Debes estar logueado

Category

Las fotos son solo para fines informativos. Ver especificaciones de producto

please use latin characters

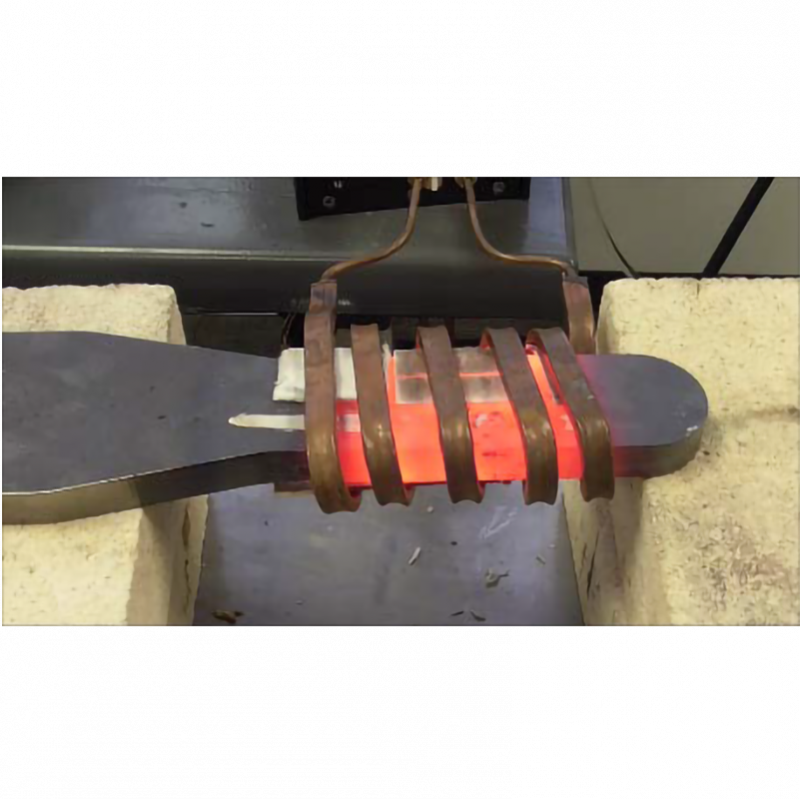

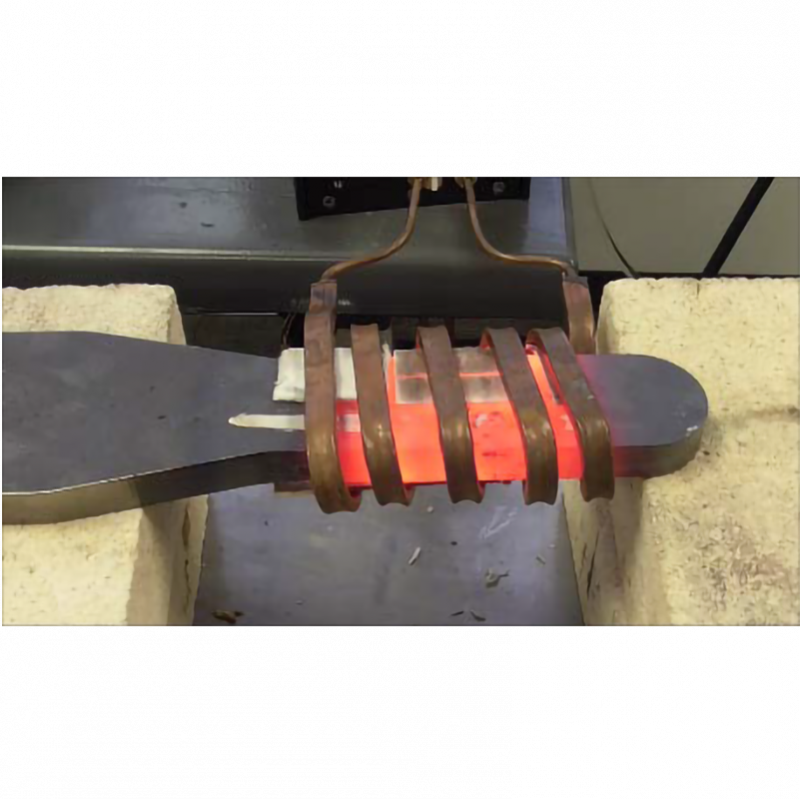

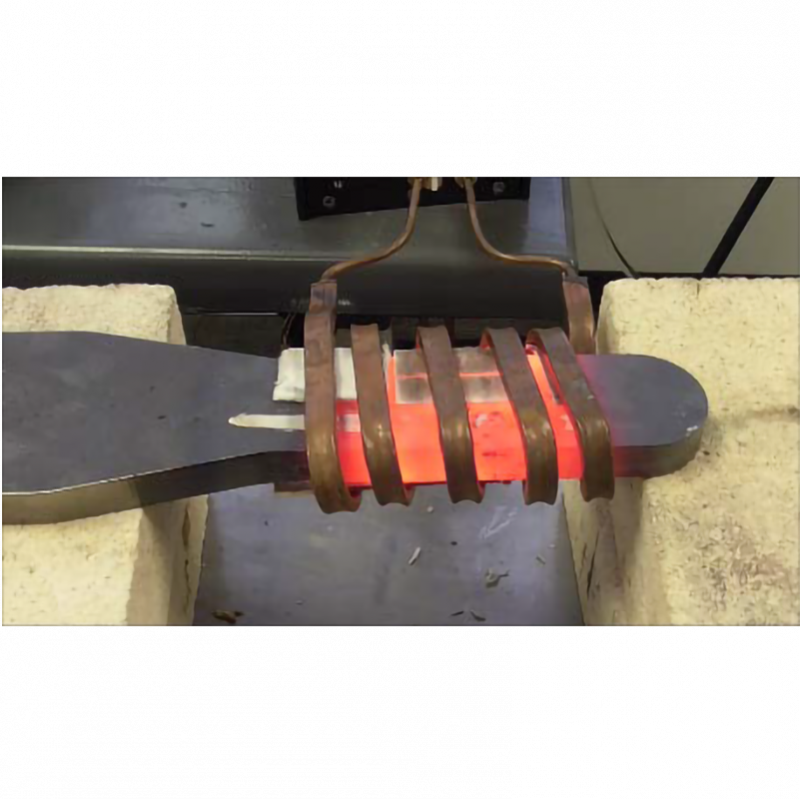

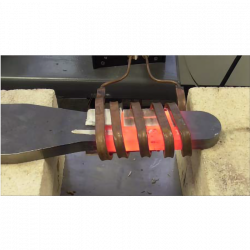

Objective: To heat a magnetic steel part for a forming application; the client had been using a torch for the application.

Frequency: 125 kHz

Material: Magnetic steel part

Temperature: 1700 °F (927 °C)

Temperature indicating paint was applied to the part to easily identify when it achieved temperature, and then the induction power was turned on. It took about three minutes for the part to reach 1700 °F (927 °C) at 10 kW and two minutes and twenty seconds with 15 kW for this through-Curie heating application.

¿Estás interesado en este producto? ¿Necesita información adicional o precios individuales?

Usted debe estar conectado

Objective: To heat a magnetic steel part for a forming application; the client had been using a torch for the application.

Frequency: 125 kHz

Material: Magnetic steel part

Temperature: 1700 °F (927 °C)

Temperature indicating paint was applied to the part to easily identify when it achieved temperature, and then the induction power was turned on. It took about three minutes for the part to reach 1700 °F (927 °C) at 10 kW and two minutes and twenty seconds with 15 kW for this through-Curie heating application.

Su agradecimiento a la reseña no pudo ser enviado

Reportar comentario

Reporte enviado

Su reporte no pudo ser enviado

Escriba su propia reseña

Reseña enviada

Su reseña no pudo ser enviada