Debes estar logueado

-

moreX

-

Componentes

-

-

Category

-

Semiconductores

- Diodos

- Tiristores

-

Módulos con aislamiento eléctrico

- Módulos con aislamiento eléctrico | VISHAY (IR)

- Módulos con aislamiento eléctrico | INFINEON (EUPEC)

- Módulos con aislamiento eléctrico | Semikron

- Módulos con aislamiento eléctrico | POWEREX

- Módulos con aislamiento eléctrico | IXYS

- Módulos con aislamiento eléctrico | POSEICO

- Módulos con aislamiento eléctrico | ABB

- Módulos con aislamiento eléctrico | TECHSEM

- Go to the subcategory

- Rectificadores de puente

-

Transistores

- Transistores | GeneSiC

- Módulos SiC MOSFET | Mitsubishi

- Módulos SiC MOSFET | STARPOWER

- Módulos ABB SiC MOSFET

- Módulos IGBT | MITSUBISHI

- Módulos de transistores | MITSUBISHI

- Módulos MOSFET | MITSUBISHI

- Módulos de transistores | ABB

- Módulos IGBT | POWEREX

- Módulos IGBT | INFINEON (EUPEC)

- Elementos semiconductores de carburo de silicio (SiC)

- Go to the subcategory

- Controladores de puerta

- Bloques de energía

- Go to the subcategory

- Convertidores de corriente y tensión LEM

-

Componentes pasivos (condensadores, resistencias, fusibles, filtros)

- Resistencias

-

Fusibles

- Fusibles miniatura para circuitos electrónicos, serie ABC y AGC

- Fusibles tubulares de acción rápida

- Eslabones fusibles de retardo de tiempo con características GL / GG y AM

- Eslabones fusibles ultrarrápidos

- Fusibles de acción rápida (estándar británico y estadounidense)

- Fusibles de acción rápida (estándar europeo)

- Fusibles de tracción

- Eslabones fusibles de alto voltaje

- Go to the subcategory

-

Condensadores

- Condensadores de motor

- Condensadores electrolíticos

- Condensadores de película

- Condensadores de potencia

- Condensadores para circuitos de CC

- Condensadores de corrección del factor de potencia

- Condensadores de alto voltaje

- Condensadores de calentamiento por inducción

- Condensadores de almacenamiento de energía y pulsos

- Condensadores de ENLACE CC

- Condensadores para circuitos AC/DC

- Go to the subcategory

- Filtros EMI

- Supercondensadores

-

Protección contra sobretensiones

- Protección contra sobretensiones para aplicaciones coaxiales

- Protección contra sobretensiones para sistemas de videovigilancia

- Protección contra sobretensiones para cableado de potencia

- Pararrayos para LED

- Descargadores de sobretensiones para energía fotovoltaica

- Protección del sistema de pesaje

- Protección contra sobretensiones para Fieldbus

- Go to the subcategory

- Filtros para detección de emisiones TEMPEST

- Go to the subcategory

-

Relés y contactores

- Teoría de relés y contactores

- Relés semiconductores de CA trifásicos

- Relés semiconductores de CA trifásicos

- Reguladores, controles y accesorios

- Arranques suaves y contactores de inversión

- Relés electromecánicos

- Contactores

- Interruptores giratorios

-

Relés semiconductores de CA monofásicos

- Relés semiconductores CA monofásicos, serie 1 | D2425 | D2450

- Relés semiconductores CA monofásicos, series CWA y CWD

- Relés semiconductores CA monofásicos de las series CMRA y CMRD

- Relés semiconductores de CA monofásicos, serie PS

- Relés semiconductores de CA dobles y cuádruples, serie D24 D, TD24 Q, H12D48 D

- Relés de estado sólido monofásicos, serie gn

- Relés semiconductores de ca monofásicos, serie ckr

- Relés AC monofásicos SERIE ERDA Y ERAA para carril DIN

- Relés AC monofásicos para corriente 150A

- Relés dobles de estado sólido integrados con disipador de calor para carril DIN

- Go to the subcategory

- Relés semiconductores CA monofásicos para PCB

- Relés de interfaz

- Go to the subcategory

- Núcleos y otros componentes inductivos

- Radiadores, varistores, protecciones térmicas

- Aficionados

- Aire Acondicionado, Accesorios para Armarios Eléctricos, Neveras

-

Baterías, cargadores, fuentes de alimentación de búfer e inversores

- Baterías, cargadores - descripción teórica

- Baterías de iones de litio. Baterías personalizadas. Sistema de gestión de batería (BMS)

- Pilas

- Cargadores de baterías y accesorios

- Fuente de alimentación de respaldo de UPS y fuentes de alimentación de búfer

- Convertidores y accesorios para fotovoltaica

- Almacen de energia

- Celdas de combustible

- Baterías de iones de litio

- Go to the subcategory

- Automaticas

-

Cables, alambres Litz, conductos, conexiones flexibles

- alambres

- cables Litz

-

Cables para aplicaciones especiales

- Los cables de extensión y compensación

- Cables para termopares

- Los cables de conexión a PT czyjnków

- Multicore cables temp. -60 ° C a + 1400 ° C

- cables de media tensión SILICOUL

- ignición alambres

- Los cables calefactores

- temp núcleo único. -60 ° C a + 450 ° C

- conductores de trenes

- El calentamiento de los cables en el Ex

- Go to the subcategory

- camisas

-

trenzas

- trenzas planas

- trenzas ronda

- trenza muy flexible - plana

- trenza muy flexible - Ronda

- Copper cilíndrico trenzado

- Copper protector de la trenza y cilíndrica

- cintas de conexión flexibles

- Trenzas cilíndrico galvanizado y acero inoxidable

- Aislamiento de PVC trenzas de cobre - Temperatura 85 ° C

- aluminio trenzado plano

- Kit de conexión - trenzas y tubos

- Go to the subcategory

- Accesorios para la tracción

- Terminales de cable

- barras flexibles aisladas

- carril flexible multicapa

- sistemas de gestión de cables

- Go to the subcategory

- View all categories

-

Semiconductores

-

-

- Suppliers

-

Applications

- Accionamientos de CA y CC (inversores)

- Automatización HVAC

- Automatización industrial

- Automatización industrial

- Calentamiento por inducción

- Componentes para atmósferas potencialmente explosivas (EX)

- Dispositivos de protección industrial

- Energy bank

- Equipos para Armarios de Distribución, Control y Telecomunicaciones

- Fuentes de alimentación (UPS) y sistemas rectificadores

- Impresión

- Máquinas de soldar y máquinas de soldar

- Máquinas herramientas CNC

- Máquinas para secar y procesar madera

- Máquinas para termoformado de plásticos

- Medición y regulación de temperatura

- Medición y regulación de temperatura

- Minería, metalurgia y fundación

- Motores y transformadores

- Tracción de tranvía y ferrocarril

-

Instalación

-

-

Inductores

-

-

Dispositivos de inducción

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Servicio

-

- Contact

- Zobacz wszystkie kategorie

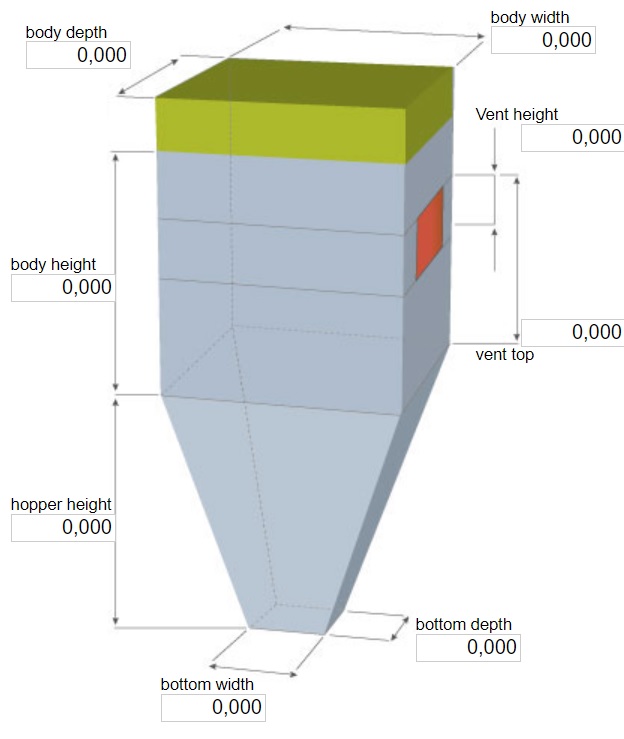

Explosion venting in hazardous areas

Actions taken to eliminate or reduce the risk of explosion should lead to the complete removal of the risk of explosion.

In reality, however, it often happens that it is not possible to get rid of the explosive atmosphere, because these are the conditions of the processes being carried out or it would require huge financial outlays. Similarly, it also happens that the elimination of the risk of effective ignition sources is impossible to achieve. In that case, taking into account the the principle of integrated safety included in the ATEX directive - you can use protective systems that represent the third, last level of protection and whose task is to signal a threat, immediately stop an emerging explosion or limit its range. One of such solutions are explosion relief devices, protecting various types of tanks against the effects of an explosion in the internal space.

The basic components of the explosion relief system are relief surfaces made in the walls in the form of flaps and ensuring that the maximum explosion pressure inside the tank does not exceed its pressure resistance. According to the standards describing this issue, i.e.:

- PN-EN 14797 – requirements for relief devices,

- PN-EN 14491 – protection against dust explosion,

- PN-EN 14994 – gas explosion protection,

in the design, calculations are used for various pressures taken into account when selecting the appropriate dampers. Generally, it is assumed that an unloaded explosion is treated with maximum pressure (p_max), an explosion relieved with reduced pressure (p_red), and the moment of activation of protections - i.e. opening of dampers - takes place at the moment of occurrence of static pressure (p_stat) within the given tolerance range. It is assumed that the fixed parts of the devices should not be damaged, and during the unloading process, there should be no scattering of fragments of the unloading elements, as this could cause additional hazards. Some manufacturers also offer built-in back pressure protection.

Among the parameters defining the unloading properties, in addition to the static opening pressure and its tolerance, there is also the maximum value of Kg/Kst - i.e. the ratio of the gas constant to the dust constant - and the maximum reduced pressure provided by the manufacturer. The minimum efficiency of unloading and certain design requirements affecting the preservation of protective/process properties are also important, such as the accumulation of substances outside (snow, ice, etc.) and inside (product), resistance to physical and chemical conditions, hygienic requirements, the issue of seals and detection detectors operation or thermal insulation. From the mechanical point of view, it is much easier to implement ventilation flaps at the planning stage of building a new e.g. grain silo than when rebuilding an existing one.

Most of the work related to the selection of protective devices is performed by the manufacturer of the given solution, but thanks to the Ex trainings we conduct, it is possible to become familiar with the technology and principle of operation of explosion relief systems and other systems that can be used in the presence of fuel-air mixtures (regardless of whether the fuel is combustible gas or dust). Each security method has its purpose, specificity, and at the same time has advantages and disadvantages that should be taken into account when deciding on a particular device. In the case of dampers, it is worth remembering that they do not protect against the explosion itself, and even more so against the occurrence of an explosive atmosphere or sources of ignition. They only limit the pressure of the explosion in the protected space, i.e. by definition of relief, it is assumed that an explosion must occur for the system to work. Another thing is the fact that the protective system alone is not enough to protect the installation against explosion. In this way, it is possible to "secure" the facility or mitigate the effects of a failure that generates uncontrolled release of energy and/or heat, but the approach to process safety should be holistic, reaching into various areas of the plant's operation (risk analysis and assessment, instructions, employee training, ATEX where necessary, protective systems, etc.) and thus treat the risk of explosion as a whole.

Features:

- suitable for both dust and gas explosions,

- 100% efficiency,

- usable with underpressure and overpressure,

- simple and fast mounting,

- smooth interior surface eliminates 'dead corners'.

- also available with thermal insulation in high temperature version.

Publicaciones relacionadas

Ochrona przeciwwybuchowa - Podział na strefy zagrożone wybuchem

Ochrona przeciwwybuchowa - Podział na strefy zagrożone wybuchem

Wybuch i strefa zagrożona wybuchem.

Wybuch i strefa zagrożona wybuchem.

Measures (preventive) of explosion protection

Measures (preventive) of explosion protection

Deja un comentario