Category

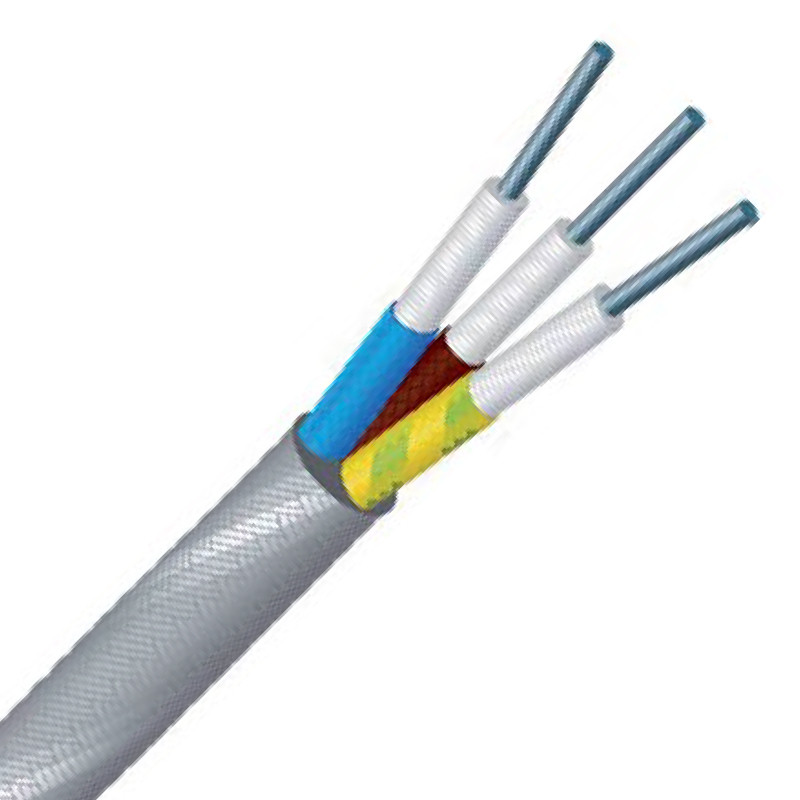

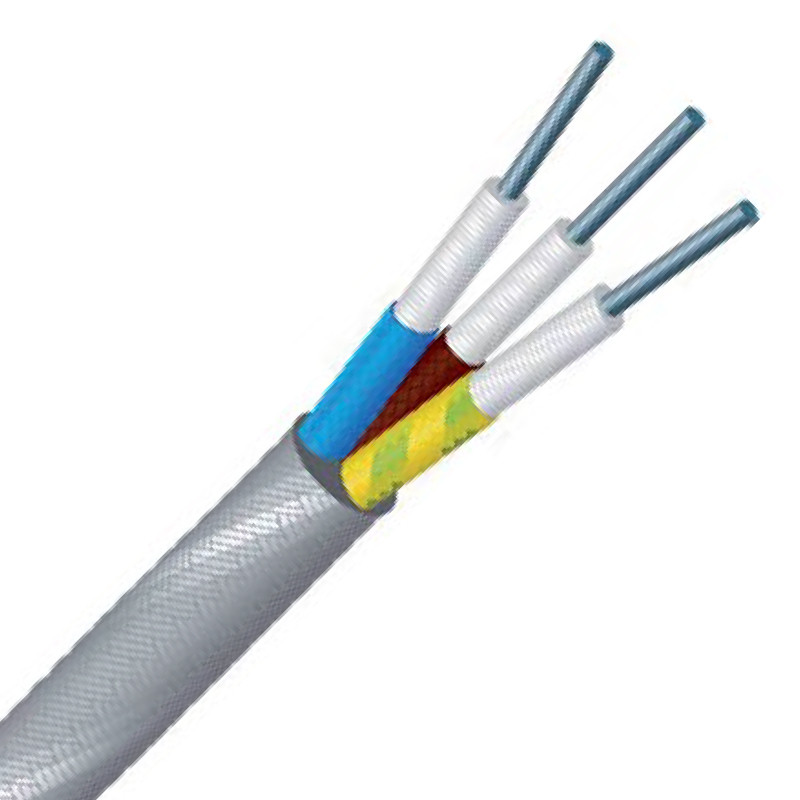

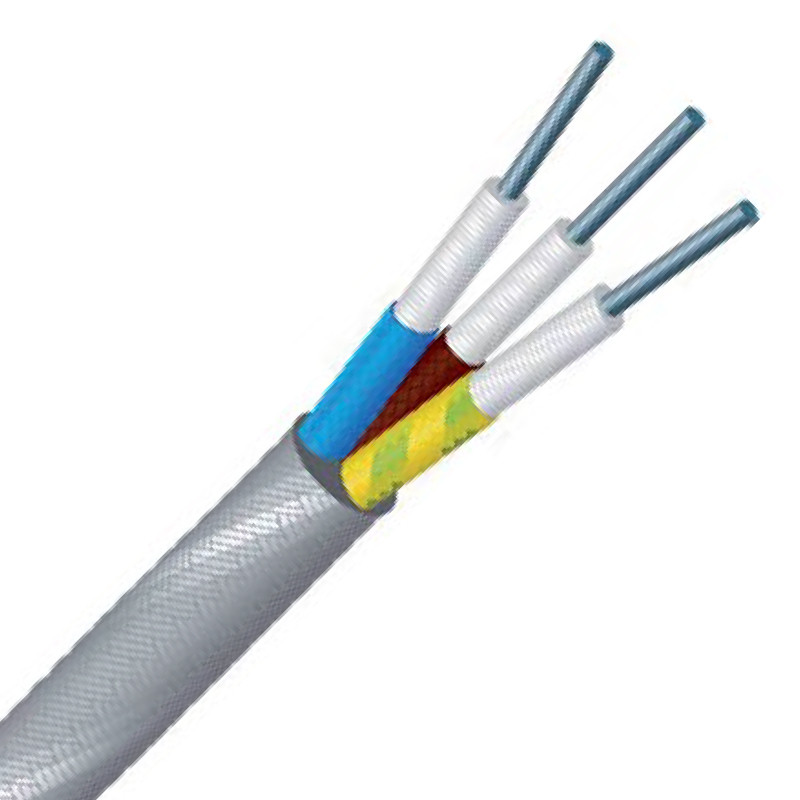

Photos are for informational purposes only. View product specification

please use latin characters

Characteristics

Standard products

Approvals - standards

Applications

Options

> Galvanised steel braid: ref. BGMA-CNVS.

> Stainless steel braid: ref. BIMA-CNVS

> Nickel-plated copper braid: ref. MABCN-CNVS.

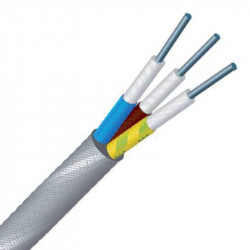

1 • Stranded nickel-plated copper core.

2 • Silicone impregnated fibreglass lappings.

3 • Silicone-coated fibreglass braid.

4 • Fillers optional, not shown.

5 • Silicone-coated mineral fibre braid.

| Standard conductor colours | ||

|---|---|---|

| Number of conductors | With an earth wire | Without an earth wire |

| 2 | - | Blue – Brown |

| 3 | Yellow - Green – Blue – Brown | Brown – Black – Grey (or Blue) |

| 4 | Yellow - Green – Brown – Black – Grey (or Blue) | Blue – Brown – Black – Grey |

| 5 | Yellow - Green – Blue – Brown – Black – Grey (or Red) | Blue – Brown – Black – Grey – Black (or Red) |

| ≥6 | Yellow - Green – Black or White non-numbered | Black or Grey non-numbered |

Conducting core |

INSULATED CONDUCTORS |

SHEATHED CABLE |

||||

|---|---|---|---|---|---|---|

| Nominal cross-section (mm2) | Nominal stranding | Maximum linear resistance at 20 °C (Ω/km) | Nominal thickness of insulation (mm | Nominal diameter of the conductor (mm | Nominal diameter of the cable (mm) | Approximate linear weight (kg/km) |

| 2 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 5.6 | 27.4 |

| 3 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 5.9 | 39.8 |

| 4 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 6.5 | 52.8 |

| 5 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 7.1 | 66.0 |

| 7 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 7.7 | 92.5 |

| 2 x 0.75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 6.3 | 33.9 |

| 3 x 0.75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 6.6 | 49.9 |

| 4 x 0.75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 7.2 | 64.9 |

| 5 x 0,75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 7.9 | 83.4 |

| 7 x 0,75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 8.6 | 116 |

| 2 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 6.4 | 47.7 |

| 3 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 6.8 | 59.0 |

| 4 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 7.4 | 77.0 |

| 5 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 8.1 | 98.5 |

| 7 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 8.9 | 131 |

| 12 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 11.8 | 223 |

| 19 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 13.9 | 340 |

| 24 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 16.4 | 430 |

| 27 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 16.8 | 483 |

| 37 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 19.0 | 661 |

| 2 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 7.2 | 59.6 |

| 3 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 7.4 | 81.2 |

| 4 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 8.2 | 100 |

| 5 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 9.0 | 131 |

| 7 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 9.8 | 171 |

| 12 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 13.0 | 293 |

| 19 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 15.4 | 465 |

| 24 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 18.2 | 586 |

| 27 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 18.6 | 660 |

| 37 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 21.1 | 905 |

| 2 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 7.8 | 77.0 |

| 3 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 8.3 | 113 |

| 4 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 9.1 | 150 |

| 5 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 10.1 | 193 |

| 7 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 11.2 | 256 |

| 12 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 21.2 | 437 |

| 2 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 9.4 | 130 |

| 3 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 10.0 | 182 |

| 4 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 11.1 | 238 |

| 5 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 12.2 | 308 |

| 7 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 13.4 | 409 |

| 2 x 6 | 84 x 0.30 | 3.11 | 0.8 | 4.6 | 10.6 | 184 |

| 3 x 6 | 84 x 0.30 | 3.11 | 0.8 | 4.6 | 11.3 | 256 |

| 4 x 6 | 84 x 0.30 | 3.11 | 0.8 | 4.6 | 12.8 | 343 |

| 5 x 6 | 84 x 0.30 | 3.11 | 0.8 | 4.6 | 13.9 | 428 |

| 2 x 10 | 80 x 0.40 | 1.84 | 1.2 | 6.6 | 14.6 | 310 |

| 3 x 10 | 80 x 0.40 | 1.84 | 1.2 | 6.6 | 15.4 | 431 |

| 4 x 10 | 80 x 0.40 | 1.84 | 1.2 | 6.6 | 17.5 | 570 |

Are you interested in this product? Do you need additional information or individual pricing?

Characteristics

Standard products

Approvals - standards

Applications

Options

> Galvanised steel braid: ref. BGMA-CNVS.

> Stainless steel braid: ref. BIMA-CNVS

> Nickel-plated copper braid: ref. MABCN-CNVS.

1 • Stranded nickel-plated copper core.

2 • Silicone impregnated fibreglass lappings.

3 • Silicone-coated fibreglass braid.

4 • Fillers optional, not shown.

5 • Silicone-coated mineral fibre braid.

| Standard conductor colours | ||

|---|---|---|

| Number of conductors | With an earth wire | Without an earth wire |

| 2 | - | Blue – Brown |

| 3 | Yellow - Green – Blue – Brown | Brown – Black – Grey (or Blue) |

| 4 | Yellow - Green – Brown – Black – Grey (or Blue) | Blue – Brown – Black – Grey |

| 5 | Yellow - Green – Blue – Brown – Black – Grey (or Red) | Blue – Brown – Black – Grey – Black (or Red) |

| ≥6 | Yellow - Green – Black or White non-numbered | Black or Grey non-numbered |

Conducting core |

INSULATED CONDUCTORS |

SHEATHED CABLE |

||||

|---|---|---|---|---|---|---|

| Nominal cross-section (mm2) | Nominal stranding | Maximum linear resistance at 20 °C (Ω/km) | Nominal thickness of insulation (mm | Nominal diameter of the conductor (mm | Nominal diameter of the cable (mm) | Approximate linear weight (kg/km) |

| 2 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 5.6 | 27.4 |

| 3 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 5.9 | 39.8 |

| 4 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 6.5 | 52.8 |

| 5 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 7.1 | 66.0 |

| 7 x 0.5 | 7 x 0.30 | 36.7 | 0.6 | 2.1 | 7.7 | 92.5 |

| 2 x 0.75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 6.3 | 33.9 |

| 3 x 0.75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 6.6 | 49.9 |

| 4 x 0.75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 7.2 | 64.9 |

| 5 x 0,75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 7.9 | 83.4 |

| 7 x 0,75 | 11 x 0.30 | 24.8 | 0.6 | 2.4 | 8.6 | 116 |

| 2 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 6.4 | 47.7 |

| 3 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 6.8 | 59.0 |

| 4 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 7.4 | 77.0 |

| 5 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 8.1 | 98.5 |

| 7 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 8.9 | 131 |

| 12 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 11.8 | 223 |

| 19 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 13.9 | 340 |

| 24 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 16.4 | 430 |

| 27 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 16.8 | 483 |

| 37 x 1 | 14 x 0,30 | 18.2 | 0.6 | 2.5 | 19.0 | 661 |

| 2 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 7.2 | 59.6 |

| 3 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 7.4 | 81.2 |

| 4 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 8.2 | 100 |

| 5 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 9.0 | 131 |

| 7 x 1,5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 9.8 | 171 |

| 12 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 13.0 | 293 |

| 19 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 15.4 | 465 |

| 24 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 18.2 | 586 |

| 27 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 18.6 | 660 |

| 37 x 1.5 | 21 x 0.30 | 12.2 | 0.6 | 2.8 | 21.1 | 905 |

| 2 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 7.8 | 77.0 |

| 3 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 8.3 | 113 |

| 4 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 9.1 | 150 |

| 5 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 10.1 | 193 |

| 7 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 11.2 | 256 |

| 12 x 2.5 | 35 x 0.30 | 7.56 | 0.6 | 3.2 | 21.2 | 437 |

| 2 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 9.4 | 130 |

| 3 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 10.0 | 182 |

| 4 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 11.1 | 238 |

| 5 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 12.2 | 308 |

| 7 x 4 | 56 x 0.30 | 4.70 | 0.8 | 4.0 | 13.4 | 409 |

| 2 x 6 | 84 x 0.30 | 3.11 | 0.8 | 4.6 | 10.6 | 184 |

| 3 x 6 | 84 x 0.30 | 3.11 | 0.8 | 4.6 | 11.3 | 256 |

| 4 x 6 | 84 x 0.30 | 3.11 | 0.8 | 4.6 | 12.8 | 343 |

| 5 x 6 | 84 x 0.30 | 3.11 | 0.8 | 4.6 | 13.9 | 428 |

| 2 x 10 | 80 x 0.40 | 1.84 | 1.2 | 6.6 | 14.6 | 310 |

| 3 x 10 | 80 x 0.40 | 1.84 | 1.2 | 6.6 | 15.4 | 431 |

| 4 x 10 | 80 x 0.40 | 1.84 | 1.2 | 6.6 | 17.5 | 570 |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent