Category

Photos are for informational purposes only. View product specification

please use latin characters

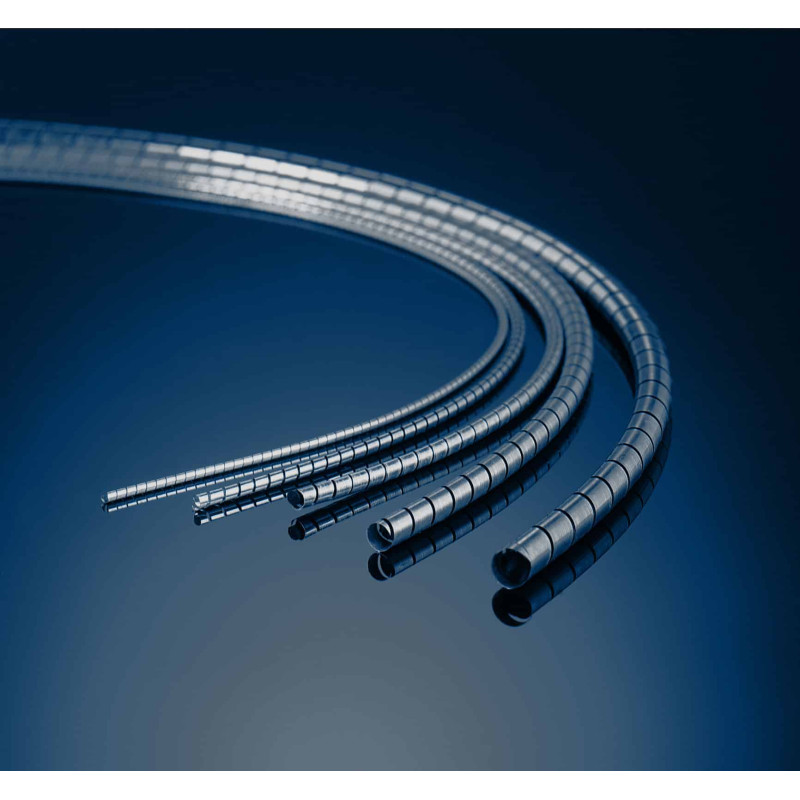

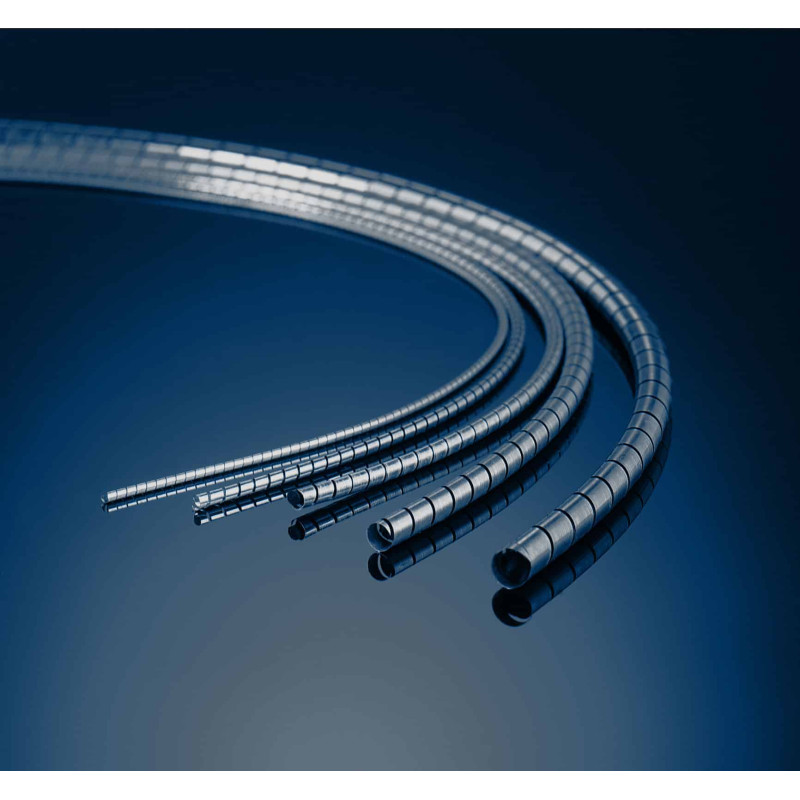

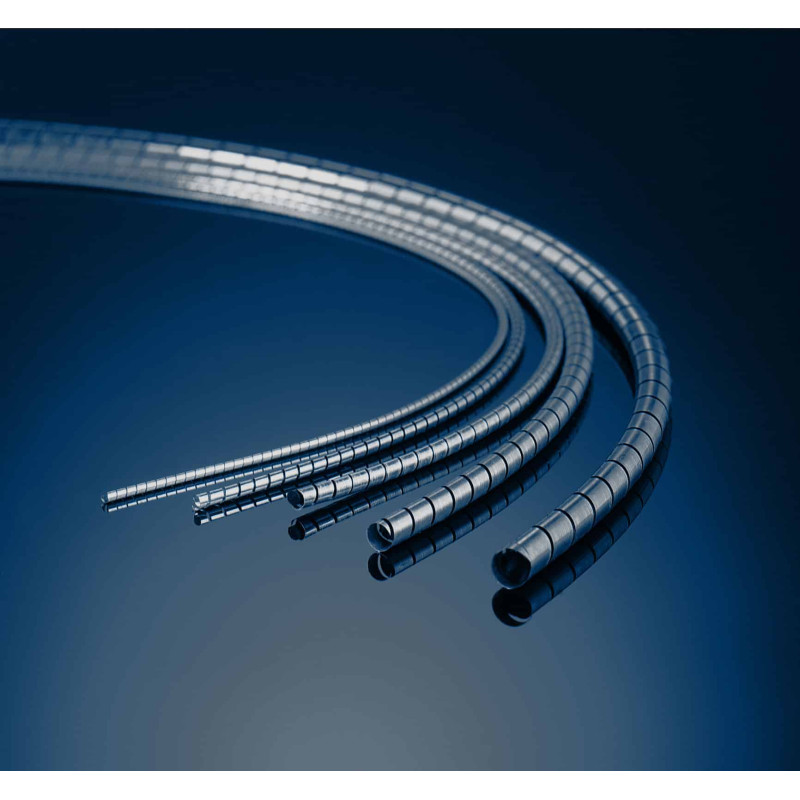

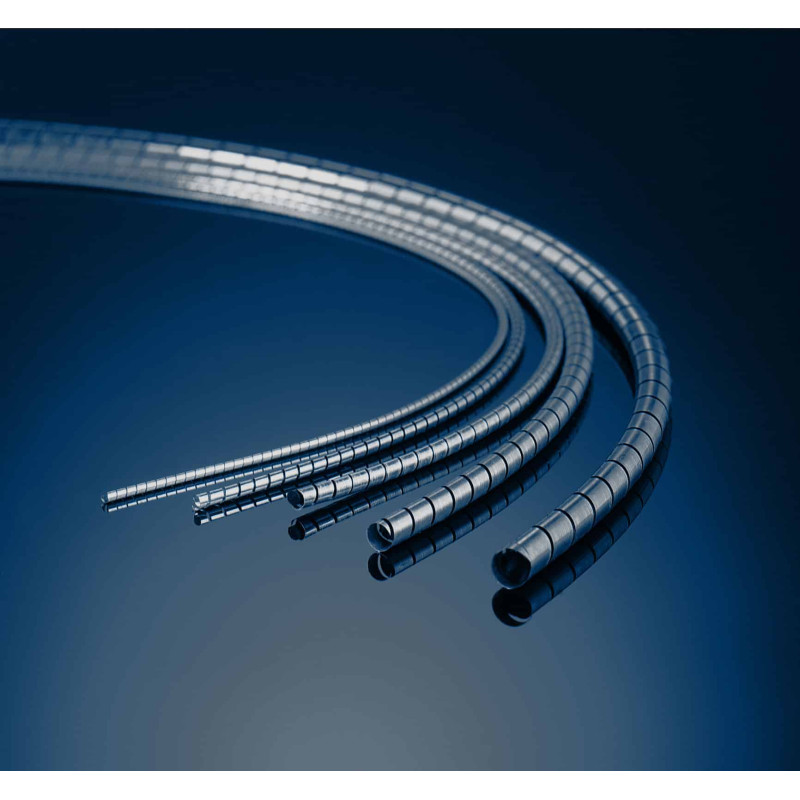

The Spira-Shield patented spiral is the basis for all of our unique high shielding EMI gasketing solutions. The spiral is wound out of spring temper beryllium copper for excellent spring memory and compression set resistance. The spiral is tin plated for superior conductivity and shielding properties. The edge plated version exhibits excellent corrosion resistance against aluminum when exposed to humid or salt-fog environments.

| Spira-Shield Part Numbers (Tin/Lead Plated Beryllium Copper) |

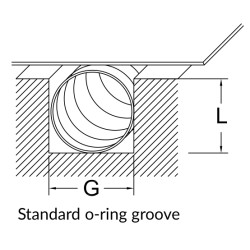

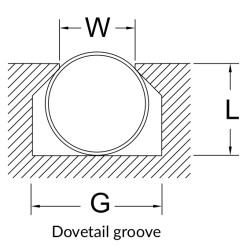

Recommended Groove Dimensions | |||||

| Diameter | Standard Force* | Moderate Force | Low Force | Depth (L) +.002”-.000” |

Width (G) +.007”-.005” |

Width (W) +.000”-.002” |

| .034” ± .002” | SS-02 | MS-02 NC** | -- | .023” | .046” | .033” |

| .047” ± .002” | SS-03 | MS-03 NC** | -- | .035” | .063” | .045” |

| .063” ± .003” | SS-04 | MS-04 | LS-04 | .046” | .094” | .060” |

| .070” ± .003” | SS-.070 | MS-.070 | LS-.070 | .053” | .094” | .067” |

| .078” ± .003” | SS-05 | MS-05 | LS-05 | .059” | .109” | .075” |

| .094” ± .004” | SS-06 | MS-06 | LS-06 | .070” | .125” | .090” |

| .103” ± .004” | SS-.103 | MS-.103 | LS-.103 | .077” | .141” | .099” |

| .109” ± .004” | SS-07 | MS-07 | LS-07 | .082” | .156” | .105” |

| .125” ± .004” | SS-08 | MS-08 | LS-08 | .094” | .171” | .121” |

| .139” ± .005” | SS-.139 | MS-.139 | LS-.139 | .104” | .187” | .134” |

| .141” ± .005” | SS-09 | MS-09 | LS-09 | .105” | .187” | .134” |

| .172” ± .005” | SS-11 | MS-11 | LS-11 | .128" | .234" | .165" |

| .187” ± .006” | SS-12 | MS-12 | LS-12 | .140" | .250" | .181" |

| .250” ± .007” | SS-16 | MS-16 | LS-16 | .185" | .343" | .240" |

| .312” ± .009” | SS-20 | MS-20 | LS-20 | .234" | .422" | .300" |

| .375” ± .011” | SS-24 | MS-24 | LS-24 | .280" | .500" | .364" |

| .500” ± .015” | -- | MS-32 | LS-32 | .375" | .656" | .485" |

Moderate and low force gaskets come with a cord unless specified otherwise. (See Options.)

* All standard force gaskets come without a cord.

** These sizes cannot be ordered with a cord.

This high-shielding gasket is well known for solving shielding problems that no other gasket can solve, and is perfect for military and aerospace projects. However, the cost is competitive enough that this gasket is also perfect for many commercial applications that require high-shielding.

Spiral: Tin/lead plated beryllium copper. (See Options for RoHS compliance). Electroplated, 90% tin, 10% lead (edges unplated).

Cord: 80 durometer PVC (hard plastic) optional, may require additional lead time.

This gasket offers shielding quality up to 165 dB. The shielding quality may vary depending on your specific application.

Spira-Shield gaskets come in three different resiliencies (as shown below). Optimal compression of the gasket is 25% of the diameter of the spiral. Since the force to compress the gasket is a function of the cube of the thickness of the beryllium copper ribbon, the compression forces shown are approximate.

Standard Force: ~30 pounds per linear inch compression.

Moderate Force: ~10 pounds per linear inch compression.

Low Force: ~1.5 pounds per linear inch compression.

This gasket is groove mounted.

We can manufacture Spira-Shield gaskets in any size diameter, from .034” up to approximately 1.5”. The functional length of the part may be small at very large diameters. Please contact us with your requirements.

Plating options can be specified by adding a prefix before the part number. (Not all plating options are in stock):

E: Edge tin/lead plating (includes edges) for high humidity or salt-fog environments

IW: RoHS compliant tin plating (Example: IWMS-08)

EIW: RoHS compliant edge tin plating for high humidity or salt-fog

Additional plating options are available by special request including: Reflow edge tin plating (R), Gold (G) and Sulfamate Nickel (N).

Moderate and low force gaskets come standard with PVC cord. The cord acts as a mechanical stop to protect the spiral from over-compression during use and handling. Specify “no cord” in the moderate and low force gaskets as follows:

NC: No Cord (Example: MS-08 NC)

All Standard Force gaskets come without cord (no NC required).

Special cords can be specified as follows (may not be available in all sizes and may include extra charges):

-F: Solid Fluorosilicone Cord (Example: MS-08-F)

-O: Space Qualified Silicone (non-outgassing)

-S: Solid Silicone Cord

-T: Thermal Plastic Rubber Cord

Spira has created three standard options to treat the splicing of material in our spool selection.

Are you interested in this product? Do you need additional information or individual pricing?

The Spira-Shield patented spiral is the basis for all of our unique high shielding EMI gasketing solutions. The spiral is wound out of spring temper beryllium copper for excellent spring memory and compression set resistance. The spiral is tin plated for superior conductivity and shielding properties. The edge plated version exhibits excellent corrosion resistance against aluminum when exposed to humid or salt-fog environments.

| Spira-Shield Part Numbers (Tin/Lead Plated Beryllium Copper) |

Recommended Groove Dimensions | |||||

| Diameter | Standard Force* | Moderate Force | Low Force | Depth (L) +.002”-.000” |

Width (G) +.007”-.005” |

Width (W) +.000”-.002” |

| .034” ± .002” | SS-02 | MS-02 NC** | -- | .023” | .046” | .033” |

| .047” ± .002” | SS-03 | MS-03 NC** | -- | .035” | .063” | .045” |

| .063” ± .003” | SS-04 | MS-04 | LS-04 | .046” | .094” | .060” |

| .070” ± .003” | SS-.070 | MS-.070 | LS-.070 | .053” | .094” | .067” |

| .078” ± .003” | SS-05 | MS-05 | LS-05 | .059” | .109” | .075” |

| .094” ± .004” | SS-06 | MS-06 | LS-06 | .070” | .125” | .090” |

| .103” ± .004” | SS-.103 | MS-.103 | LS-.103 | .077” | .141” | .099” |

| .109” ± .004” | SS-07 | MS-07 | LS-07 | .082” | .156” | .105” |

| .125” ± .004” | SS-08 | MS-08 | LS-08 | .094” | .171” | .121” |

| .139” ± .005” | SS-.139 | MS-.139 | LS-.139 | .104” | .187” | .134” |

| .141” ± .005” | SS-09 | MS-09 | LS-09 | .105” | .187” | .134” |

| .172” ± .005” | SS-11 | MS-11 | LS-11 | .128" | .234" | .165" |

| .187” ± .006” | SS-12 | MS-12 | LS-12 | .140" | .250" | .181" |

| .250” ± .007” | SS-16 | MS-16 | LS-16 | .185" | .343" | .240" |

| .312” ± .009” | SS-20 | MS-20 | LS-20 | .234" | .422" | .300" |

| .375” ± .011” | SS-24 | MS-24 | LS-24 | .280" | .500" | .364" |

| .500” ± .015” | -- | MS-32 | LS-32 | .375" | .656" | .485" |

Moderate and low force gaskets come with a cord unless specified otherwise. (See Options.)

* All standard force gaskets come without a cord.

** These sizes cannot be ordered with a cord.

This high-shielding gasket is well known for solving shielding problems that no other gasket can solve, and is perfect for military and aerospace projects. However, the cost is competitive enough that this gasket is also perfect for many commercial applications that require high-shielding.

Spiral: Tin/lead plated beryllium copper. (See Options for RoHS compliance). Electroplated, 90% tin, 10% lead (edges unplated).

Cord: 80 durometer PVC (hard plastic) optional, may require additional lead time.

This gasket offers shielding quality up to 165 dB. The shielding quality may vary depending on your specific application.

Spira-Shield gaskets come in three different resiliencies (as shown below). Optimal compression of the gasket is 25% of the diameter of the spiral. Since the force to compress the gasket is a function of the cube of the thickness of the beryllium copper ribbon, the compression forces shown are approximate.

Standard Force: ~30 pounds per linear inch compression.

Moderate Force: ~10 pounds per linear inch compression.

Low Force: ~1.5 pounds per linear inch compression.

This gasket is groove mounted.

We can manufacture Spira-Shield gaskets in any size diameter, from .034” up to approximately 1.5”. The functional length of the part may be small at very large diameters. Please contact us with your requirements.

Plating options can be specified by adding a prefix before the part number. (Not all plating options are in stock):

E: Edge tin/lead plating (includes edges) for high humidity or salt-fog environments

IW: RoHS compliant tin plating (Example: IWMS-08)

EIW: RoHS compliant edge tin plating for high humidity or salt-fog

Additional plating options are available by special request including: Reflow edge tin plating (R), Gold (G) and Sulfamate Nickel (N).

Moderate and low force gaskets come standard with PVC cord. The cord acts as a mechanical stop to protect the spiral from over-compression during use and handling. Specify “no cord” in the moderate and low force gaskets as follows:

NC: No Cord (Example: MS-08 NC)

All Standard Force gaskets come without cord (no NC required).

Special cords can be specified as follows (may not be available in all sizes and may include extra charges):

-F: Solid Fluorosilicone Cord (Example: MS-08-F)

-O: Space Qualified Silicone (non-outgassing)

-S: Solid Silicone Cord

-T: Thermal Plastic Rubber Cord

Spira has created three standard options to treat the splicing of material in our spool selection.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent