Debes estar logueado

Category

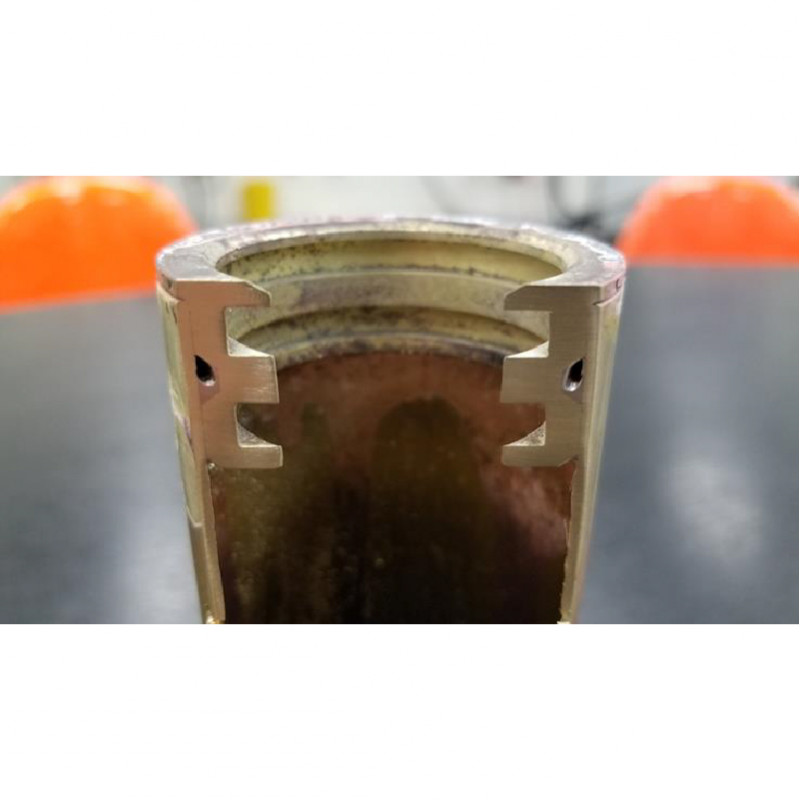

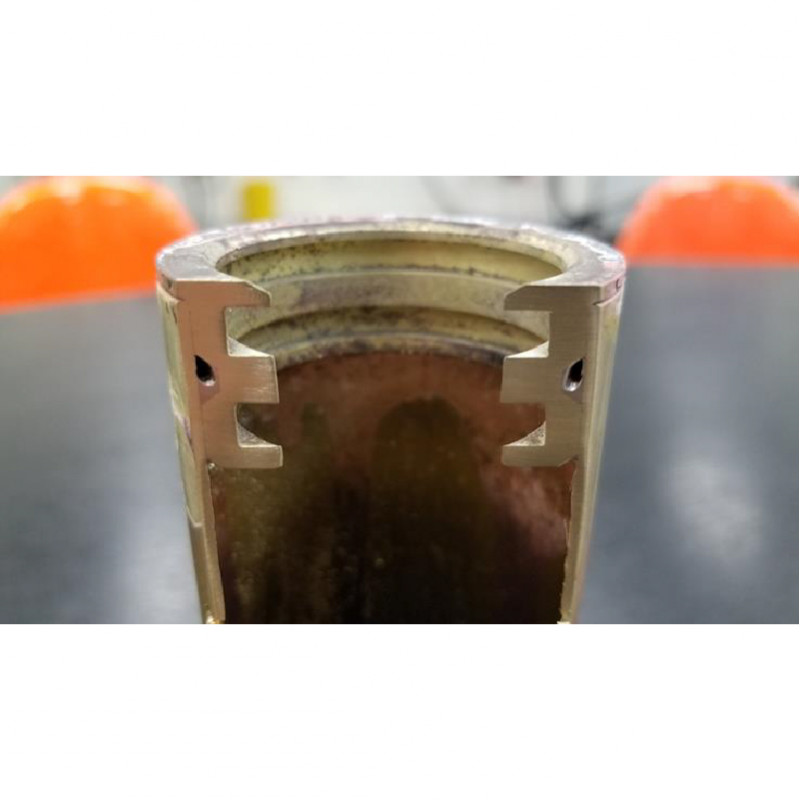

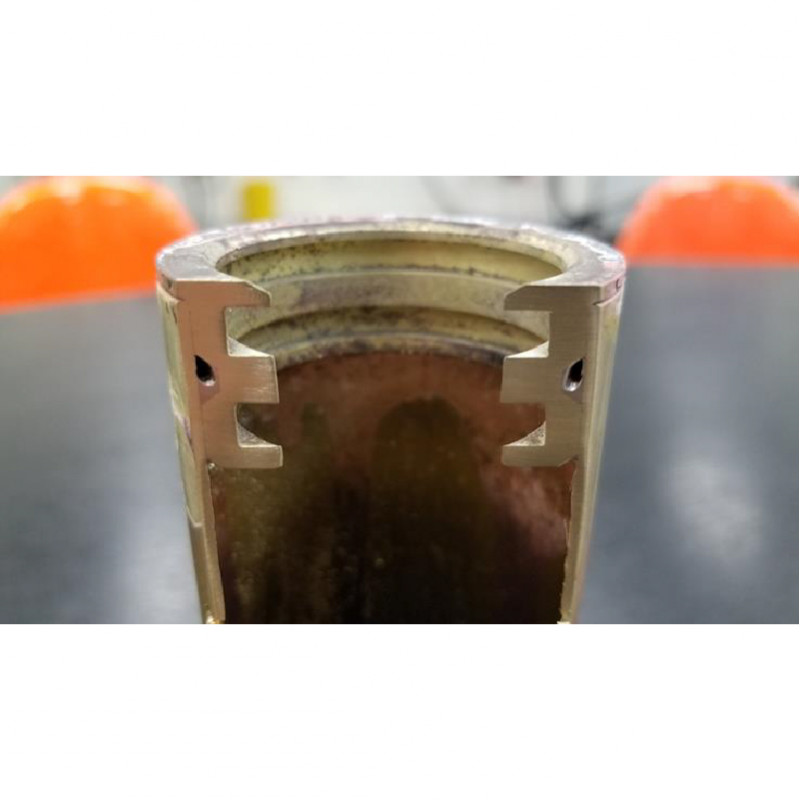

Las fotos son solo para fines informativos. Ver especificaciones de producto

please use latin characters

Objective: To heat brass assemblies for a brazing application; the client had been using a torch and is a manufacturer of sink products.

Frequency: 316 kHz

Material: Brass assemblies (2”/51 mm OD)

Temperature: 1425 °F (773 °C)

A custom-designed single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. It took two minutes to heat the 2”/51 mm OD brass assembly to temperature.

¿Estás interesado en este producto? ¿Necesita información adicional o precios individuales?

Usted debe estar conectado

Objective: To heat brass assemblies for a brazing application; the client had been using a torch and is a manufacturer of sink products.

Frequency: 316 kHz

Material: Brass assemblies (2”/51 mm OD)

Temperature: 1425 °F (773 °C)

A custom-designed single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. It took two minutes to heat the 2”/51 mm OD brass assembly to temperature.

Su agradecimiento a la reseña no pudo ser enviado

Reportar comentario

Reporte enviado

Su reporte no pudo ser enviado

Escriba su propia reseña

Reseña enviada

Su reseña no pudo ser enviada