Debes estar logueado

-

WróćX

-

Componentes

-

-

Category

-

Semiconductores

- Diodos

- Tiristores

-

Módulos con aislamiento eléctrico

- Módulos con aislamiento eléctrico | VISHAY (IR)

- Módulos con aislamiento eléctrico | INFINEON (EUPEC)

- Módulos con aislamiento eléctrico | Semikron

- Módulos con aislamiento eléctrico | POWEREX

- Módulos con aislamiento eléctrico | IXYS

- Módulos con aislamiento eléctrico | POSEICO

- Módulos con aislamiento eléctrico | ABB

- Módulos con aislamiento eléctrico | TECHSEM

- Przejdź do podkategorii

- Rectificadores de puente

-

Transistores

- Transistores | GeneSiC

- Módulos SiC MOSFET | Mitsubishi

- Módulos SiC MOSFET | STARPOWER

- Módulos ABB SiC MOSFET

- Módulos IGBT | MITSUBISHI

- Módulos de transistores | MITSUBISHI

- Módulos MOSFET | MITSUBISHI

- Módulos de transistores | ABB

- Módulos IGBT | POWEREX

- Módulos IGBT | INFINEON (EUPEC)

- Elementos semiconductores de carburo de silicio (SiC)

- Przejdź do podkategorii

- Controladores de puerta

- Bloques de energía

- Przejdź do podkategorii

- Convertidores de corriente y tensión LEM

-

Componentes pasivos (condensadores, resistencias, fusibles, filtros)

- Resistencias

-

Fusibles

- Fusibles miniatura para circuitos electrónicos, serie ABC y AGC

- Fusibles tubulares de acción rápida

- Eslabones fusibles de retardo de tiempo con características GL / GG y AM

- Eslabones fusibles ultrarrápidos

- Fusibles de acción rápida (estándar británico y estadounidense)

- Fusibles de acción rápida (estándar europeo)

- Fusibles de tracción

- Eslabones fusibles de alto voltaje

- Przejdź do podkategorii

-

Condensadores

- Condensadores de motor

- Condensadores electrolíticos

- Condensadores de película

- Condensadores de potencia

- Condensadores para circuitos de CC

- Condensadores de corrección del factor de potencia

- Condensadores de alto voltaje

- Condensadores de calentamiento por inducción

- Condensadores de almacenamiento de energía y pulsos

- Condensadores de ENLACE CC

- Condensadores para circuitos AC/DC

- Przejdź do podkategorii

- Filtros EMI

- Supercondensadores

- Protección contra sobretensiones

- Filtros para detección de emisiones TEMPEST

- Pararrayos

- Przejdź do podkategorii

-

Relés y contactores

- Teoría de relés y contactores

- Relés semiconductores de CA trifásicos

- Relés semiconductores de CA trifásicos

- Reguladores, controles y accesorios

- Arranques suaves y contactores de inversión

- Relés electromecánicos

- Contactores

- Interruptores giratorios

-

Relés semiconductores de CA monofásicos

- Relés semiconductores CA monofásicos, serie 1 | D2425 | D2450

- Relés semiconductores CA monofásicos, series CWA y CWD

- Relés semiconductores CA monofásicos de las series CMRA y CMRD

- Relés semiconductores de CA monofásicos, serie PS

- Relés semiconductores de CA dobles y cuádruples, serie D24 D, TD24 Q, H12D48 D

- Relés de estado sólido monofásicos, serie gn

- Relés semiconductores de ca monofásicos, serie ckr

- Relés AC monofásicos SERIE ERDA Y ERAA para carril DIN

- Relés AC monofásicos para corriente 150A

- Relés dobles de estado sólido integrados con disipador de calor para carril DIN

- Przejdź do podkategorii

- Relés semiconductores CA monofásicos para PCB

- Relés de interfaz

- Przejdź do podkategorii

- Núcleos y otros componentes inductivos

- Radiadores, varistores, protecciones térmicas

- Aficionados

- Aire Acondicionado, Accesorios para Armarios Eléctricos, Neveras

-

Baterías, cargadores, fuentes de alimentación de búfer e inversores

- Baterías, cargadores - descripción teórica

- Baterías de iones de litio. Baterías personalizadas. Sistema de gestión de batería (BMS)

- Pilas

- Cargadores de baterías y accesorios

- Fuente de alimentación de respaldo de UPS y fuentes de alimentación de búfer

- Convertidores y accesorios para fotovoltaica

- Almacen de energia

- Celdas de combustible

- Baterías de iones de litio

- Przejdź do podkategorii

-

Automaticas

- Elevadores Spiralift

- Piezas para drones Futaba

- Finales de carrera, microinterruptores

- Sensores, transductores

- Pirometría

- Contadores, temporizadores, medidores de panel

- Dispositivos de protección industrial

- Señalización luminosa y sonora

- Cámara termográfica

- Pantallas LED

- Botones e interruptores

- Przejdź do podkategorii

-

Cables, alambres Litz, conductos, conexiones flexibles

- alambres

- Pasamuros y acopladores de cables

- cables Litz

-

Cables para aplicaciones especiales

- Los cables de extensión y compensación

- Cables para termopares

- Los cables de conexión a PT czyjnków

- Multicore cables temp. -60 ° C a + 1400 ° C

- cables de media tensión SILICOUL

- ignición alambres

- Los cables calefactores

- temp núcleo único. -60 ° C a + 450 ° C

- conductores de trenes

- El calentamiento de los cables en el Ex

- Przejdź do podkategorii

- camisas

-

trenzas

- trenzas planas

- trenzas ronda

- trenza muy flexible - plana

- trenza muy flexible - Ronda

- Copper cilíndrico trenzado

- Copper protector de la trenza y cilíndrica

- cintas de conexión flexibles

- Trenzas cilíndrico galvanizado y acero inoxidable

- Aislamiento de PVC trenzas de cobre - Temperatura 85 ° C

- aluminio trenzado plano

- Kit de conexión - trenzas y tubos

- Przejdź do podkategorii

- Accesorios para la tracción

- Terminales de cable

- barras flexibles aisladas

- carril flexible multicapa

- sistemas de gestión de cables

- Przejdź do podkategorii

- Zobacz wszystkie kategorie

-

Semiconductores

-

-

- Suppliers

-

Applications

- Accionamientos de CA y CC (inversores)

- Automatización HVAC

- Automatización industrial

- Automatización industrial

- Calentamiento por inducción

- Componentes para atmósferas potencialmente explosivas (EX)

- Dispositivos de protección industrial

- Energy bank

- Equipos para Armarios de Distribución, Control y Telecomunicaciones

- Fuentes de alimentación (UPS) y sistemas rectificadores

- Impresión

- Máquinas de soldar y máquinas de soldar

- Máquinas herramientas CNC

- Máquinas para secar y procesar madera

- Máquinas para termoformado de plásticos

- Medición y regulación de temperatura

- Medición y regulación de temperatura

- Minería, metalurgia y fundación

- Motores y transformadores

- Tracción de tranvía y ferrocarril

-

Instalación

-

-

Inductores

-

-

Dispositivos de inducción

-

-

Servicio

-

- Contact

- Zobacz wszystkie kategorie

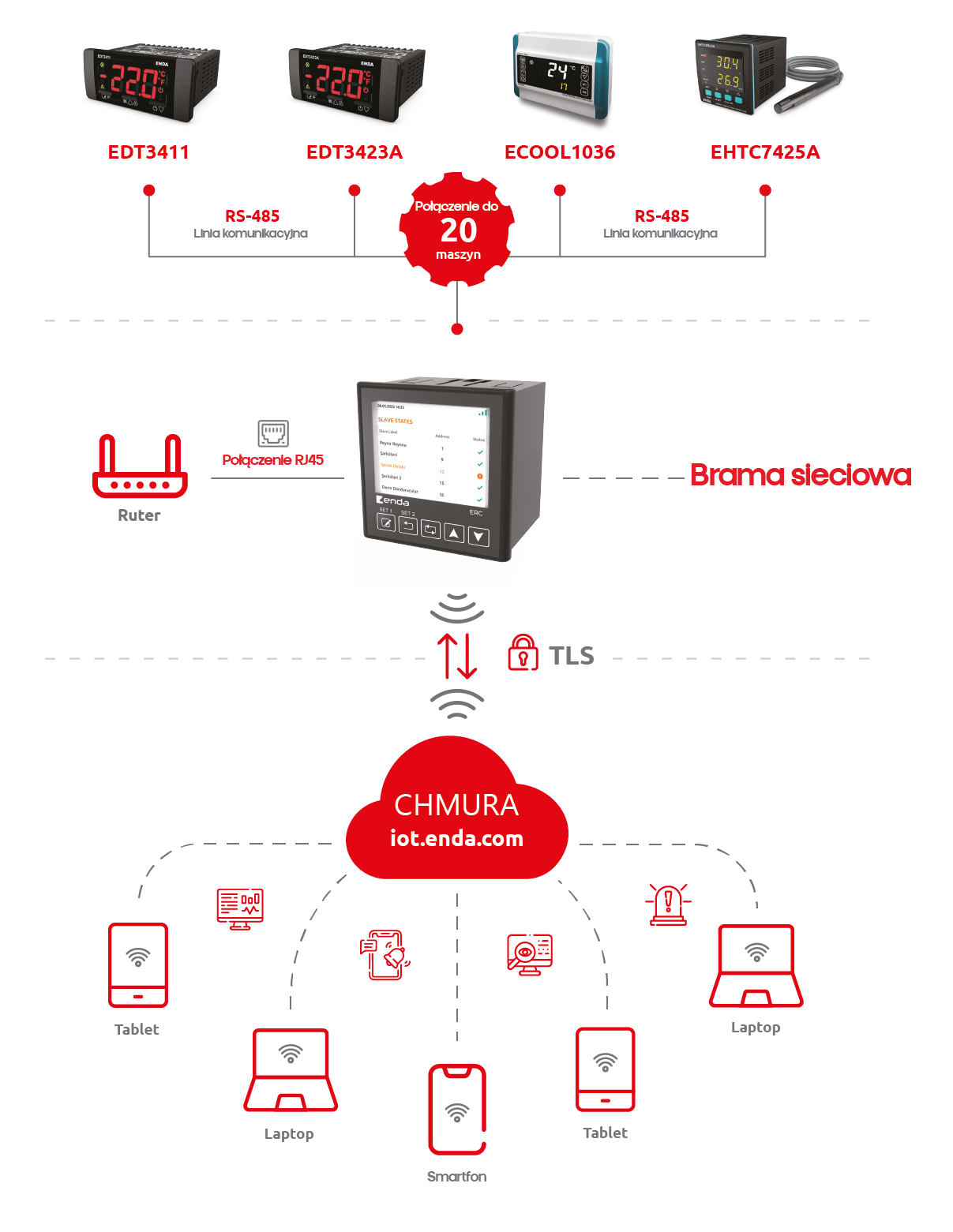

Increase Efficiency and Security: How the ERC Industrial IoT Gateway Modernizes Production Management

Integration of Industrial Devices with the Internet

Elevate your business by integrating industrial devices with the Internet. Real-time data collection and analysis enable quick, optimal decision-making and increased efficiency. All of this is within reach thanks to the ERC IoT Gateway.

Industrial Monitoring and Remote Management

Monitor production chains and equipment status, accurately identify equipment that requires maintenance, and streamline business operations with remote control systems embedded in machines.

Enable users to leverage valuable data and information through an IoT interface. A cloud-based portal provides remote management and oversight of industrial controllers, offering numerous benefits for users.

With remote access to industrial control devices, it’s possible to quickly and easily modify settings, monitor performance, and manage operations, allowing problems to be solved without the need for on-site visits.

Reliable IoT Technology in the Food Industry

IoT technology, widely used in various sectors of the food industry, significantly increases business efficiency. The use of smart devices and sensors in production, storage, transportation, and sales allows for process optimization and improved operational quality.

Food Safety

Monitoring production, storage, and transportation conditions of food products using IoT devices.

Efficiency

Efficient time utilization in production, storage, and sales processes.

Consumer Trust

Ensuring accurate and reliable information transfer through tracking.

Automation

Minimization of error margins through process automation.

Industrial IoT Gateways ERC: Key Features and Functions

Industrial IoT gateways are advanced technological devices, with their effectiveness determined by their technical parameters. Among them, the ERC IoT gateway stands out. It possesses all the features one might expect from such a device. Below are some of its selected features.

Technical Features

Easy and Quick Installation Using Mobile Verification

The installation process is seamless, thanks to a one-time code sent to the designated user’s phone number. The process is quick and straightforward.

Real-time Monitoring

You can easily track real-time readings and perform extensive database queries covering longer periods, all according to the selected time frame.

Alarm Management

Manage all parameters requiring monitoring. Control is easier and faster with features such as assigning specific parameters to key units and categorizing monitoring parameters into different contact groups.

Push Notifications via SMS and Email

The push notification system via SMS and email ensures quick and reliable control of industrial devices during alarm events.

Reliability and Security

Data is secured using encryption algorithms at the banking industry standard. The fault-tolerant infrastructure prevents data loss and blocks third-party access to data and devices.

User Management

Create and approve subordinate users directly from the super-administrator interface. Assign custom read-only or read-and-write permissions for these users in the selected gateway.

Periodic Reporting

Automatically send selected parameters to specified email addresses at chosen time intervals.

Monitor All Paired Gateways from a Single Interface

Easy navigation through all gateways thanks to an intuitive IoT interface. With cloud architecture, it’s convenient to assign multiple gateways to a specific email address.

Simple Update Process

The latest software version can be found and installed from the device, ensuring that the gateway always operates in the most optimal way.

Display

As one of the few gateways on the market, ERC features a display, making it easy to read measurements and configure RS-485 settings.

Communication

Communication is carried out using the standard Modbus protocol, allowing connection with the vast majority of controllers available on the market.

The use of cloud technology significantly facilitates data access and parameter control. Additionally, it greatly reduces the number of cables needed to connect the system. This is a very convenient solution that any entrepreneur looking to modernize their operations should consider. This is exactly the solution provided by the ERC IoT gateway. Let's look at the key differences by comparing the ERC gateway to a system without cloud access.

Key Differences Compared to Non-Cloud Solutions

- A cloud-based system allows for monitoring of maintenance, safety, and system performance

- No issues with cable routing, just connect the controller to the ERC and access it from anywhere

- Encryption meets industry standards on every communication channel

- Monitor and control all locations from a single integrated user interface without needing to manually log in to each gateway, maintain IP addresses, and troubleshoot connectivity issues

Conclusion

Integrating industrial devices with the Internet through the ERC industrial IoT gateway significantly increases operational efficiency and safety. This technology enables remote monitoring and management of devices in real-time, allowing for quick response to issues and process optimization. By using the cloud, businesses can reduce cable infrastructure and gain easy access to data and settings from anywhere, fostering business modernization and improving operational quality. These features make the ERC gateway a must-have for any modern industrial sector.

Producto relacionado

Publicaciones relacionadas

Nanuk protection cases - perfect solution for work in difficult conditions

Nanuk protection cases - perfect solution for work in difficult conditions

Tecnologías de iluminación industrial

Tecnologías de iluminación industrial

Power supply management

Power supply management

Deja un comentario