-

- DIN Rail Terminal Blocks

- Multipole Industrial Connectors

- Industrial Power Connectors

- Cables for sensors | LUMBERG

- Connectors for sensors

- PCB Terminals

- Battery Clamps

- Connectors | Hirschmann

- Rotary Connectors

- Electrical Connectors | SCHÜTZINGER

- Circular connectors with threaded joint | LUMBERG

- Coaxial Connectors | RADIALL

- Industrial Connectors | Han

- Power Connectors Powersafe

- Connectors and cables for charging electric vehicles

-

- Solutions for vibration control

- Control cabinets

- Accessories for Enclosures

- Articles and Technical Information

- Certifications

- Industrial keyboards, Foil Fronts, Switches and Buttons

- Thermally Conductive Materials

- Modifications / Services

- Overprints and Descriptions

- Aluminum Enclosures

- 19” Enclosures and 19" Rack-mount Enclosures

- Instrument/Desktop Metal Enclosures

- Command Enclosures and Suspension Systems

- Aluminium Profile Enclosures

- Plastic Enclosures

- Stainless Steel Enclosures

- EMC/RF/IP Protection

- Portable Cases

- Displays

- Thermal Interface Materials - Kerafol

-

- Screw lead - ALS30/31 and ALS 40/41 series

- Accessories for capacitors

- Leads for PCB and soldering - ALP/T 20 series

- Leads for PCB for latches - ALC 40 series

- ALS30 / 31 series, + 85 ° C

- ALS32 / 33 series, + 85 ° C

- ALS36 / 37 series, + 85 ° C

- PEH200 series, + 85 ° C

- ALS40 / 41 series, + 105 ° C

- ALS42 / 43 series, + 105 ° C

- PEH205 series, + 125 ° C

- ALS60 / 61 series, + 85 ° C

- ALS80 / 81 series, High CV, + 105 ° C

- ALS70 / 71 series, High CV, + 85 ° C

-

- Insulating jacket T.P.E.125˚C 16kV

- SILIGAINE 31-1 and 31-2 - 30˚C to + 450˚C

- SILIGAINE TN - protective jacket variable-diameter monofilament polyester

- SILIGAINE® 13F3 -30° C to +155 °C Class F

- SILIGAINE® 15C3 -60 °C to +250 °C Classes H and C

- SILIGAINE® GT 1 -60 °C to +300 °C

- SILIGAINE SI + 33 900 ° C - silica fiber

- SILIGAINE 21F1 -60 ° C to 280 ° C

- SILIGAINE® 13F4 -30 °C to +155 °C Class F

- SILIGAINE® 15C3-UV -60 °C to +250 °C

- SILIGAINE® 15C4.d -60 °C to +200 °C Class H

- SILIGAINE® 15C2 -60 °C to +250 °C Classes H and C

- SILIGAINE® 15C4 -60 °C to +250 °C Classes H and C

- SILIGAINE® 15C5 -60 °C to +250 °C Classes H and C

- SILIGAINE® 15C5-E Expandable -60 °C to +250 °C Classes H and C

- SILIGAINE® 15C7 UL -60 °C to +250 °C Classes H and C

- SILIGAINE® 15C10 -60 °C to +250 °C Classes H and C

- SILIGAINE GTE 1 from -60 ° C to + 250 ° C

-

- Industrial EN50155 Switches M12 | GARRETCOM

- Unmanaged Switches for DIN rail

- Industrial Switches for DIN rail with DNV Certificate

- Switches with POE function for DIN rail

- Industrial EN50155 Switches M12 | LANTECH

- Industrial Gigabit Switches for DIN rail

- Unmanaged 3 ports fiber optic switches for DIN rail

- Unmanaged 5 ports fiber optic switches for DIN rail

- Unmanaged 8 ports fiber optic switches for DIN rail

- Unmanaged Panel Switch ADAM

- Managed Switches for DIN rail

- Switches dedicated to the railways in accordance with EN50155

-

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- Galvanized and Stainless Steel Cylindrical Braids

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

Discover our products related to electric traction

We are involved in both tram and railway traction. Therefore, we offer a wide range of products for various power levels, currents, and applications. We have a broad assortment of components such as: thyristors, diodes, railway cables, and supercapacitors.

What is electric traction?

Electric traction refers to the propulsion of mechanical vehicles powered by electric motors. Typically, traction vehicles (electric locomotives, rail and tram motor cars, trolleybuses) use DC motors powered by electricity delivered via an overhead contact line running along the route, transferred using a pantograph sliding on the wire. Compared to other types of traction (steam or diesel), electric traction has better operational characteristics:

- it is cheaper,

- the vehicles used are lighter,

- it enables large displacements,

- it has a short braking time.

A disadvantage of electric traction is the high cost of route electrification.

How is the traction network powered?

The power supply of electric traction, regardless of the type of current or voltage level, is characterized by an electrical circuit. This circuit is built from specific elements, each playing a role in the power system. These elements include:

- Traction substation – its purpose is to convert current and voltage into levels suitable for powering traction vehicles.

- Power cable – responsible for transmitting energy from the substation to the traction network.

- Overhead line – composed of the contact wire and a catenary wire that supports it. The contact wire connects with the pantograph. The function of the overhead line is to deliver energy to the vehicle through the pantograph mounted on the locomotive.

- Traction vehicle – converts electrical energy into mechanical, thermal, and light energy.

- Rails – referred to as the return network and carry a negative potential. They are connected with transverse and longitudinal connectors.

- Return cable – its task is to connect the rails to the traction substation.

Our product range includes the following:

- High-frequency non-inductive shunts

- LEM current and voltage transducers

- Fans

- Fuses

- Connectors

- Diodes

- Thyristors

- Electrically isolated modules

- Rectifier bridges

- Pulse transformers for triggering thyristors and triacs

- Heatsinks

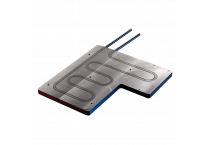

- Kerafol thermal interface materials

- Varistors

- Thermal protection

- Cables for special applications

- Batteries, chargers, backup power supplies, and converters

- Cable terminals

- Industrial enclosures, keyboards, EMC/RFI protection

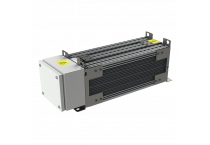

- Braking resistors

- Electrolytic capacitors

- Interference suppression and pulse capacitors

- Icel film capacitors

- Power capacitors

- Insulating sleeves

- Supercapacitors

- Push buttons and switches

- Industrial ETHERNET switches

- Conduits, pipes

- Braided sleeving

- Railway cables

The electric traction department's offer enables the electrification of new lines and the potential modernization of existing ones. The products we offer come from leading manufacturers, ensuring high quality. We make every effort to ensure the ordering process is as convenient as possible for our customers, which is why we offer the option to order by phone and online.