Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

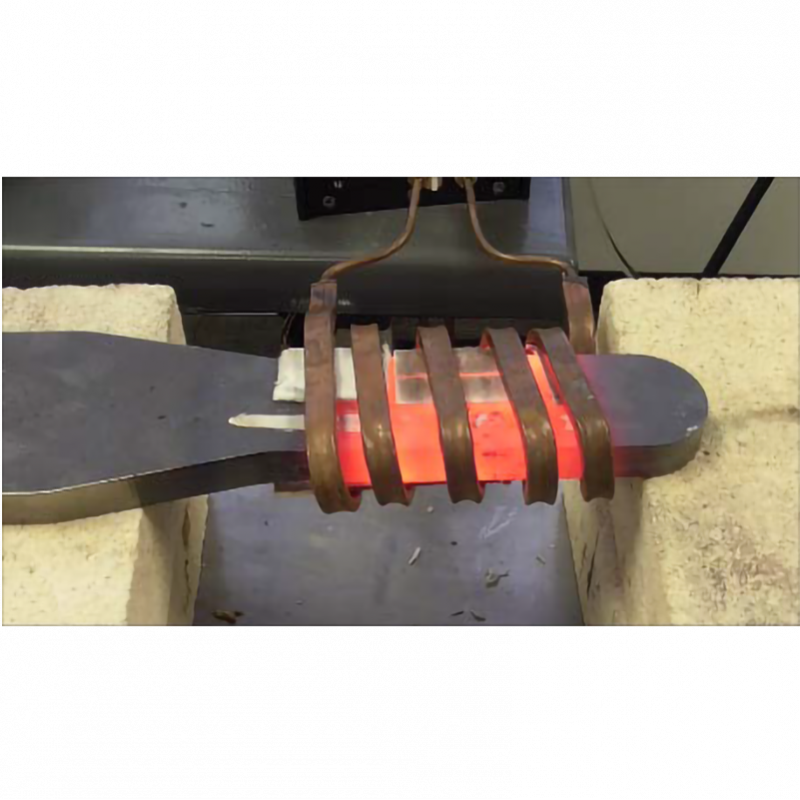

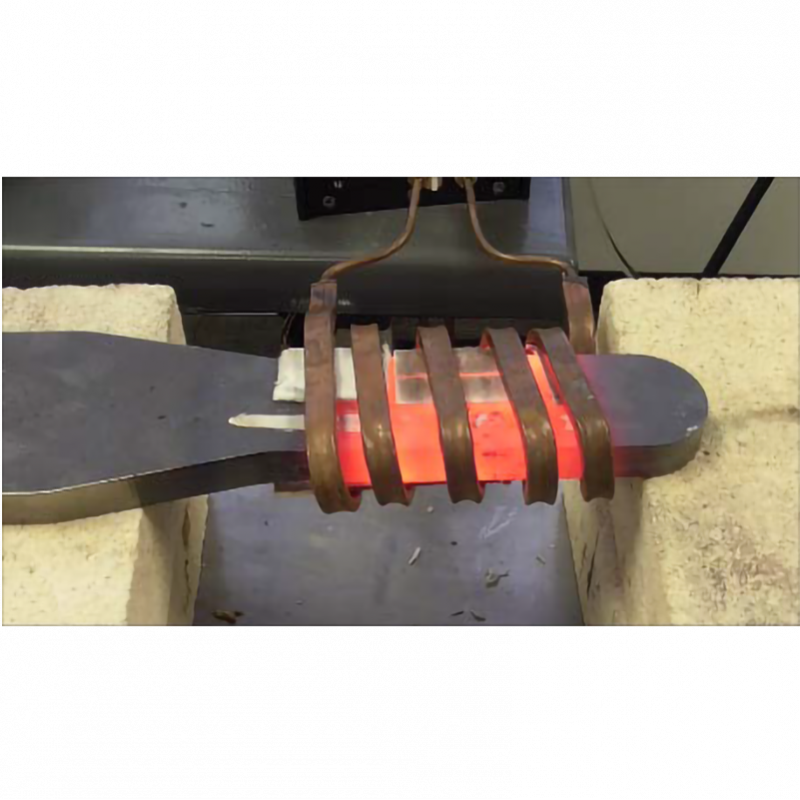

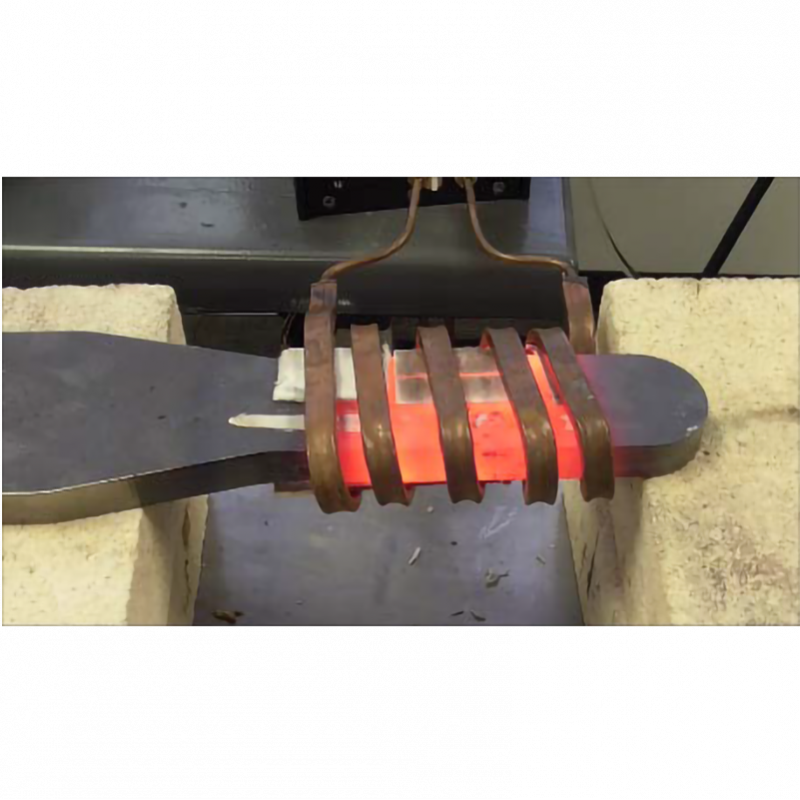

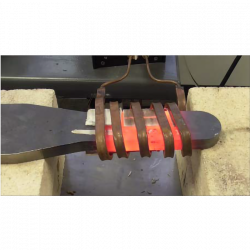

Objective: To heat a magnetic steel part for a forming application; the client had been using a torch for the application.

Frequency: 125 kHz

Material: Magnetic steel part

Temperature: 1700 °F (927 °C)

Temperature indicating paint was applied to the part to easily identify when it achieved temperature, and then the induction power was turned on. It took about three minutes for the part to reach 1700 °F (927 °C) at 10 kW and two minutes and twenty seconds with 15 kW for this through-Curie heating application.

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Objective: To heat a magnetic steel part for a forming application; the client had been using a torch for the application.

Frequency: 125 kHz

Material: Magnetic steel part

Temperature: 1700 °F (927 °C)

Temperature indicating paint was applied to the part to easily identify when it achieved temperature, and then the induction power was turned on. It took about three minutes for the part to reach 1700 °F (927 °C) at 10 kW and two minutes and twenty seconds with 15 kW for this through-Curie heating application.

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé