Debes estar logueado

Category

Las fotos son solo para fines informativos. Ver especificaciones de producto

please use latin characters

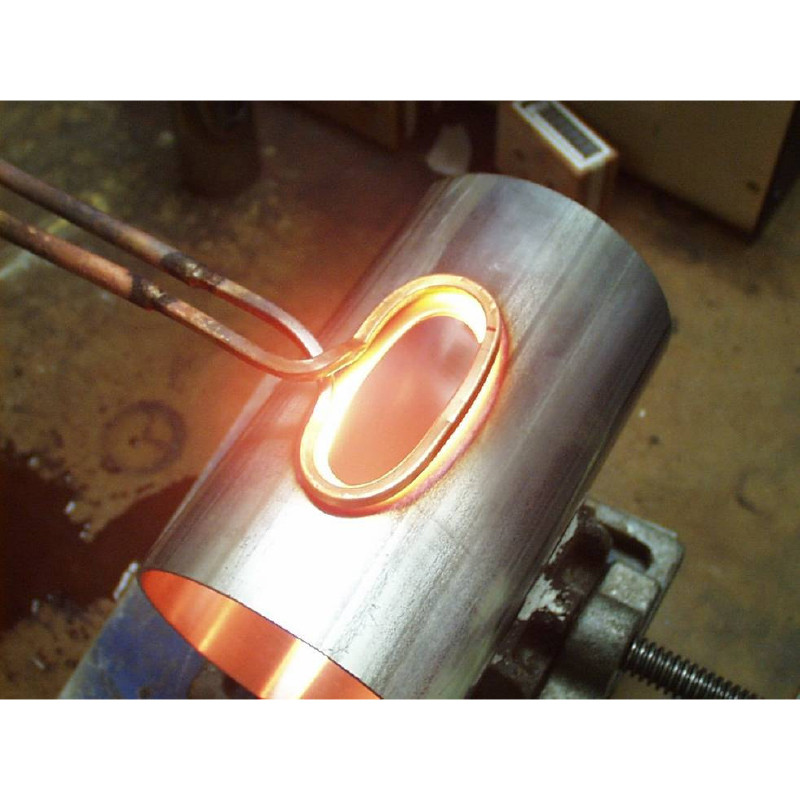

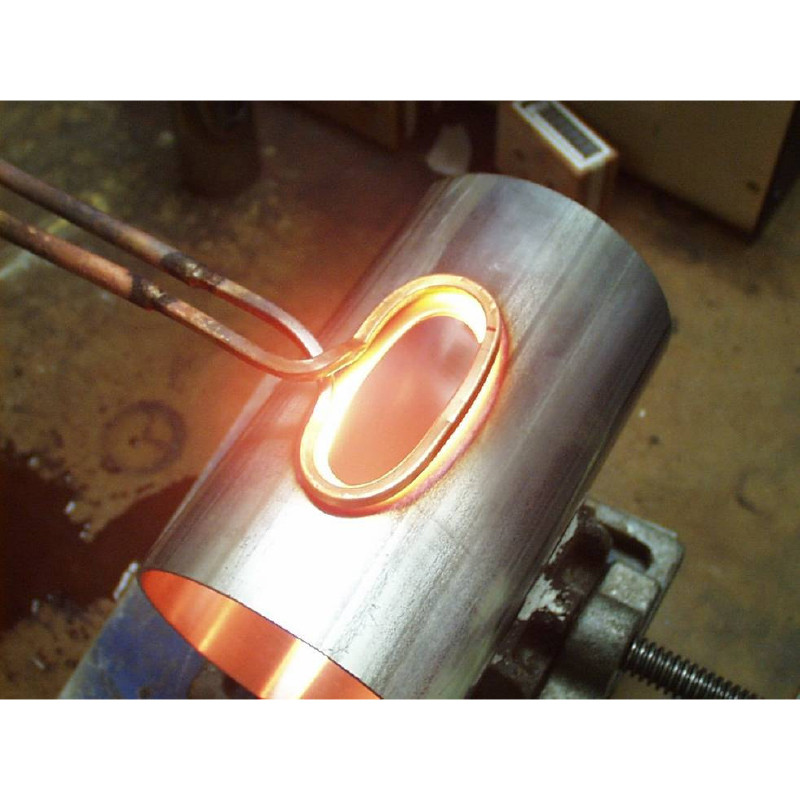

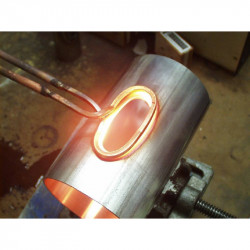

Objective: To anneal a ¼” area around an oval cutout on a stainless steel tube prior to extrusion.

Frequency: 300 kHz

Material: .75” (19mm), 1.5” (38.1mm) and 4” (101.6mm) diameter steel tubes

Temperature: 1900 °F (1038 °C)

A single turn helical coil is used on the 4” (101.6mm) diameter tubes and a two turn helical coil is used on the smaller diameters. The coil is placed over the oval cutout and power is supplied for 15 seconds to anneal a 0.25" (6.35mm) diameter around the cutout.

¿Estás interesado en este producto? ¿Necesita información adicional o precios individuales?

Usted debe estar conectado

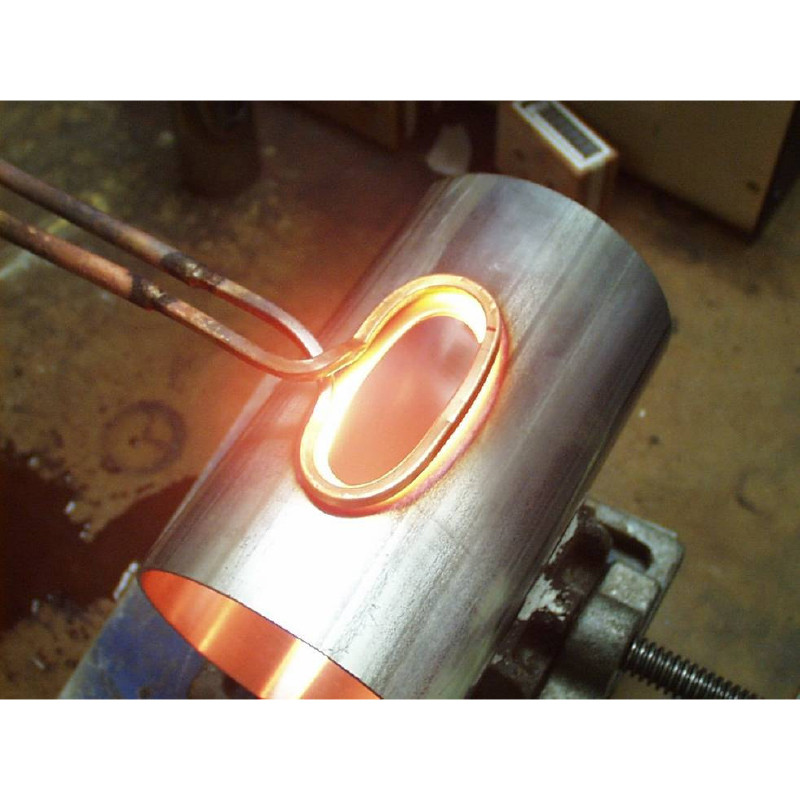

Objective: To anneal a ¼” area around an oval cutout on a stainless steel tube prior to extrusion.

Frequency: 300 kHz

Material: .75” (19mm), 1.5” (38.1mm) and 4” (101.6mm) diameter steel tubes

Temperature: 1900 °F (1038 °C)

A single turn helical coil is used on the 4” (101.6mm) diameter tubes and a two turn helical coil is used on the smaller diameters. The coil is placed over the oval cutout and power is supplied for 15 seconds to anneal a 0.25" (6.35mm) diameter around the cutout.

Su agradecimiento a la reseña no pudo ser enviado

Reportar comentario

Reporte enviado

Su reporte no pudo ser enviado

Escriba su propia reseña

Reseña enviada

Su reseña no pudo ser enviada