Debes estar logueado

Category

Las fotos son solo para fines informativos. Ver especificaciones de producto

please use latin characters

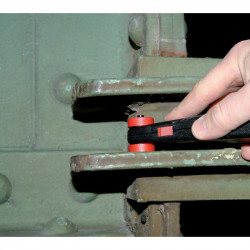

Do you produce damage reports and value appraisals and require a coating thickness gauge for the vehicle assessment? Do you value easy operation and reliable results? If so, the QNix® 1500 is the right gauge for you.

Due to the 3-point contact, you can position the QNix® 1500 easily and safely and always receive reliable measurement results. By means of two independent measurement probes, you instantly recognise on which basic substrate you are taking a measure. You can take coating thickness measurements on steel, iron (Fe) and non-ferrous metals (NFe) like aluminium, zinc, copper and brass. All QNix® coating thickness gauges function according to our easy-to-use principle: position, measure and read.

QNix® 1200 – Gauge with 3-point contact for ferrous substrates is ergonomic, quick and durable.

QNix® 1500 – Gauge with 3-point contact and 2 independent measurement probes for Fe and NFe substrates. The device can be turned and thereby the measurement method can be easily changed.

| Functions | QNix® 1200 | QNix® 1500 |

|---|---|---|

| 3-point contact | ✔ | ✔ |

| Acoustic measurement confirmation | ✔ | ✔ |

| Unit switch µm/mil | ✔ | ✔ |

| Zero-point calibration on reference plate | ✔ | ✔ |

| Measurements on FE | ✔ | ✔ |

| Measurements on NFe | ✔ | |

| 2 independent measurement probes | ✔ |

| Measuring principle | two magnetic measuring principles: Fe: magnetic induction - see Fe* (ISO 278); NFe: eddy current - see NFe* (ISO 2360) |

|---|---|

| Probe type | integrated |

| According to the standard | see: our range of probes for the QNix® 1500/1200 |

| Switching units | µm/mil |

| Period between measurements | 1250 ms |

| Measurement value display | from 0 – 999 in µm, in mm as of 1000 µm |

| Display resolution | 0.1 µm in the range 0 – 99.9 µm 1 µm in the range 100 – 999 µm 0.01 mm starting at 1000 µm |

| Display | LCD |

| Operating temperature range | 0 - 50°C |

| Permissible storage temperature | -10°C - 60°C |

| Power supply | 1 x battery: 9V (type 9V) |

| Dimensions (L x W x H in mm) | 166 x 64 x 34 |

| Weight incl. batteries | 150 g |

Fe* – Measurement of non-ferrous or non-ferromagnetic coatings on ferromagnetic substrate, such as measurements on iron or steel substrate.

NFe* – Measurement of non-ferrous or non-ferromagnetic and non-electrically conductive coatings on non-ferrous or non-ferromagnetic and electrically conductive substrate, such as measurements on aluminium, zinc, copper, brass and certain stainless steel substrates.

¿Estás interesado en este producto? ¿Necesita información adicional o precios individuales?

Usted debe estar conectado

Do you produce damage reports and value appraisals and require a coating thickness gauge for the vehicle assessment? Do you value easy operation and reliable results? If so, the QNix® 1500 is the right gauge for you.

Due to the 3-point contact, you can position the QNix® 1500 easily and safely and always receive reliable measurement results. By means of two independent measurement probes, you instantly recognise on which basic substrate you are taking a measure. You can take coating thickness measurements on steel, iron (Fe) and non-ferrous metals (NFe) like aluminium, zinc, copper and brass. All QNix® coating thickness gauges function according to our easy-to-use principle: position, measure and read.

QNix® 1200 – Gauge with 3-point contact for ferrous substrates is ergonomic, quick and durable.

QNix® 1500 – Gauge with 3-point contact and 2 independent measurement probes for Fe and NFe substrates. The device can be turned and thereby the measurement method can be easily changed.

| Functions | QNix® 1200 | QNix® 1500 |

|---|---|---|

| 3-point contact | ✔ | ✔ |

| Acoustic measurement confirmation | ✔ | ✔ |

| Unit switch µm/mil | ✔ | ✔ |

| Zero-point calibration on reference plate | ✔ | ✔ |

| Measurements on FE | ✔ | ✔ |

| Measurements on NFe | ✔ | |

| 2 independent measurement probes | ✔ |

| Measuring principle | two magnetic measuring principles: Fe: magnetic induction - see Fe* (ISO 278); NFe: eddy current - see NFe* (ISO 2360) |

|---|---|

| Probe type | integrated |

| According to the standard | see: our range of probes for the QNix® 1500/1200 |

| Switching units | µm/mil |

| Period between measurements | 1250 ms |

| Measurement value display | from 0 – 999 in µm, in mm as of 1000 µm |

| Display resolution | 0.1 µm in the range 0 – 99.9 µm 1 µm in the range 100 – 999 µm 0.01 mm starting at 1000 µm |

| Display | LCD |

| Operating temperature range | 0 - 50°C |

| Permissible storage temperature | -10°C - 60°C |

| Power supply | 1 x battery: 9V (type 9V) |

| Dimensions (L x W x H in mm) | 166 x 64 x 34 |

| Weight incl. batteries | 150 g |

Fe* – Measurement of non-ferrous or non-ferromagnetic coatings on ferromagnetic substrate, such as measurements on iron or steel substrate.

NFe* – Measurement of non-ferrous or non-ferromagnetic and non-electrically conductive coatings on non-ferrous or non-ferromagnetic and electrically conductive substrate, such as measurements on aluminium, zinc, copper, brass and certain stainless steel substrates.

Su agradecimiento a la reseña no pudo ser enviado

Reportar comentario

Reporte enviado

Su reporte no pudo ser enviado

Escriba su propia reseña

Reseña enviada

Su reseña no pudo ser enviada