Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

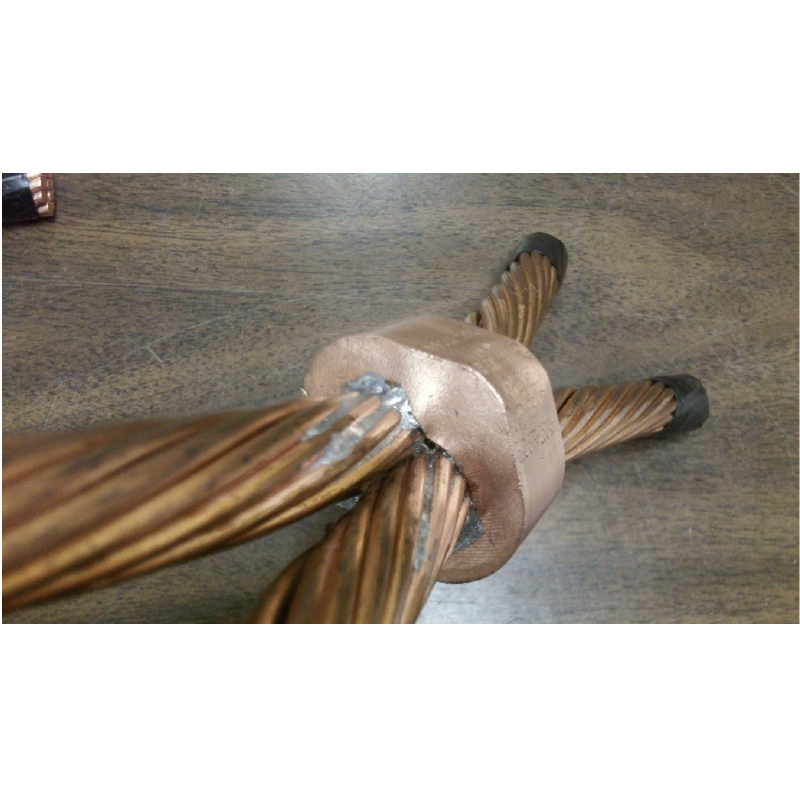

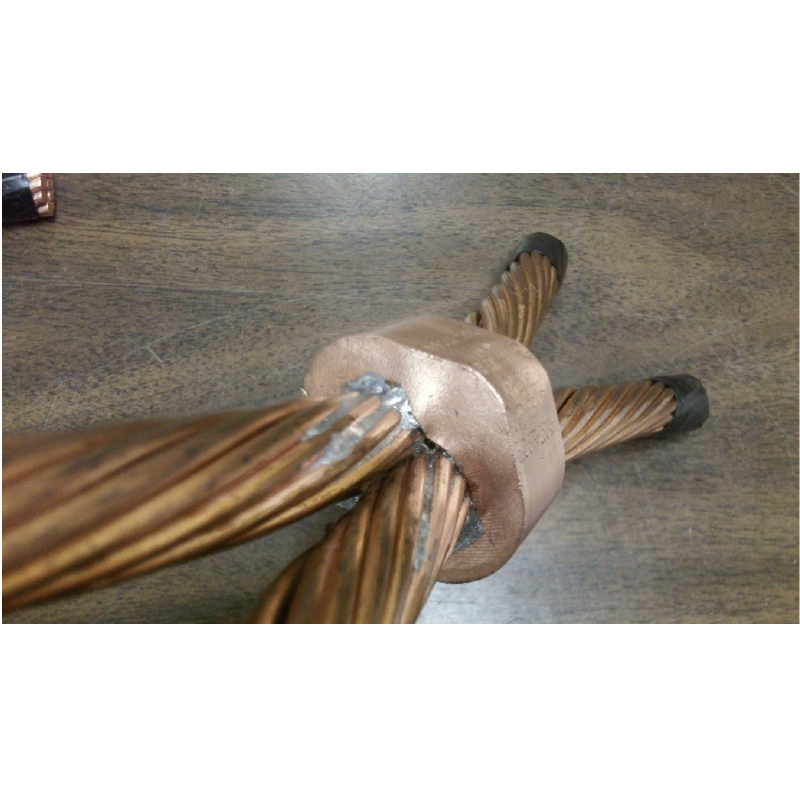

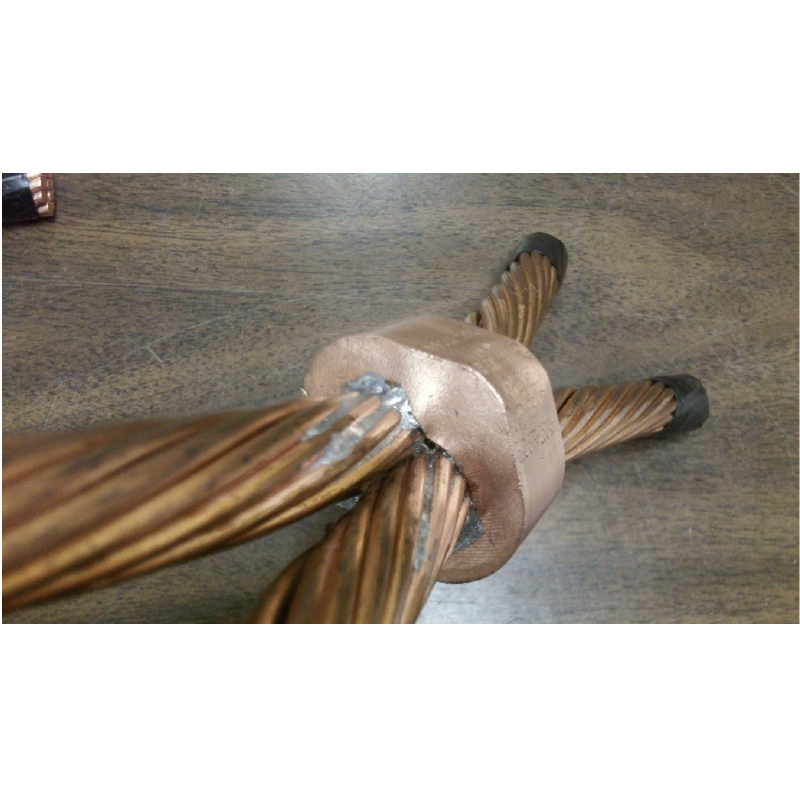

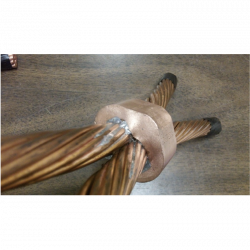

Objective: To heat a copper lug and a wire to temperature for a soldering application to create grounding connections.

Frequency: 109 kHz

Material: Wire and lug

Temperature: 370 °F (188 °C)

The parts were fluxed and the solder wire was folded two times and twisted to enable a greater feed rate. The assembly was then placed in the coil and the power was turned on. The coil was designed to focus heat on the large lug and to keep solder from running over the wires. After 40 seconds, the assembly reached soldering temperature.

It was observed that the lug could easily be filled with solder when it’s placed in a vertical direction and the solder will run out of the bottom when full. If the lug was oriented in a horizontal position the solder could be more readily kept in and around the lug.

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Objective: To heat a copper lug and a wire to temperature for a soldering application to create grounding connections.

Frequency: 109 kHz

Material: Wire and lug

Temperature: 370 °F (188 °C)

The parts were fluxed and the solder wire was folded two times and twisted to enable a greater feed rate. The assembly was then placed in the coil and the power was turned on. The coil was designed to focus heat on the large lug and to keep solder from running over the wires. After 40 seconds, the assembly reached soldering temperature.

It was observed that the lug could easily be filled with solder when it’s placed in a vertical direction and the solder will run out of the bottom when full. If the lug was oriented in a horizontal position the solder could be more readily kept in and around the lug.

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé