Debes estar logueado

Category

Las fotos son solo para fines informativos. Ver especificaciones de producto

please use latin characters

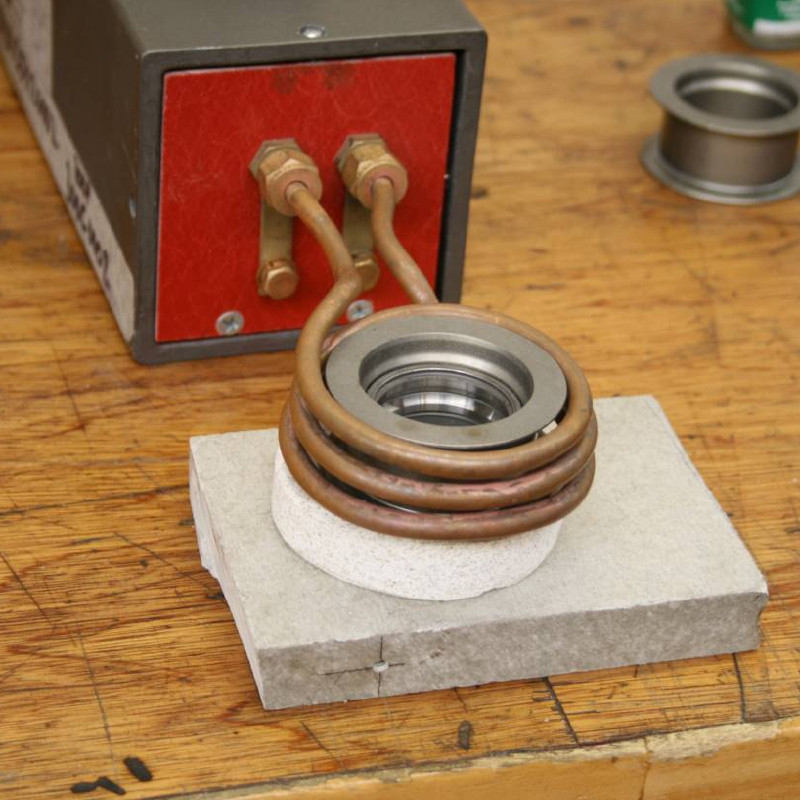

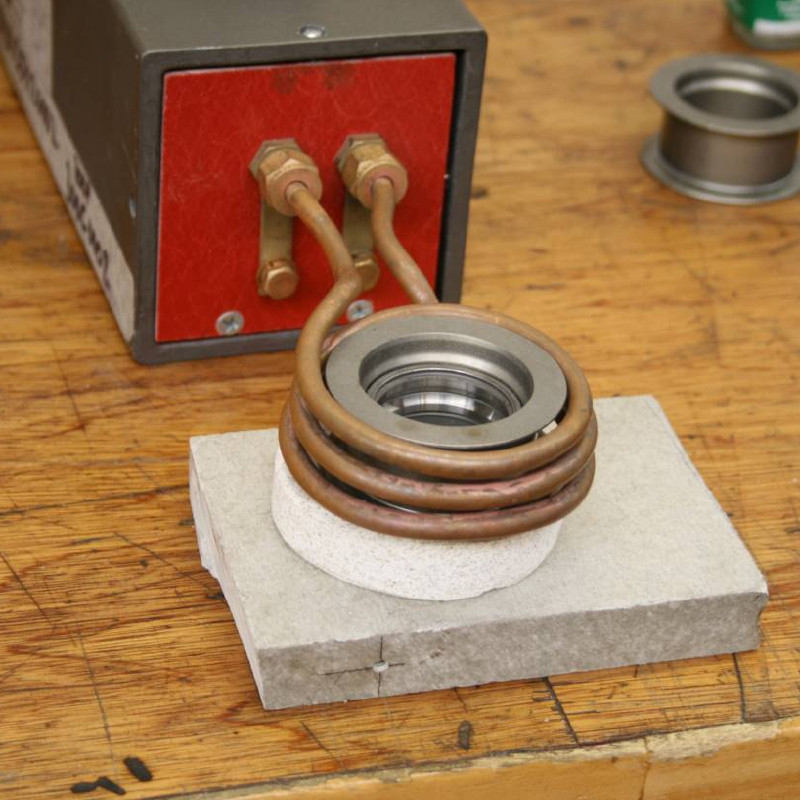

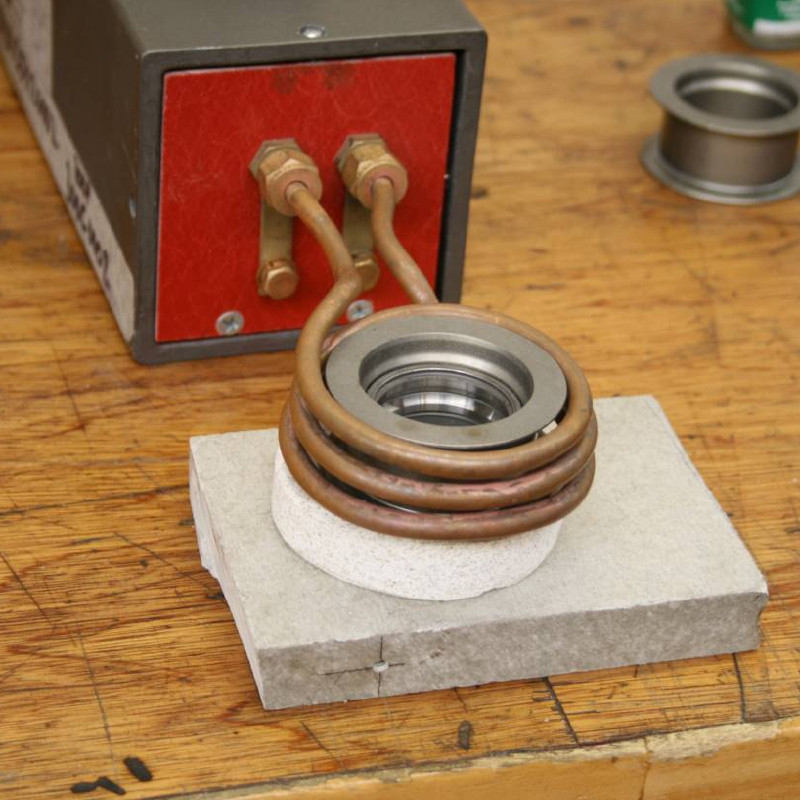

Objective: To heat aluminum pulley for insertion of an inner bearing for the automotive industry.

Frequency: 283 kHz

Material: Aluminum pulley 2.3” (60mm) OD x 1.6” (40mm) ID x 1” (27mm) high and inner bearing 0.7” (17.8mm) high x 1.6” (40mm) dia.

Temperature: 464 °F (240 °C)

A three turn helical coil is used to heat the aluminum pulley. The pulley is heated to 464 ºF (240 ºC) in 20 seconds to expand the inner diameter and then the inner bearing is inserted to form the completed part.

¿Estás interesado en este producto? ¿Necesita información adicional o precios individuales?

Usted debe estar conectado

Objective: To heat aluminum pulley for insertion of an inner bearing for the automotive industry.

Frequency: 283 kHz

Material: Aluminum pulley 2.3” (60mm) OD x 1.6” (40mm) ID x 1” (27mm) high and inner bearing 0.7” (17.8mm) high x 1.6” (40mm) dia.

Temperature: 464 °F (240 °C)

A three turn helical coil is used to heat the aluminum pulley. The pulley is heated to 464 ºF (240 ºC) in 20 seconds to expand the inner diameter and then the inner bearing is inserted to form the completed part.

Su agradecimiento a la reseña no pudo ser enviado

Reportar comentario

Reporte enviado

Su reporte no pudo ser enviado

Escriba su propia reseña

Reseña enviada

Su reseña no pudo ser enviada