Menu

-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

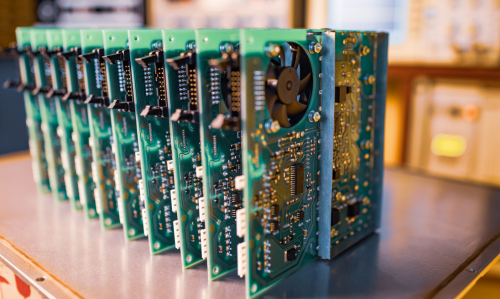

Fans

Fans – high-quality cooling and ventilation solutions

Industrial solutions, HVAC, server rooms and electronics

DACPOL — selection, delivery, service

Fans are electrical devices used for air exchange, cooling...

Fans – high-quality cooling and ventilation solutions

Industrial solutions, HVAC, server...

Read more

Fans – high-quality cooling and ventilation solutions

Industrial solutions, HVAC, server rooms and electronics

DACPOL — selection, delivery, service

Fans are electrical devices used for air exchange, cooling of machine and device components, and ensuring proper air circulation in industrial systems, HVAC, server rooms and electronics.

We offer:

Key technical parameters:

- Airflow (m³/h or CFM)

- Indicates how much air the fan can move over time. Important for cooling and ventilation of rooms.

- Static pressure (Pa)

- Relevant in systems with air resistance (ventilation ducts, filters). Radial fans achieve higher pressures than axial ones.

- Rotational speed (RPM)

- Affects noise, lifespan, and power.

- Motor power (W) and supply voltage (V)

- Selection depends on available power supply (e.g., 230 V, 400 V, 1~ or 3~).

- Noise (dB(A))

- Important in office, residential, or environments with acoustic standards.

- Housing and material

- Aluminium, steel, weather-resistant plastics; IP protection (e.g., IP54, IP65) if required.

- Bearing

- Sleeve, ball; affects lifespan and vibrations.

Why DACPOL?

- Wide assortment – from compact fans to large industrial units.

- Specialized solutions – types dedicated for HEPA filters, aggressive agents, high temperatures.

- Technical support – fan selection for specific applications.

- Quality and certificates – compliance with CE, UL, ISO standards; materials and workmanship ensuring durability.

Applications

Fans from our offer are used in:

- cooling systems for motors, converters, transformers

- air conditioning, HVAC systems, ventilation units

- server rooms and IT equipment

- industrial plants, metalworking, dryers, cooling tunnels

- … and many other places.

How to choose a fan?

- Determine the required airflow and pressure in the system.

- Check operating conditions – temperature, humidity, presence of dust or chemicals.

- Decide on material and protection class (IP, corrosion resistance).

- Consider noise level, power, and operating costs.

Related posts

Heat Management: The Key to Effective Performance and Reliability of Prototypes

31-01-2025

Posted in :

R&D

Industrial fans play a key role in heat management in electronic systems, especially in R&D environments. The...

Read more

Complementary Products

Content not available