Slip Rotary Connectors (Slip Rings)

In DACPOL's offer, we have many types of slip rings from leading manufacturers, such as Moflon. Our products, due to their manufacturers, stand out for their high reliability and long lifespan. Electric slip rings are used in many industries to improve work efficiency. The parameters of our devices match those from the manufacturers' datasheets, which translates to the safety of the installations where they are installed.

Application of electric slip rings

Slip rings, also known as electric slip rings, are most commonly used in electromechanical devices that require the transmission of electrical signals to rotating components. The signal transferred by the slip rings is continuously transmitted with any number of rotations in any direction.

Electric slip rings, which can also be found under other names such as: rotary pass-throughs, commutator connectors, brush connectors, or electric rotary connectors. Engineers also use English terms like slip rings, rotary electrical, collector, swivel, electrical rotary joint interface, commutator.

The slip rings offered by our company have high durability, which directly contributes to their long lifespan. Their special construction ensures that the brushes do not require additional lubrication or other maintenance. Slip rings are, by nature, maintenance-free products.

Application of slip rings

Slip rings are used, among other things, in solutions such as:

- industrial machines

- advertising and exhibition machines, devices

- wind turbines, generators

- surveillance systems

- process control systems

- medical equipment

- rotary, indexing tables

- packaging machines/winders

- automatic systems, manipulators

- cable/wire winding/unwinding systems

- robotics

How are slip rings constructed?

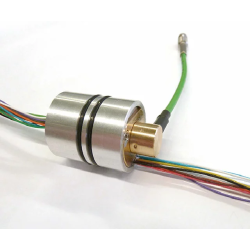

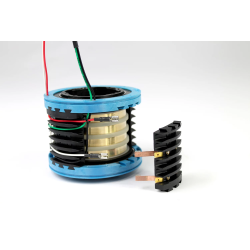

Electric slip rings consist of a stationary part and a rotating part. The first is the stator, while the second is the rotor. These two elements are separated by an insulating material, which prevents electrical contact between them.

The rotor is equipped with conductive slip rings, which are electrically isolated from each other, allowing them to operate independently. Each of them is assigned a brush located on the stator, made of materials with low friction and high electrical conductivity. This design allows electric slip rings to effectively transmit signals continuously and reliably.

How do slip rings work?

Electric slip rings provide the possibility of transmitting signals and power between the rotating construction and the stationary source. This eliminates the need for cables, which could interfere with the smoothness of the rotating motion.

The principle of operation of slip rings is based on maintaining an electrical contact between the brushes on the stator, which are responsible for transmitting the signal during rotation, and the rings. When the rotor rotates, the brushes slide over the ring, ensuring the flow of electricity.

Slip rings are also designed so that each ring is responsible for handling a separate circuit. This allows them to transmit various signals and power simultaneously. Therefore, rotary connectors for industrial machines available in DACPOL's offer can perform tasks related to power supply, control, and data transmission in electrical devices simultaneously as a single component.

Advantages of slip rings in signal transmission

Although touchless transmission solutions are becoming more popular for devices that require signal transmission, the electric slip rings still have many advantages.

Firstly, these components are not susceptible to interfering radiation like solutions based on Bluetooth, radio transmission, or infrared technology. As a result, they are highly effective and reliable in this regard.

What slip rings are available in DACPOL?

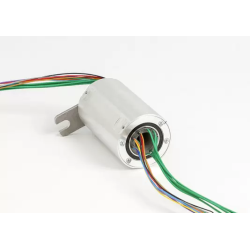

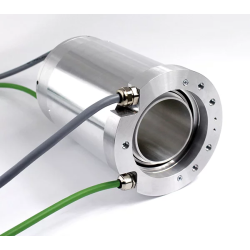

In DACPOL, we offer electric slip rings designed for various applications. Among the types, there are waterproof models with an IP68 protection class, designed to work underwater both in terms of construction and wiring, as well as those designed for use in fiber-optic installations. Additionally, you will find slip rings with a through hole, modular, miniature, or equipped with a flange. Thanks to this, you can easily match them to devices, regardless of the industry or working conditions they are meant to be used in.

Electric rotary connectors vs. other signal transmission solutions

Compared to wired or touchless signal transmission, electric rotary connectors primarily allow for uninterrupted power transfer without the risk of disconnection during rotational movement. This makes electromechanical devices where they are used less prone to failures and signal loss.

The design and operating characteristics of electric rotary connectors also make them suitable for places where full 360-degree rotations occur. Their use eliminates the problem of tangled wires. Electric rotary connectors, due to the elimination of wires, are also less susceptible to electrical short circuits.

How to select an electric rotary connector?

Among the important parameters to consider when selecting an electric rotary connector are:

- the number of circuits,

- rated voltage,

- rated current,

- maximum working speed.

The first parameter refers to the number of independent current paths equipped in the slip rings. The rated voltage refers to the maximum voltage the electric rotary connector can safely carry. It is measured in volts (V). Rated current indicates how much current the electric rotary connector can safely carry without risk of damage. It is measured in amperes (A). Maximum working speed indicates the speed at which electric rotary connectors can operate in an application.

When selecting slip rings for power or data transmission, the conditions in which they will be used are also important. Therefore, attention should also be paid to ensuring that they are adapted to the IP class and operating temperature.

Types of electric rotary connectors

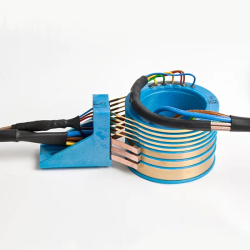

Electric rotary connectors can be divided into two types depending on the signal they are designed to transmit. The most commonly used models are those adapted for transmitting current or analog signals. They are made of metal rings and sliding contacts, usually in the form of brushes. These types of electric rotary connectors are used in industrial machines, where they supply power to rotating elements, e.g., in robots or packaging machines. Their main advantage is their simple construction and versatility in terms of the amount of current they can transmit.

In recent years, fiber-optic slip rings have also gained increasing popularity. They are designed to transmit optical signals in the form of light pulses between stationary and rotating components. These electric slip rings are equipped with an optical core made of fiber-optic material, which can be single-mode, intended for long-distance data transmission, or multi-mode, designed for short and medium-distance data transmission. Fiber-optic slip rings are characterized by high bandwidth, reaching up to several tens of Gb/s. Additionally, they are resistant to electromagnetic interference and ensure low energy loss and high signal stability, even when transmitted over long distances.

Fiber-optic electric rotary connectors are widely used in radar systems, CCTV, SSWiN devices, data transmission equipment, industrial robots, and manipulators. Their greatest advantage is that they are resistant to voltage spikes and short circuits due to the lack of current conduction.

In DACPOL, you can find both electric rotary connectors for transmitting current or analog signals, as well as fiber-optic ones. The wide selection of models allows you to choose the right solution for almost any application.