Category

Photos are for informational purposes only. View product specification

please use latin characters

Loading and unloading tanks with liquids or powders can generate static electricity, leading to sparking. This is caused by the friction of particles against each other and/or the tank walls where they are placed.

System Characteristics: The TES01 truck grounding system consists of a control unit, grounding clamp, and cable or cable drum.

Operating Principle: The StuvEx TES01-V2 grounding verification system is designed to detect low electrical resistance between the jaws of the clamp attached to the truck's grounding point. If the resistance values are low enough, TES01-V2 will allow controlled conduction of the electrostatic charge from the truck to the ground, preventing sparks. It then checks the electrical system and capacitance value at the clamp. If the capacitance matches the truck's capacitance, the green indicator lights up, and loading or unloading is permitted. TES01-V2 continuously monitors the connection between the truck and the clamping jaws to avoid the buildup of electrostatic charges. If the clamp is removed from the truck, TES01-V2 considers it a potentially hazardous situation and activates the red indicator, immediately halting loading or unloading through the lock relay.

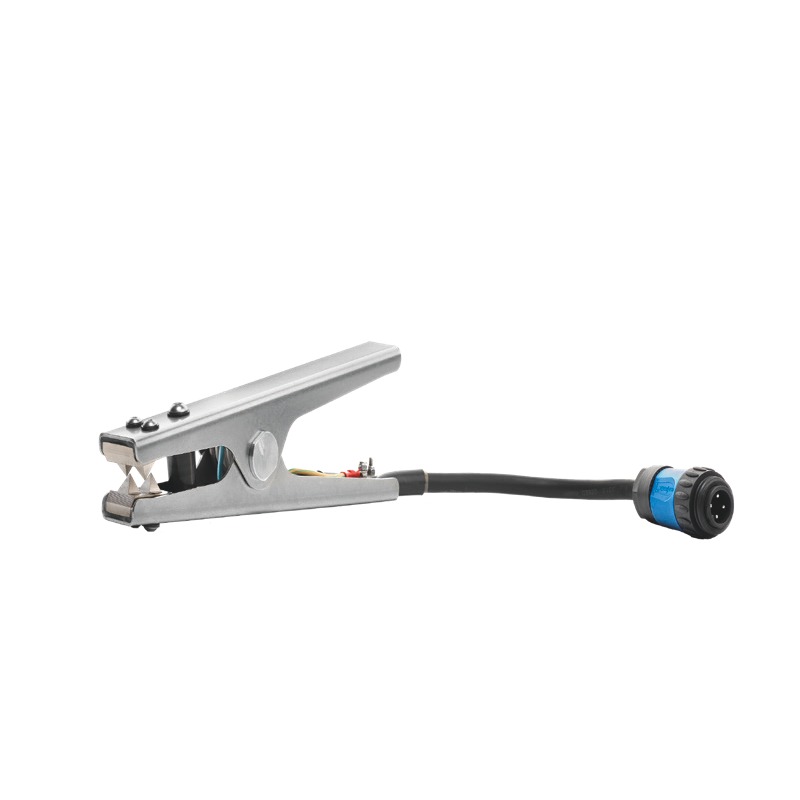

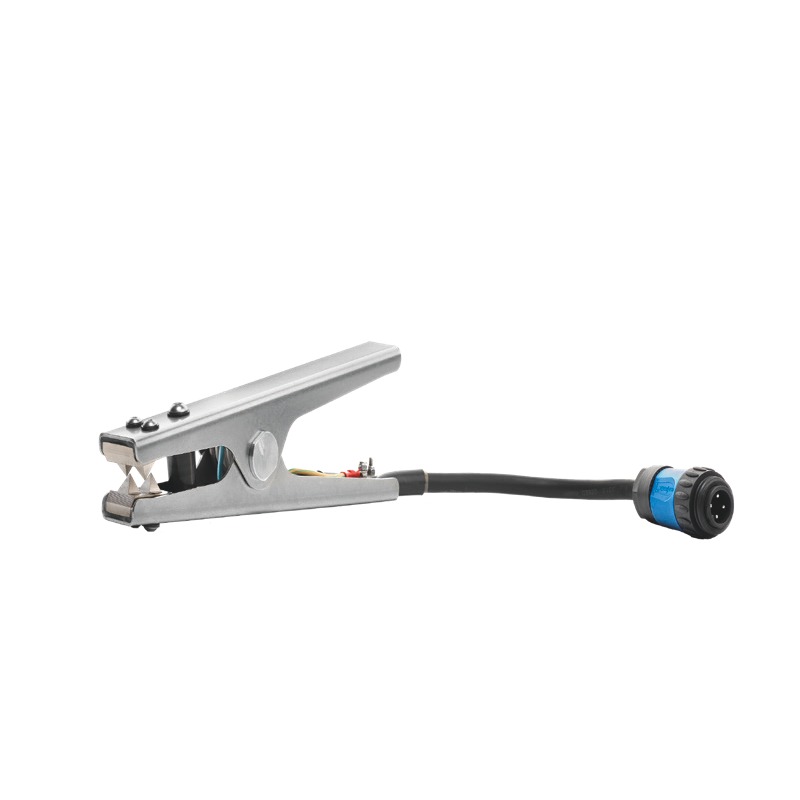

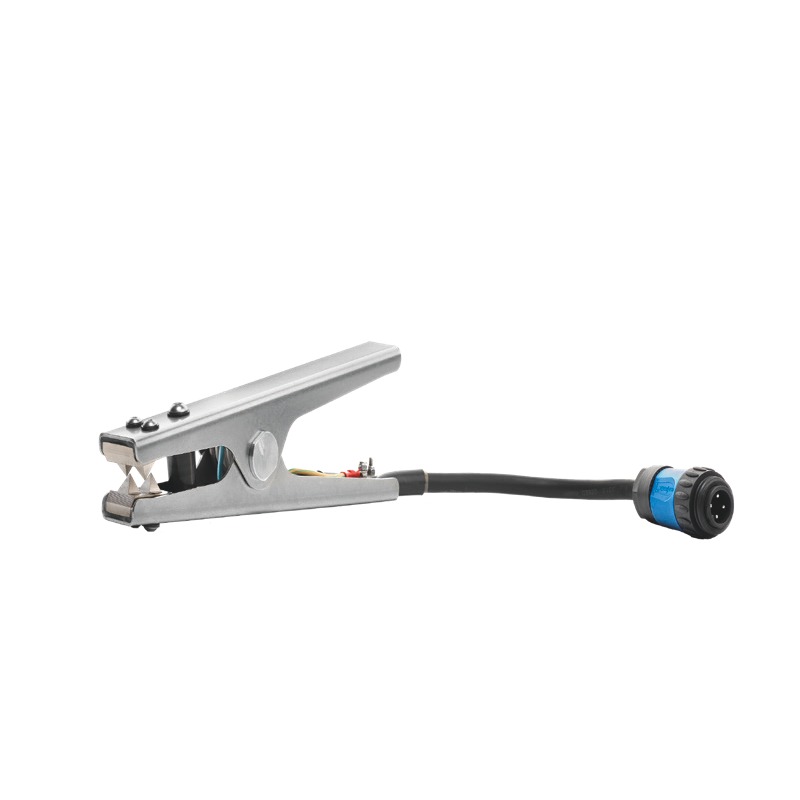

The TES01-V2 grounding system is a set comprising a control unit, cable connector, and stainless steel grounding clamp. All components have an ATEX certification.

Testing Unit Description: The control unit provides five crucial functions:

Cable, Spiral Cable, or Cable Drum: You can choose a separate cable (10 m), a spiral cable (3 – 10 m), or a cable drum (15 m) to connect TES01-V2 to the truck. The cable drum features an automatic cable unwinder.

Active Grounding Clamp: In the case of active clamps, both jaws are insulated from each other and the clamp body. Until the clamp jaw is connected to the conductor, the circuit between the clamp jaws remains open, preventing current flow. Connecting the clamp to the truck's grounding point closes the circuit, and TES01-V2 starts operating. Optional clamp storage locations can be provided with or without a cover.

Availability: Please be advised that this product is out of stock

You can place a pre-order, report your interest in the product by clicking the "Ask for availability" button.

Loading and unloading tanks with liquids or powders can generate static electricity, leading to sparking. This is caused by the friction of particles against each other and/or the tank walls where they are placed.

System Characteristics: The TES01 truck grounding system consists of a control unit, grounding clamp, and cable or cable drum.

Operating Principle: The StuvEx TES01-V2 grounding verification system is designed to detect low electrical resistance between the jaws of the clamp attached to the truck's grounding point. If the resistance values are low enough, TES01-V2 will allow controlled conduction of the electrostatic charge from the truck to the ground, preventing sparks. It then checks the electrical system and capacitance value at the clamp. If the capacitance matches the truck's capacitance, the green indicator lights up, and loading or unloading is permitted. TES01-V2 continuously monitors the connection between the truck and the clamping jaws to avoid the buildup of electrostatic charges. If the clamp is removed from the truck, TES01-V2 considers it a potentially hazardous situation and activates the red indicator, immediately halting loading or unloading through the lock relay.

The TES01-V2 grounding system is a set comprising a control unit, cable connector, and stainless steel grounding clamp. All components have an ATEX certification.

Testing Unit Description: The control unit provides five crucial functions:

Cable, Spiral Cable, or Cable Drum: You can choose a separate cable (10 m), a spiral cable (3 – 10 m), or a cable drum (15 m) to connect TES01-V2 to the truck. The cable drum features an automatic cable unwinder.

Active Grounding Clamp: In the case of active clamps, both jaws are insulated from each other and the clamp body. Until the clamp jaw is connected to the conductor, the circuit between the clamp jaws remains open, preventing current flow. Connecting the clamp to the truck's grounding point closes the circuit, and TES01-V2 starts operating. Optional clamp storage locations can be provided with or without a cover.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent