Thermally Conductive Materials

Categories

DACPOL company offers a wide range of thermal conductive materials. Our customers have known for many years that they can rely on the quality of the products we offer. We constantly strive to make the ordering and purchasing process from the enclosure department as convenient as possible for our customers, which is why we enable placing orders via the Internet and by phone.

What are the basic parameters of thermal conductive materials?

The most important parameters characterizing thermal conductive materials are:

Thermal conductivity – this is the amount of energy transferred, which depends on the material and is proportional to the cross-sectional area of the barrier, the temperature difference, the flow time, and inversely proportional to the thickness of the barrier.

Thermal impedance – this is the temperature difference between the heat-generating element and the cooling element; the impedance value depends on the pressure force as well as the size and quality of the joined surfaces.

Additional factors that should be taken into account when designing systems are:

- electrical resistance (insulation and resistance)

- mechanical strength (fire resistance and impact resistance)

- average and maximum dissipated power

- maximum operating temperature

- cooling system efficiency,

- smoothness/porosity of the cooling surface.

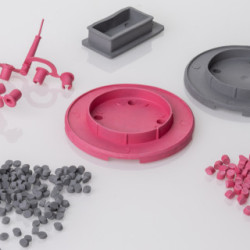

What types of thermal conductive materials do we distinguish?

Thermal conductive adhesives – these are special adhesives adapted to work in harsh conditions, which do not melt or dry out, thus retaining their properties. The use of the adhesive improves heat dissipation and additionally enhances the fastening of structural elements.

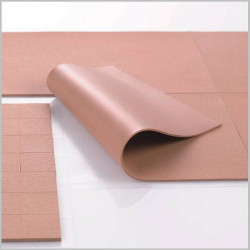

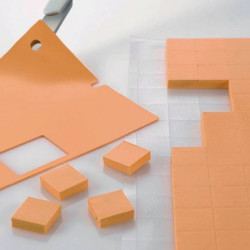

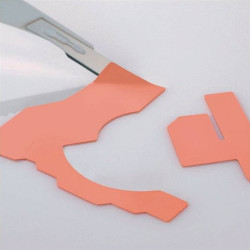

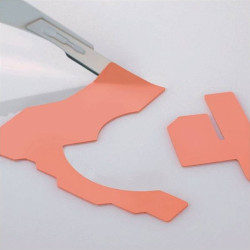

Gap fillers (GFL) – these are thermal mixtures that can be used for sealing devices as well as applying to radiators or enclosure covers. Their important advantage is ease of application, which allows securing complicated geometries. These materials are typically used to create the so-called "conduction path".

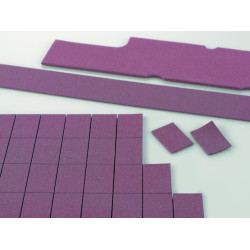

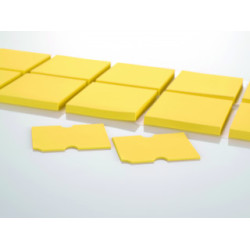

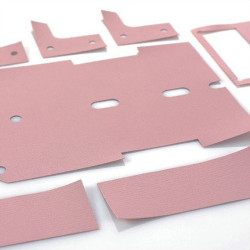

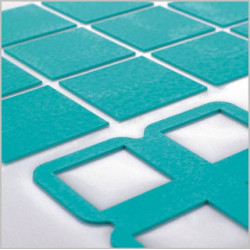

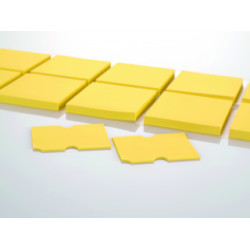

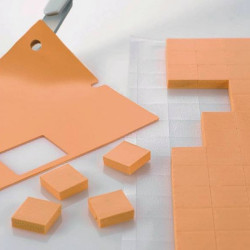

Filling materials – these are gap fillers with specific geometry and mechanical and electrical properties that allow their use in various applications. They are designed to compensate for component unevenness and are used in pressure-sensitive applications.