Category

Photos are for informational purposes only. View product specification

please use latin characters

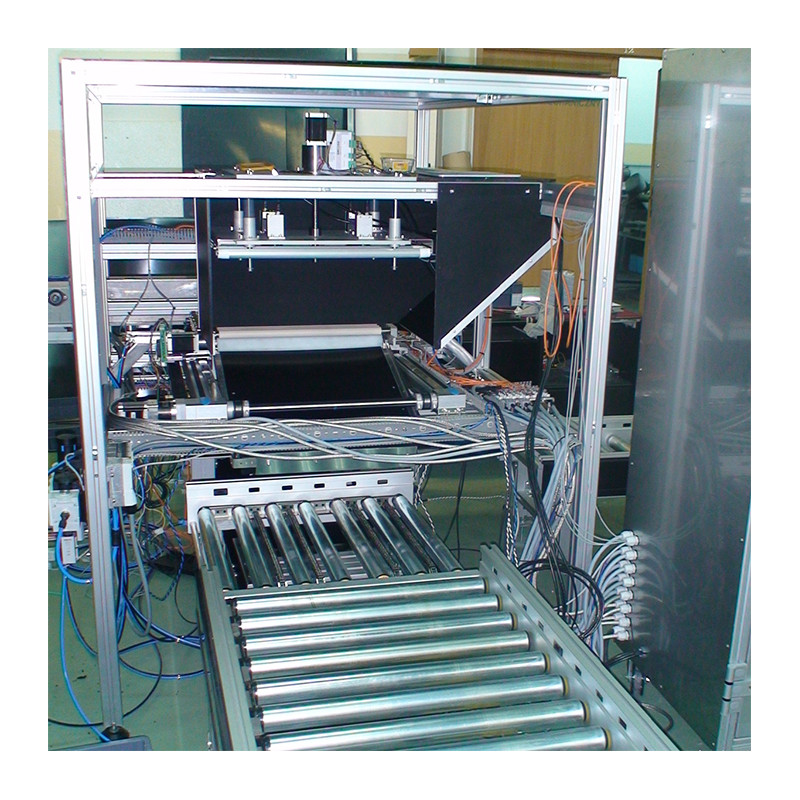

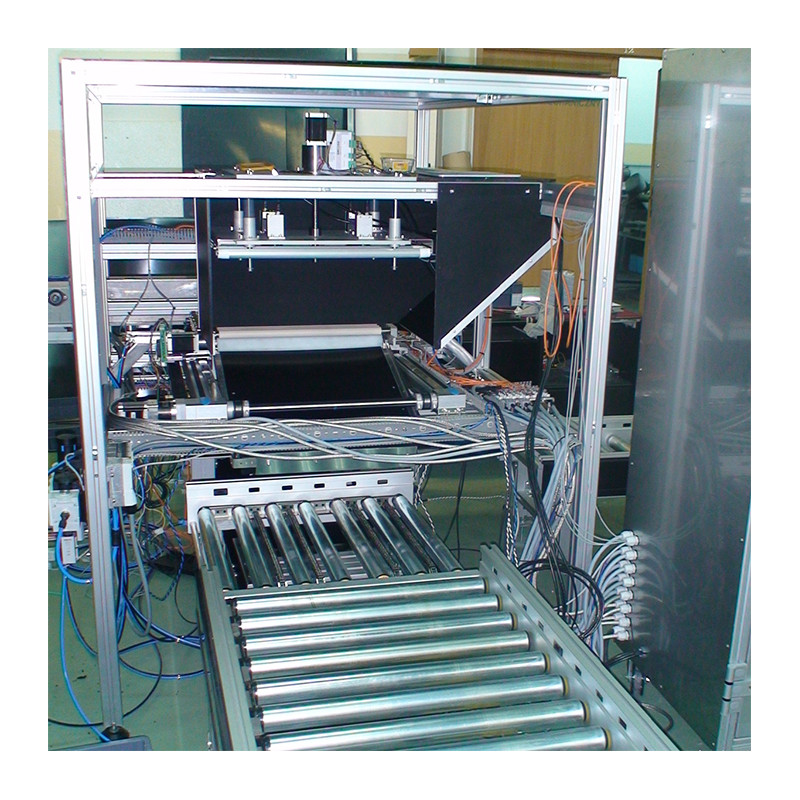

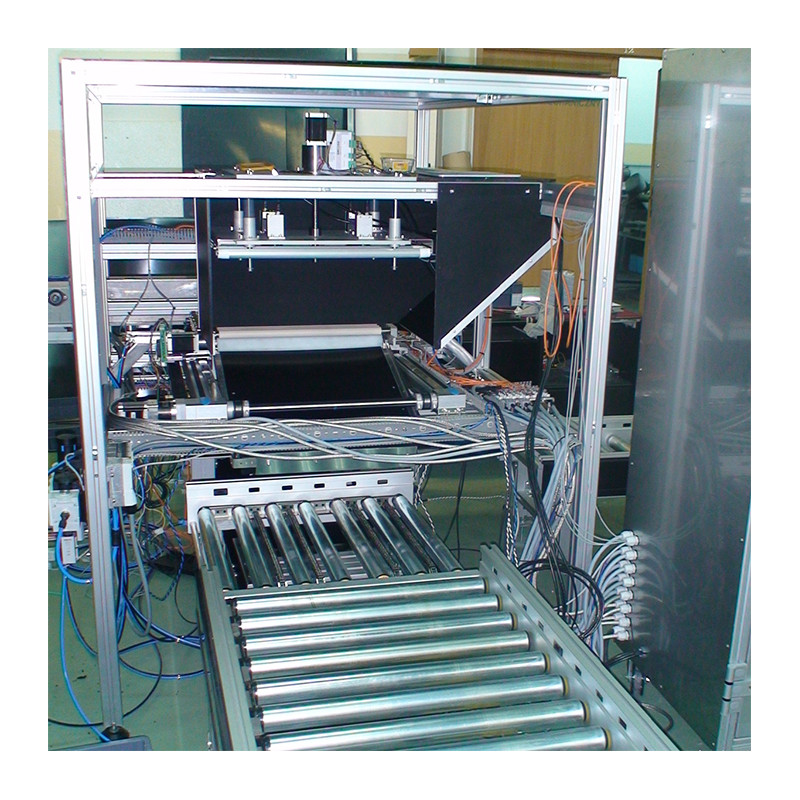

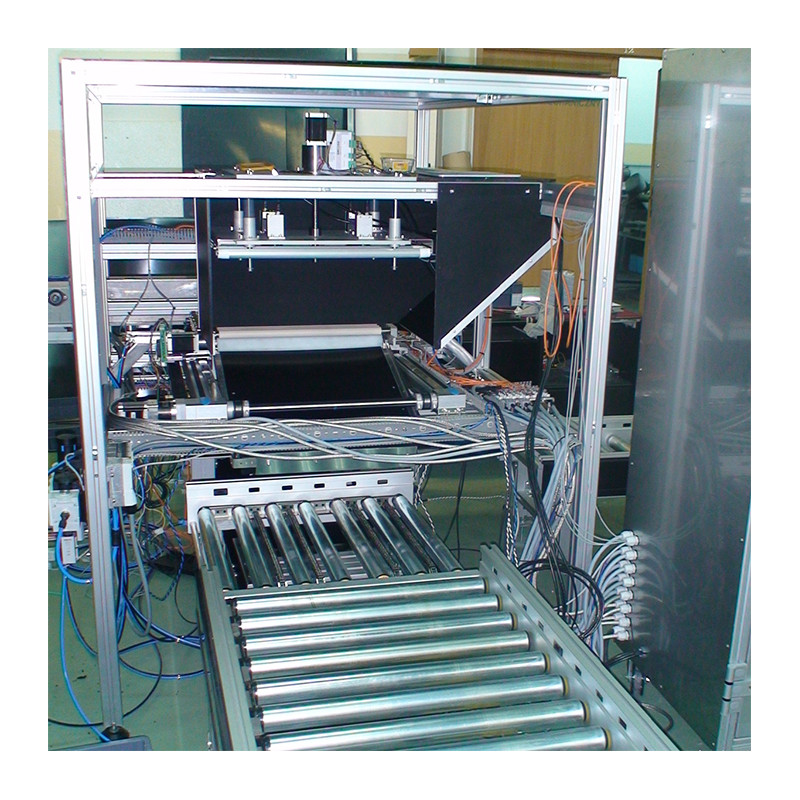

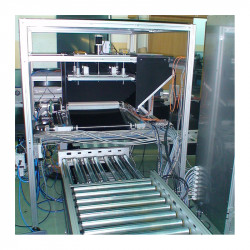

The station is used for labeling cartons of various dimensions - the only limitation is the width of the carton, which cannot exceed 500mm. Each carton is labeled on two adjacent sides - the labels are retrieved online from the client's database.

The device combines the functions of printing and applying labels to cartons moving on the conveyor. The cartons are manually placed on the conveyor and manually removed. At the input and output, the device has 2 independent lifts for raising and lowering pallets with cartons, assisting the operator. The device automatically separates the cartons on the belt to enable smooth labeling.

The labeler operates as a standalone labeling station, where label printing is triggered by reading the barcode on the carton (production tag). The printed labels are marked in the device system and blocked from being automatically reprinted, but the operator has the option to manually reprint them on an additional printer for bulk labels. Labeled cartons go to the roller conveyor, which is emptied by the operator.

Are you interested in this product? Do you need additional information or individual pricing?

The station is used for labeling cartons of various dimensions - the only limitation is the width of the carton, which cannot exceed 500mm. Each carton is labeled on two adjacent sides - the labels are retrieved online from the client's database.

The device combines the functions of printing and applying labels to cartons moving on the conveyor. The cartons are manually placed on the conveyor and manually removed. At the input and output, the device has 2 independent lifts for raising and lowering pallets with cartons, assisting the operator. The device automatically separates the cartons on the belt to enable smooth labeling.

The labeler operates as a standalone labeling station, where label printing is triggered by reading the barcode on the carton (production tag). The printed labels are marked in the device system and blocked from being automatically reprinted, but the operator has the option to manually reprint them on an additional printer for bulk labels. Labeled cartons go to the roller conveyor, which is emptied by the operator.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent