Category

Photos are for informational purposes only. View product specification

please use latin characters

|

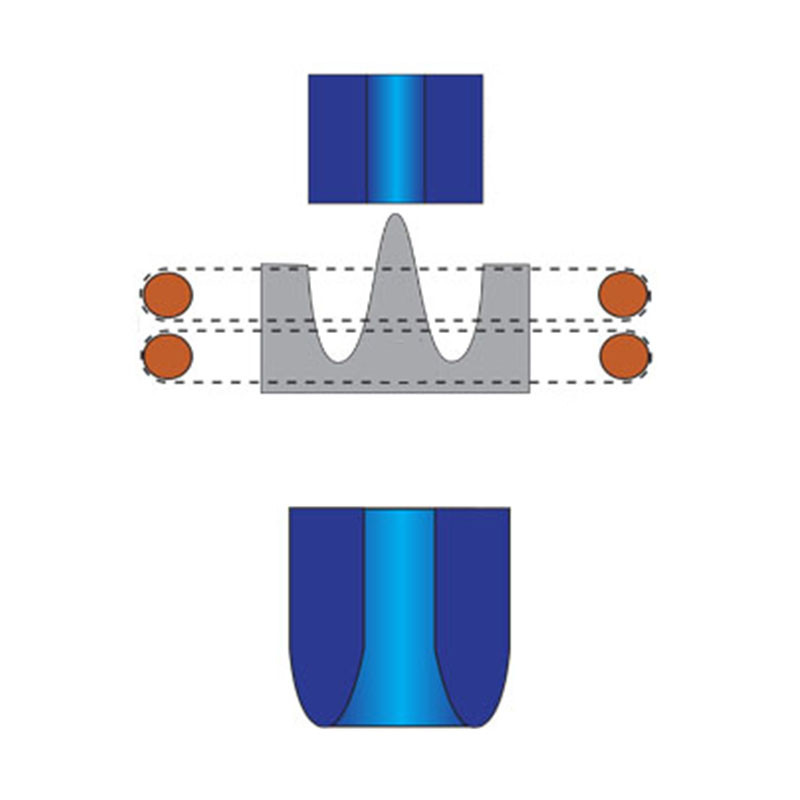

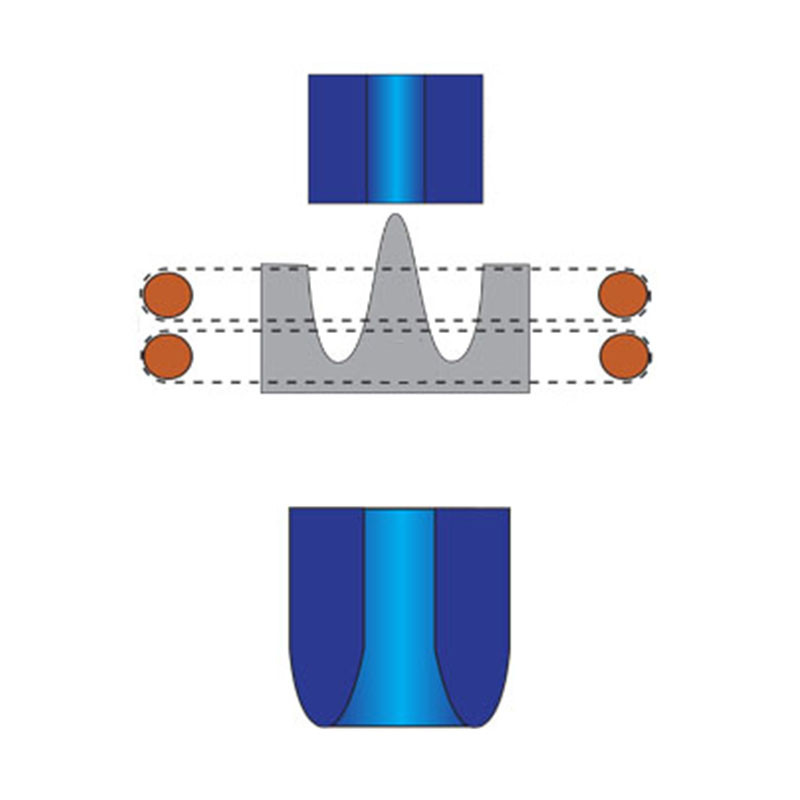

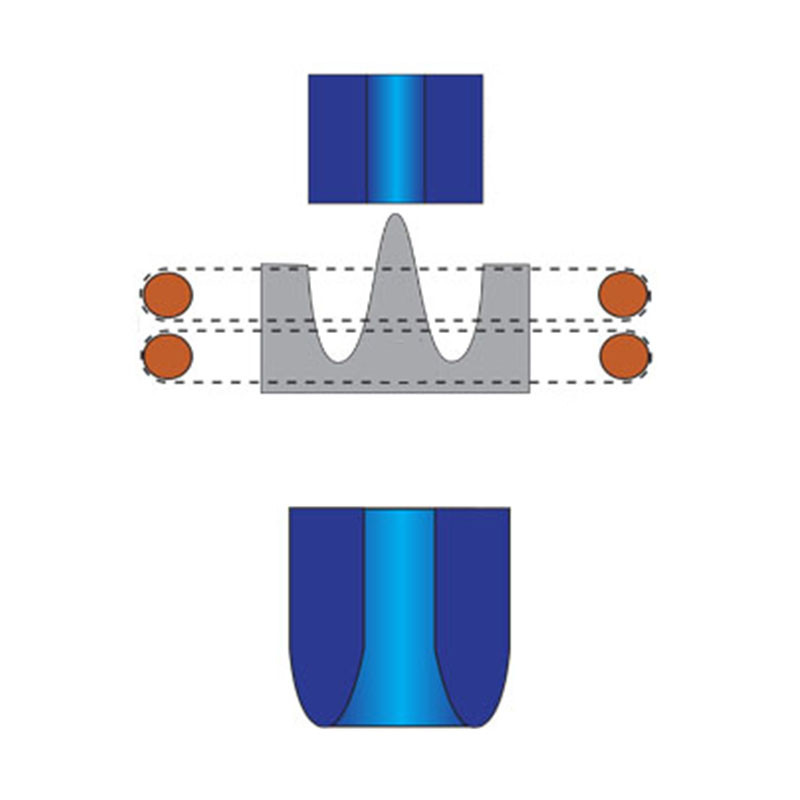

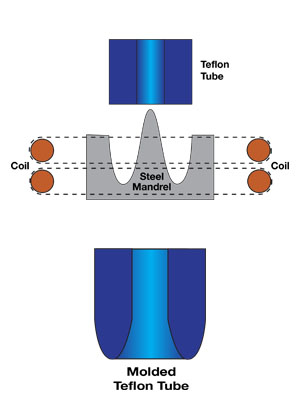

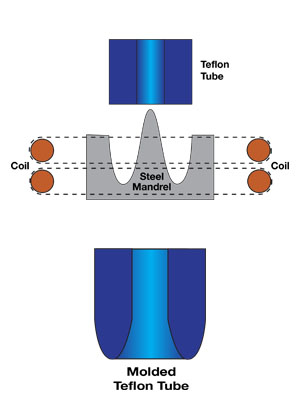

Objective: Heat a water-cooled steel mandrel to 700 °F (371 °C) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700 °F (315.6-371 ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660 °F (371.1 °C) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Are you interested in this product? Do you need additional information or individual pricing?

|

Objective: Heat a water-cooled steel mandrel to 700 °F (371 °C) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700 °F (315.6-371 ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660 °F (371.1 °C) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent