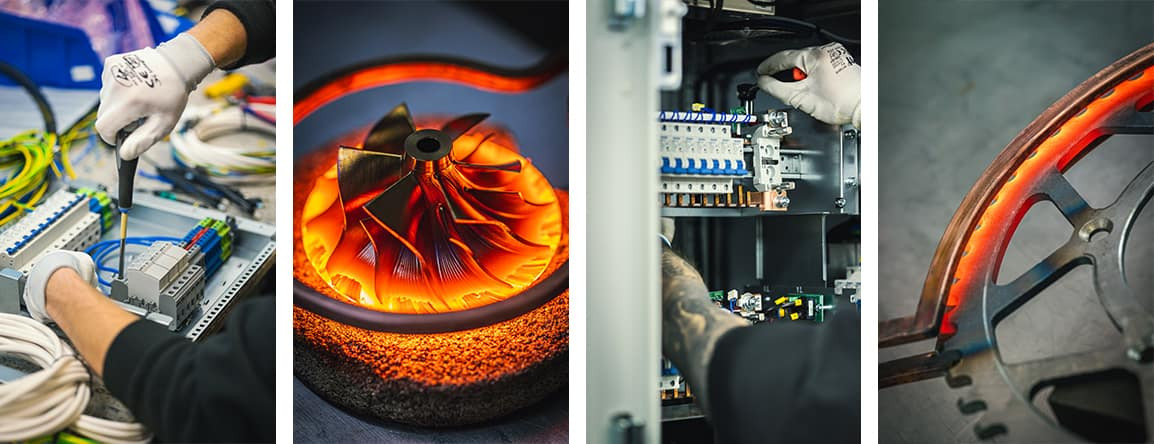

El artículo presenta el camino desde las bases de la electrónica hasta la construcción de dispositivos más avanzados, mostrando el papel de los kits educativos, los componentes electrónicos y los módulos de potencia. Explica cómo los kits de montaje desarrollan habilidades prácticas y cómo fuentes de alimentación, controladores y elementos de potencia bien seleccionados permiten crear tanto proyectos de afición como soluciones cercanas a la electrónica industrial.

Componentes para la electrónica de potencia - automatización industrial - electrónica - ingeniería de potencia - ingeniería eléctrica

Proveedoras

Ver todos los proveedoresCategorías de Producto

Ver todas las categoriasÚltimas entradas del blog

-

Iluminación industrial LED vs tradicional – diferencias, beneficios y desafíos para las naves de producción modernasRead more

El artículo presenta las principales diferencias entre la iluminación industrial LED y las fuentes de luz tradicionales, como las lámparas de sodio o de mercurio. Analiza los parámetros clave que influyen en el trabajo en las naves de producción: eficiencia energética, vida útil, calidad de la luz, costes de operación y aspectos ecológicos. Destaca el creciente papel de la tecnología LED en la modernización de instalaciones industriales y señala los beneficios de su uso, así como las situaciones en las que las lámparas tradicionales todavía pueden emplearse. El artículo muestra por qué los LED se están convirtiendo en el estándar en las plantas de producción y almacenes modernos.

-

Transformación industrial y energética – cómo la electrónica de potencia impulsa una nueva era tecnológicaRead more

Este artículo muestra cómo la electrónica de potencia se ha convertido en un motor clave de la transformación energética e industrial moderna. Describe su papel en la integración de fuentes de energía renovable, almacenamiento y conversión de energía, estabilización de la red y automatización de procesos industriales. El texto presenta tanto las aplicaciones actuales de la electrónica de potencia como sus perspectivas de desarrollo, destacando su importancia para el desarrollo sostenible, la digitalización de la infraestructura y la implementación de la Industria 4.0.

![Componentes para áreas peligrosas y atmósferas explosivas [Ex]](https://www.dacpol.eu/c/6823-catsmal_default/componentes-para-areas-peligrosas-y-atmosferas-explosivas-ex-.jpg)