

C 1 |

|

|---|---|---|---|---|

| 0 | 0 | 0 | 0 | Read-Out Humidity |

| 0 | 0 | 1 | 0 | Read-Out Temperature Byte 1 |

| 0 | 0 | 1 | 1 | Read-Out Temperature Byte 2 |

| D 7 |

D 6 |

D |

D 4 |

D 3 |

D 2 |

D 1 |

D 0 |

|

|---|---|---|---|---|---|---|---|---|

| 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | Humidity |

| 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | 0/1 | Temperature Byte 1 |

| X | X | X | X | 0/1 | 0/1 | 0/1 | 0/1 | Temperature Byte 2 |

| Symbol | Parameter | min | max | jednostka |

|---|---|---|---|---|

| tBUF | idle period between BUS actions | 4,7 | μs | |

| tD:SU | data set-up time | 250 | ns | |

| tD:HD | data hold time | 50 | ns | |

| tST:HD | start hold time | 4 | μs | |

| tST:SU | start set-up time | 4,7 | μs | |

| tSCL:L | SCL„low" time | 4,7 | μs | |

| tSCL:H | SCL „high" time | 4 | μs | |

| fSCL | SCL frequency | 100 | kHz | |

| t r | SDA, SCL LOW/HIGH time | 1 | μs | |

| tf | SDA, SCL HIGH/LOW time | 0,3 | μs | |

| tSTO:SU | stop set-up time | 4 | μs | |

| tSP | pulse width of spikes to be suppressed by input filter | 100 | ns | |

| CL | capacitive load SDA, SCL BUS (internal pull-up 120 kW) | 10 | pF | |

| tMUPD | update for measurement values | 40 | ms | |

| tSMPL | sampling period DA converter | 2 | 6 | ms |

Instrukcja użytkowania

Nigdy nie wolno dotykać aktywnej części bardzo czułego czujnika. Należy używać bardzo niskiego napięcia podczas lutowania elementu (temperatura lutowania 240°C, czas lutowania 2 sekundy). Należy oczyścić element pomiarowy delikatnie zdmuchując wszelkie pozostałości z montażu, można również przepłukać element w wodzie destylowanej. Nie wpływa to na charakterystykę czujnika, jednak dokładne pomiary mogą być dokonywane dopiero po całkowitym wysuszeniu elementu. Dotyczy to również sytuacji w której powstanie na elemencie rosa.

| Typ | FE 09/1, FE 09.R/1 FE 09/2, FE09.R/2 |

FE 09/4 FE 09.R/4 |

|---|---|---|

| Zakres działania | 0...100%rh | 0...100%rh |

| Temperatura działania FE09/X | -60...200°C | -60...200°C |

| Temperatura działania FE09.R/X | -40...110°C | -40...110°C |

| Pojemność podstawowa | 135±10pF | 115±15pF |

| Zmiana pojemności | 0,3±0,05pF/%rh | 0,27±0,08pF/%rh |

| Dopuszczalne napięcie | maks. 3V bez DC | maks. 3V bez DC |

| Częstotliwość pomiarowa | 5...200kHz | 5...200kHz |

| Współczynnik strat | <0,03 (przy 10kHz) | <0,03 (przy 50kHz) |

| Czas reakcji (T90) | 10s | 10s |

| Histereza (MR 5...95%rh) | <1,5%rh | <1,5%rh |

| Liniowość (MR 5...95%rh) | <1,5%rh | <1,5%rh |

| Stabilność długoterminowa | <1%rh/a | <1%rh/a |

| Substancja robocza | stężenie |

|---|---|

| NH3 (tylko na krótki czas) | 100 ppm (2 x MAK) |

| N2S | 20 ppm (2 x MAK) |

| SO2 | 3,7 ppm (10 x MAK) |

| No2 | 1,0 ppm (10 x MAK) |

| O2 | 0,6 ppm (10 x MAK) |

| Cl2 | brak wpływu |

Poniższy algorytm może być użyty do wyliczenia zależności temperaturowej elementu pomiarowego.

K = [A+a(T - 25)] Σ bi . T i

K= wartość skorygowana

A= sygnał wyjściowy (0...100%)

T= temperatura(ºC)

bi= 6*10-4

a= 0,04 (dla T≥25ºC)

a= 0 ( dla T<25ºC)

b0= 0,98125

b2= 6*10-6

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent