Debes estar logueado

Category

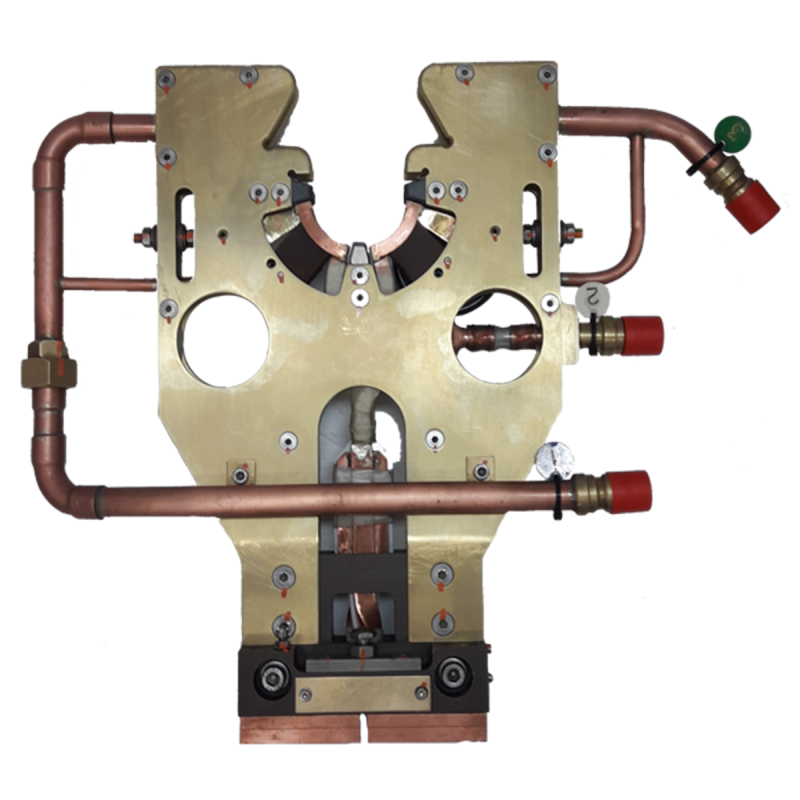

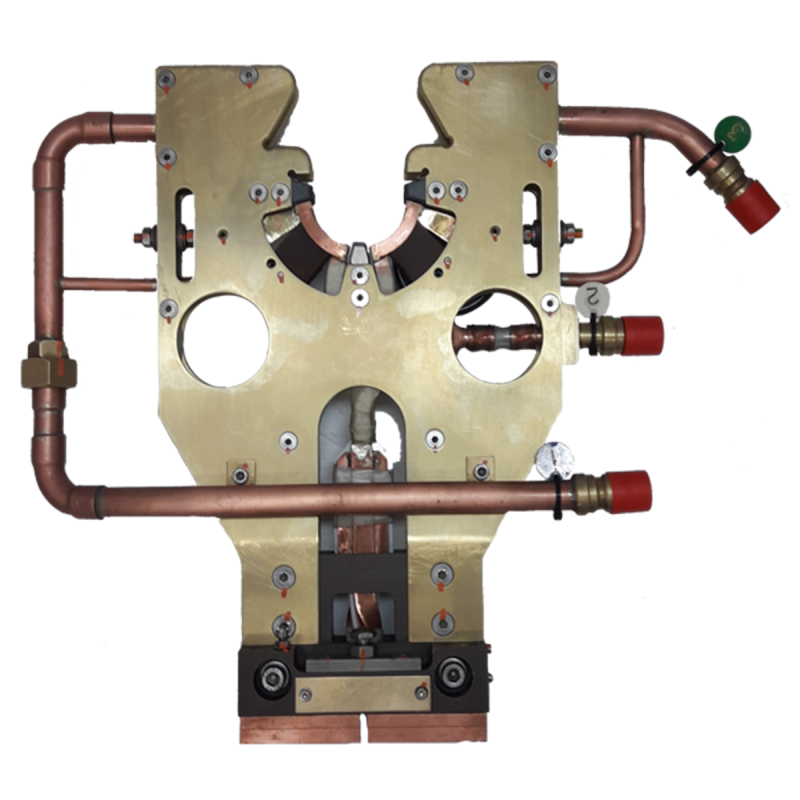

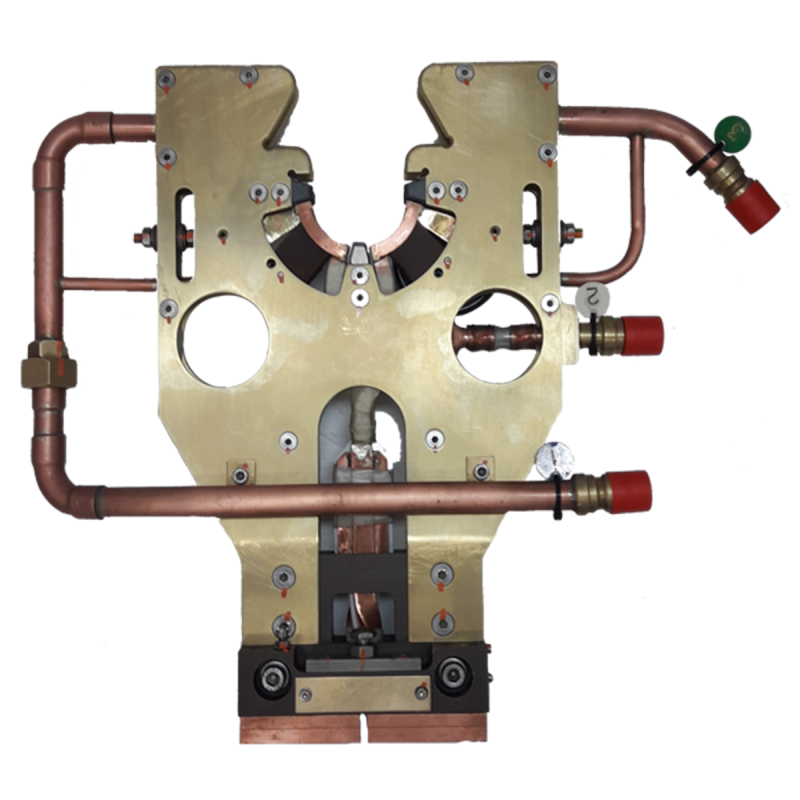

Las fotos son solo para fines informativos. Ver especificaciones de producto

please use latin characters

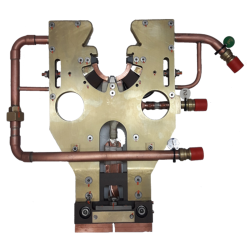

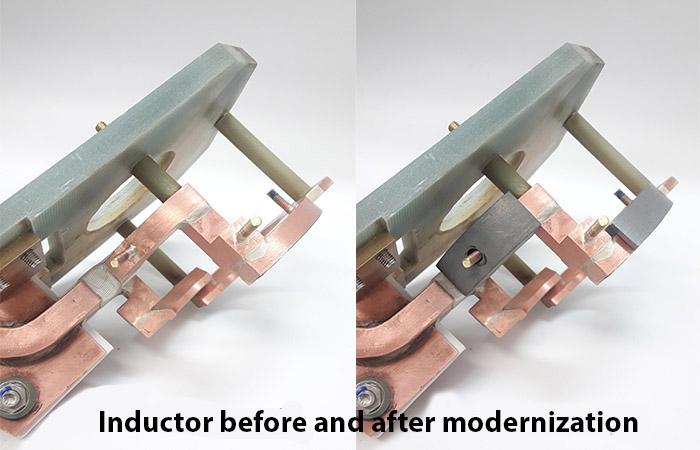

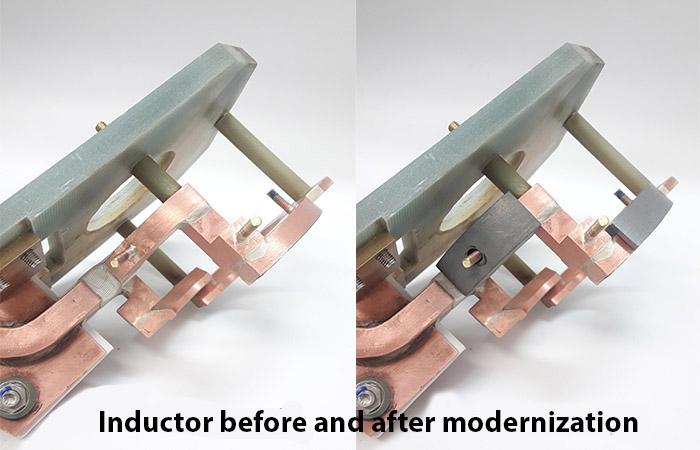

The modernization of the inductor is the introduction of changes in its design aimed at:

Example:

The change in the shape of the inductor head and the use of magnetic field concentrators allowed to increase the precision and reduce heating in non-hardened zones, increase the efficiency of the process by more precisely focusing energy to the hardened area, reducing the heating time while maintaining the same value of power absorbed.

¿Estás interesado en este producto? ¿Necesita información adicional o precios individuales?

Usted debe estar conectado

The modernization of the inductor is the introduction of changes in its design aimed at:

Example:

The change in the shape of the inductor head and the use of magnetic field concentrators allowed to increase the precision and reduce heating in non-hardened zones, increase the efficiency of the process by more precisely focusing energy to the hardened area, reducing the heating time while maintaining the same value of power absorbed.

The use of induction heating in the manufacture of industrial equipment

The use of induction heating in the manufacture of industrial equipment

Su agradecimiento a la reseña no pudo ser enviado

Reportar comentario

Reporte enviado

Su reporte no pudo ser enviado

Escriba su propia reseña

Reseña enviada

Su reseña no pudo ser enviada