Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

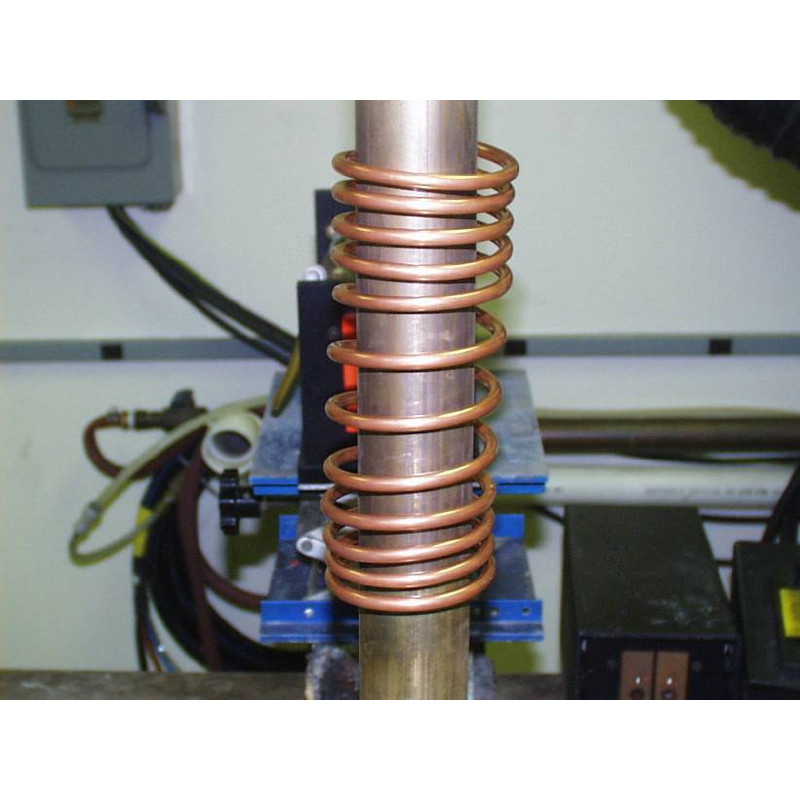

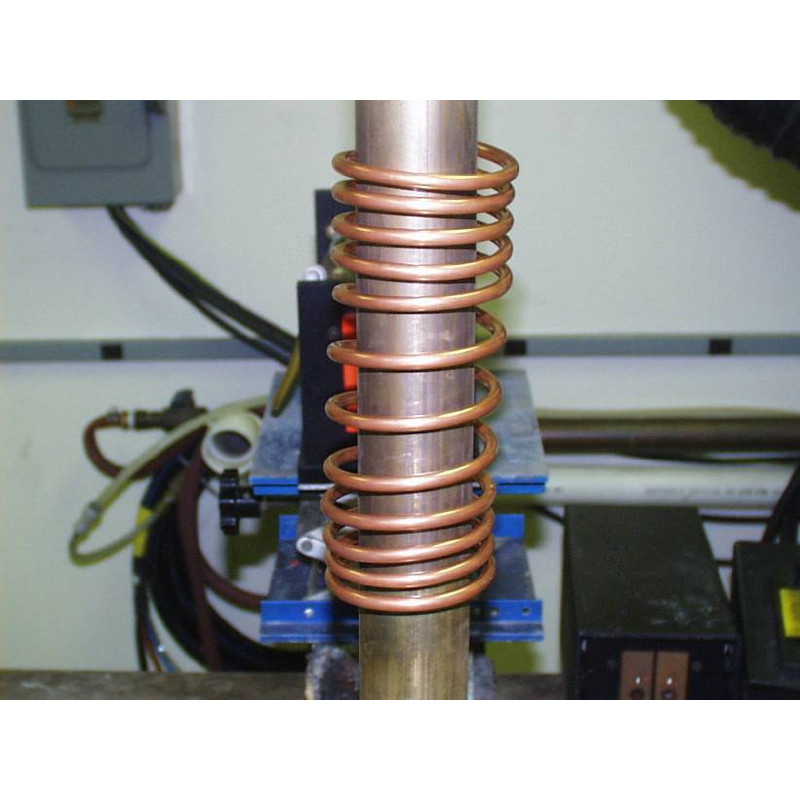

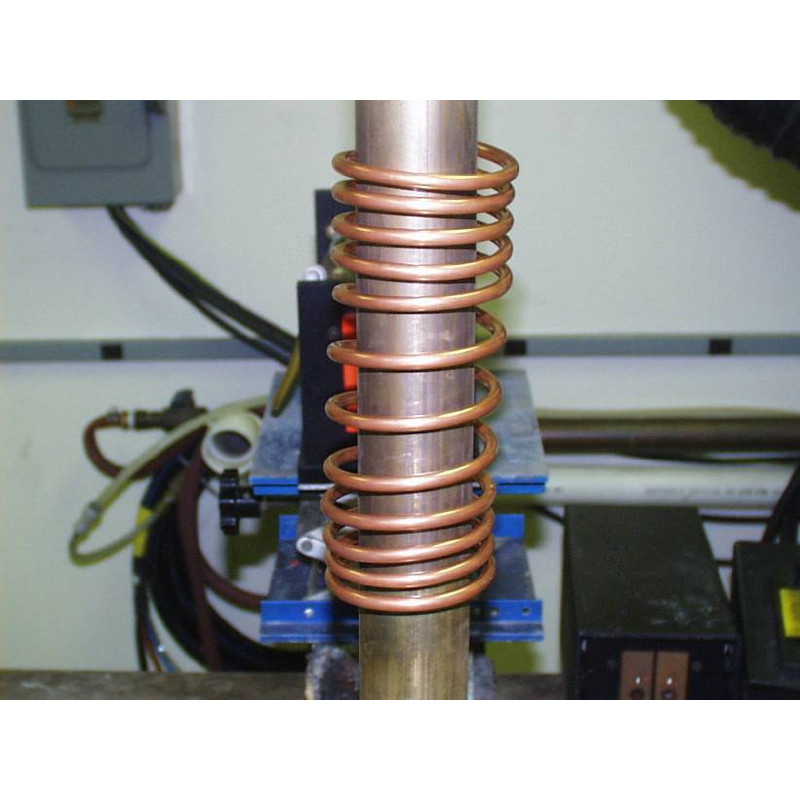

Objective: Annealing brass and bronze tubing for bending in a mandrel bender to form handrails.

Frequency: 228 kHz

Temperature: 1000 °F (538 °C)

A twelve turn helical coil is used to heat an 8” (20.3cm) area 3” (7.6cm) above the end of the tube. Each of the four tubes require a different heat cycle and time to reach the required temperature. Please see the chart below for each tube.

| 1.5" | 1.5" | 2" | 2" | |

| Brass | Bronze | Brass | Bronze | |

| Heat Cycle Time [s] | 80 | 100 | 100 | 120 |

| Power [kW] | 4 | 4.15 | 3.1 | 3.4 |

| Current [A] | 248 | 255 | 200 | 212 |

| Frequency [kHz] | 197 | 197 | 228 | 228 |

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Objective: Annealing brass and bronze tubing for bending in a mandrel bender to form handrails.

Frequency: 228 kHz

Temperature: 1000 °F (538 °C)

A twelve turn helical coil is used to heat an 8” (20.3cm) area 3” (7.6cm) above the end of the tube. Each of the four tubes require a different heat cycle and time to reach the required temperature. Please see the chart below for each tube.

| 1.5" | 1.5" | 2" | 2" | |

| Brass | Bronze | Brass | Bronze | |

| Heat Cycle Time [s] | 80 | 100 | 100 | 120 |

| Power [kW] | 4 | 4.15 | 3.1 | 3.4 |

| Current [A] | 248 | 255 | 200 | 212 |

| Frequency [kHz] | 197 | 197 | 228 | 228 |

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé.

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé