Category

Photos are for informational purposes only. View product specification

please use latin characters

Objective: Rapid heating of a steel surgical blade to 2000 °F (1093 °C) within 2 seconds to harden its edge.

Material: Stainless steel surgical blades, temperature sensing paint

Temperature: 2000 °F (1093 °C)

Frequency: 339kHz

Equipment: Ambrell 3kW induction heating system, remote heat station containing one 1.0 microfarad capacitor..

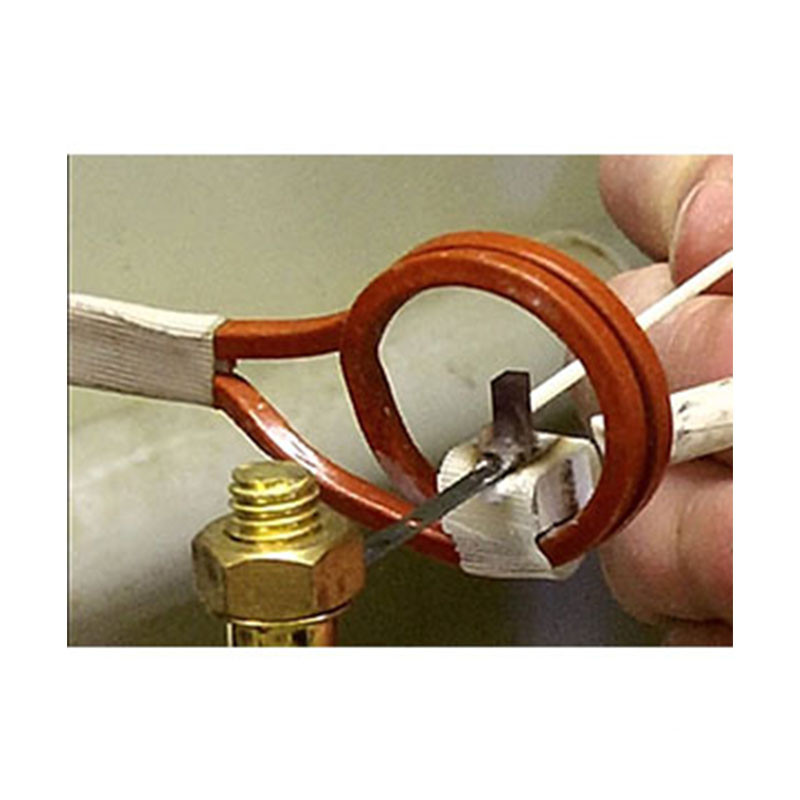

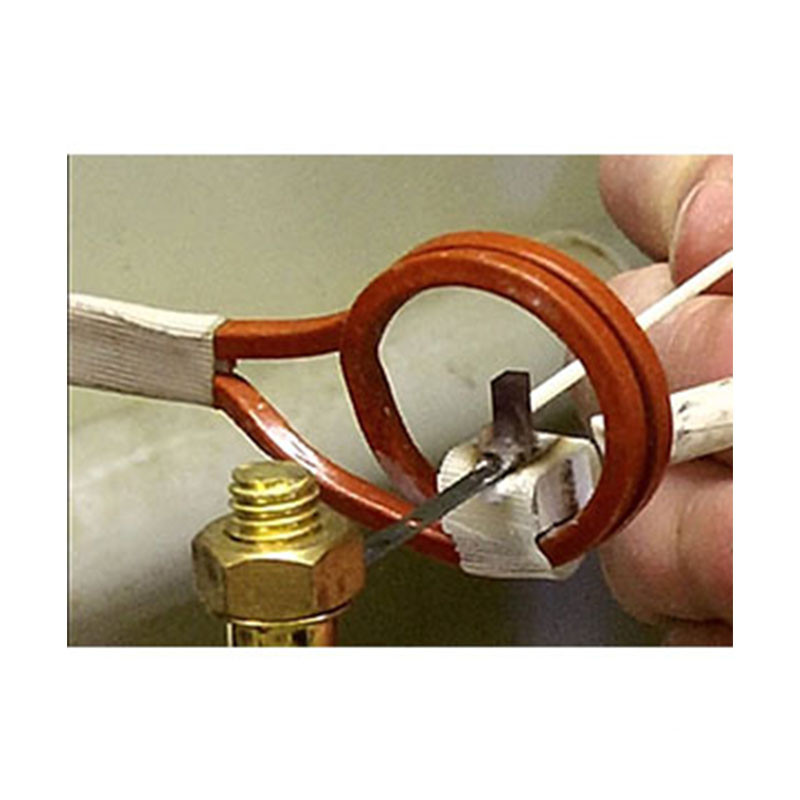

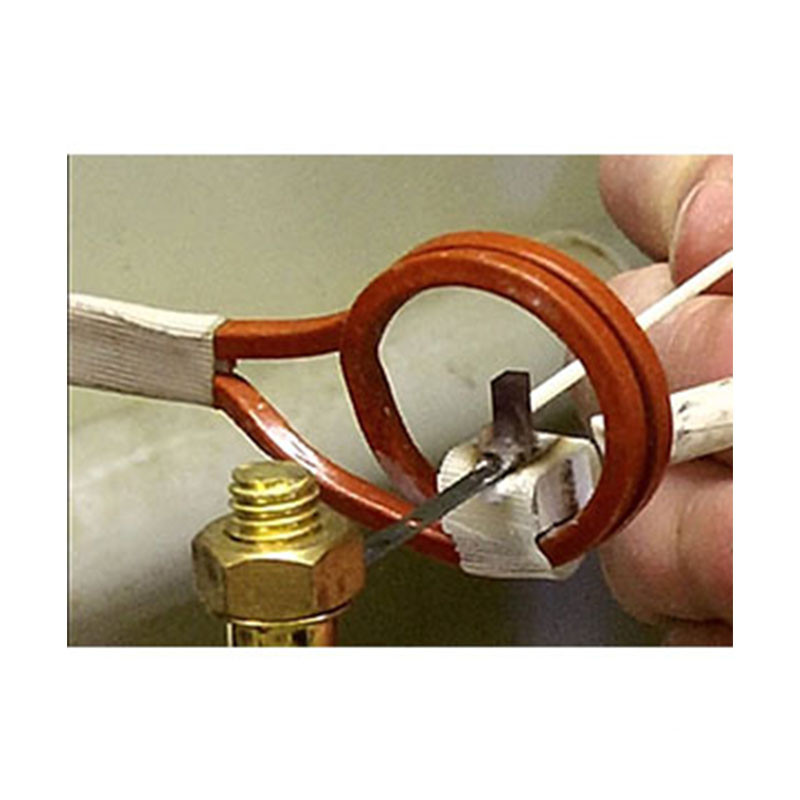

Process: A four turn helical coil is used to harden the blades. The induction coil is designed to provide uniform heat to the entire length of the blade surface. RF power is applied to heat the entire assembly. The blade reaches the necessary temperature for hardening in 1.2 seconds.

Results:

Are you interested in this product? Do you need additional information or individual pricing?

Objective: Rapid heating of a steel surgical blade to 2000 °F (1093 °C) within 2 seconds to harden its edge.

Material: Stainless steel surgical blades, temperature sensing paint

Temperature: 2000 °F (1093 °C)

Frequency: 339kHz

Equipment: Ambrell 3kW induction heating system, remote heat station containing one 1.0 microfarad capacitor..

Process: A four turn helical coil is used to harden the blades. The induction coil is designed to provide uniform heat to the entire length of the blade surface. RF power is applied to heat the entire assembly. The blade reaches the necessary temperature for hardening in 1.2 seconds.

Results:

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent