Debes estar logueado

Category

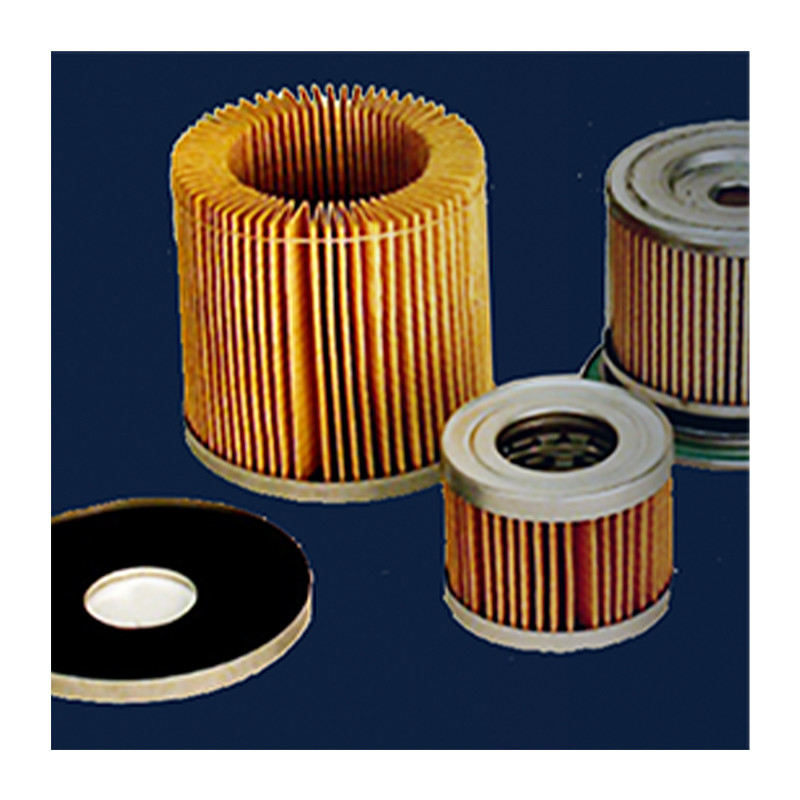

Las fotos son solo para fines informativos. Ver especificaciones de producto

please use latin characters

Curing involves any process where heat is used to catalyze or initiate chemical and molecular level structural changes in a polymeric materials such as epoxies, phenolics, polyesters and silicones. These materials are applied in many ways to various products for bonding, protective coating, sealing, insulation and other uses.

Jell coating is a partial-curing process whereby a liquid compound is heated (in this case plastisol) enough so it doesn’t run when it is flipped over.

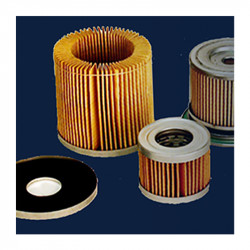

Curing plastisol oil filter seals with induction is a reliable, repeatable, non-contact and energy-efficient process, delivering quality results in a minimal amount of time. Improved temperature ramping cycles can be achieved with computer control of the solid state power supply. Although induction heating is normally used with metals or other conductive materials, plastics and other non-conductive materials can often be heated very effectively by using a conductive metal susceptor to transfer the heat. Typical RF power supplies for curing applications range from 1 to 5 kW, depending on the parts and application requirement

¿Estás interesado en este producto? ¿Necesita información adicional o precios individuales?

Usted debe estar conectado

Curing involves any process where heat is used to catalyze or initiate chemical and molecular level structural changes in a polymeric materials such as epoxies, phenolics, polyesters and silicones. These materials are applied in many ways to various products for bonding, protective coating, sealing, insulation and other uses.

Jell coating is a partial-curing process whereby a liquid compound is heated (in this case plastisol) enough so it doesn’t run when it is flipped over.

Curing plastisol oil filter seals with induction is a reliable, repeatable, non-contact and energy-efficient process, delivering quality results in a minimal amount of time. Improved temperature ramping cycles can be achieved with computer control of the solid state power supply. Although induction heating is normally used with metals or other conductive materials, plastics and other non-conductive materials can often be heated very effectively by using a conductive metal susceptor to transfer the heat. Typical RF power supplies for curing applications range from 1 to 5 kW, depending on the parts and application requirement

Su agradecimiento a la reseña no pudo ser enviado

Reportar comentario

Reporte enviado

Su reporte no pudo ser enviado

Escriba su propia reseña

Reseña enviada

Su reseña no pudo ser enviada