Category

Photos are for informational purposes only. View product specification

please use latin characters

|

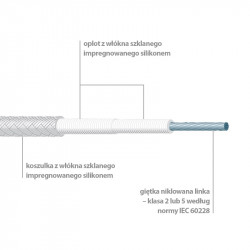

Characteristics • Continuous operating temperatures: -60 °C to +400 °C• Good resistance to thermal shocks and oxidization. • Rated voltage: 300/500 V. • Test voltage: 2000 V. Standard products • Standard colour: grey• Other colours on request including yellow/green. Approvals - standards • Nickel-plated copper complying with the 2 % class as per standard ASTM B355 Applications • Cabling for heating resistors, cartridges, bands and plates. Options • Bare copper core: ref. VAS.• Nickel-plated copper core complying with the 27 % class as per standard ASTM B355 for reinforced resistance to oxidization: contact us. • Other nominal cross-sections: contact us. • Other options: contact us. |

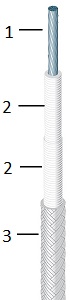

1 • Stranded or flexible nickel-plated copper core – class 2 or 5 as per IEC 60228. |

| Nominal cross-section [mm2] |

Nominal stranding | Maximum linear resistance at 20 °C [Ω/km] |

Nominal diameter [mm] |

Approximate linear weight [kg/km] |

|---|---|---|---|---|

| 0,25 | 8 x 0,20 | 87,2 | 2,2 | 7,9 |

| 0,34 | 7 x 0,25 | 63,6 | 2,3 | 9,2 |

| 0,5 | 7 x 0,30 | 40,1 | 2,5 | 11,1 |

| 0,75 | 11 x 0,30 | 26,7 | 2,7 | 14,3 |

| 1 | 14 x 0,30 | 20,0 | 3,2 | 19,9 |

| 1,5 | 21 x 0,30 | 13,7 | 3,4 | 25,6 |

| 2,5 | 35 x 0,30 | 8,21 | 4,0 | 36,4 |

| 4 | 56 x 0,30 | 5,09 | 4,5 | 56,3 |

| 6 | 84 x 0,30 | 3,39 | 5,0 | 73,9 |

| 10 | 80 x 0,40 | 1,95 | 8,0 | 149 |

| 16 | 126 x 0,40 | 1,24 | 9,0 | 225 |

| 25 | 196 x 0,40 | 0,795 | 10,6 | 321 |

| 35 | 276 x 0,40 | 0,565 | 13,0 | 442 |

| 50 | 396 x 0,40 | 0,393 | 14,4 | 576 |

| 70 | 543 x 0,40 | 0,277 | 16,5 | 827 |

| 95 | 740 x 0,40 | 0,210 | 18,5 | 1102 |

| 120 | 925 x 0,40 | 0,164 | 20,2 | 1327 |

| 150 | 1184 x 0,40 | 0,132 | 23,0 | 1741 |

| 185 | 1443 x 0,40 | 0,108 | 25,9 | 2061 |

| 240 | 1924 x0,40 | 0,0817 | 27,9 | 2666 |

Are you interested in this product? Do you need additional information or individual pricing?

|

Characteristics • Continuous operating temperatures: -60 °C to +400 °C• Good resistance to thermal shocks and oxidization. • Rated voltage: 300/500 V. • Test voltage: 2000 V. Standard products • Standard colour: grey• Other colours on request including yellow/green. Approvals - standards • Nickel-plated copper complying with the 2 % class as per standard ASTM B355 Applications • Cabling for heating resistors, cartridges, bands and plates. Options • Bare copper core: ref. VAS.• Nickel-plated copper core complying with the 27 % class as per standard ASTM B355 for reinforced resistance to oxidization: contact us. • Other nominal cross-sections: contact us. • Other options: contact us. |

1 • Stranded or flexible nickel-plated copper core – class 2 or 5 as per IEC 60228. |

| Nominal cross-section [mm2] |

Nominal stranding | Maximum linear resistance at 20 °C [Ω/km] |

Nominal diameter [mm] |

Approximate linear weight [kg/km] |

|---|---|---|---|---|

| 0,25 | 8 x 0,20 | 87,2 | 2,2 | 7,9 |

| 0,34 | 7 x 0,25 | 63,6 | 2,3 | 9,2 |

| 0,5 | 7 x 0,30 | 40,1 | 2,5 | 11,1 |

| 0,75 | 11 x 0,30 | 26,7 | 2,7 | 14,3 |

| 1 | 14 x 0,30 | 20,0 | 3,2 | 19,9 |

| 1,5 | 21 x 0,30 | 13,7 | 3,4 | 25,6 |

| 2,5 | 35 x 0,30 | 8,21 | 4,0 | 36,4 |

| 4 | 56 x 0,30 | 5,09 | 4,5 | 56,3 |

| 6 | 84 x 0,30 | 3,39 | 5,0 | 73,9 |

| 10 | 80 x 0,40 | 1,95 | 8,0 | 149 |

| 16 | 126 x 0,40 | 1,24 | 9,0 | 225 |

| 25 | 196 x 0,40 | 0,795 | 10,6 | 321 |

| 35 | 276 x 0,40 | 0,565 | 13,0 | 442 |

| 50 | 396 x 0,40 | 0,393 | 14,4 | 576 |

| 70 | 543 x 0,40 | 0,277 | 16,5 | 827 |

| 95 | 740 x 0,40 | 0,210 | 18,5 | 1102 |

| 120 | 925 x 0,40 | 0,164 | 20,2 | 1327 |

| 150 | 1184 x 0,40 | 0,132 | 23,0 | 1741 |

| 185 | 1443 x 0,40 | 0,108 | 25,9 | 2061 |

| 240 | 1924 x0,40 | 0,0817 | 27,9 | 2666 |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent