Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

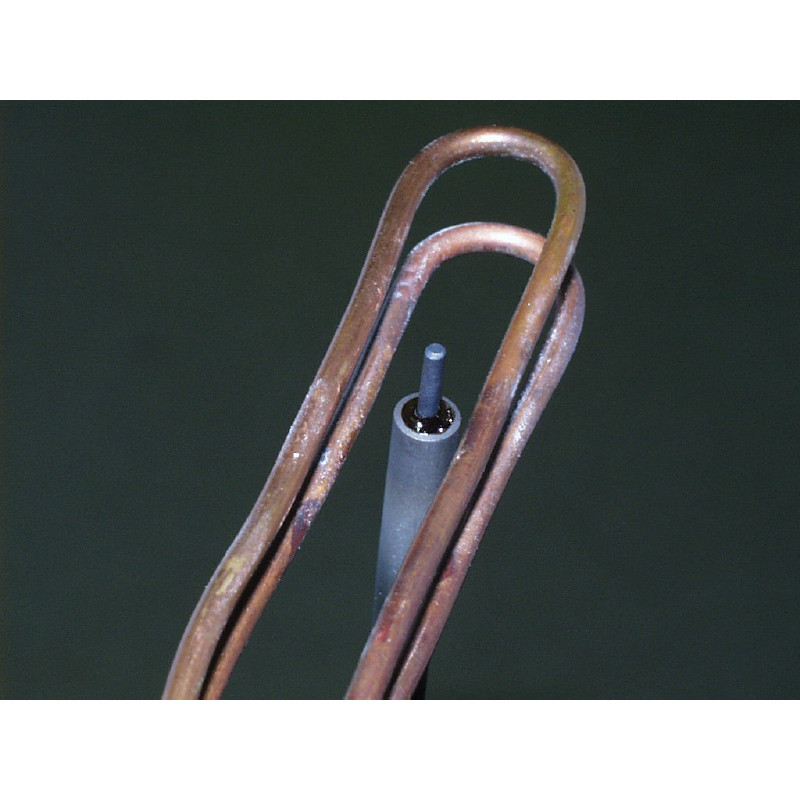

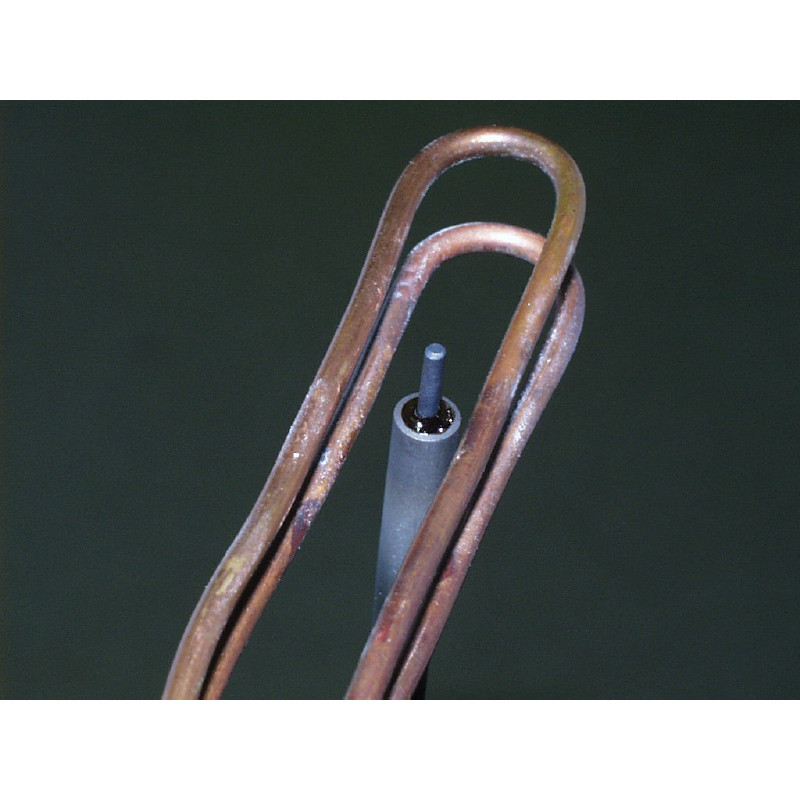

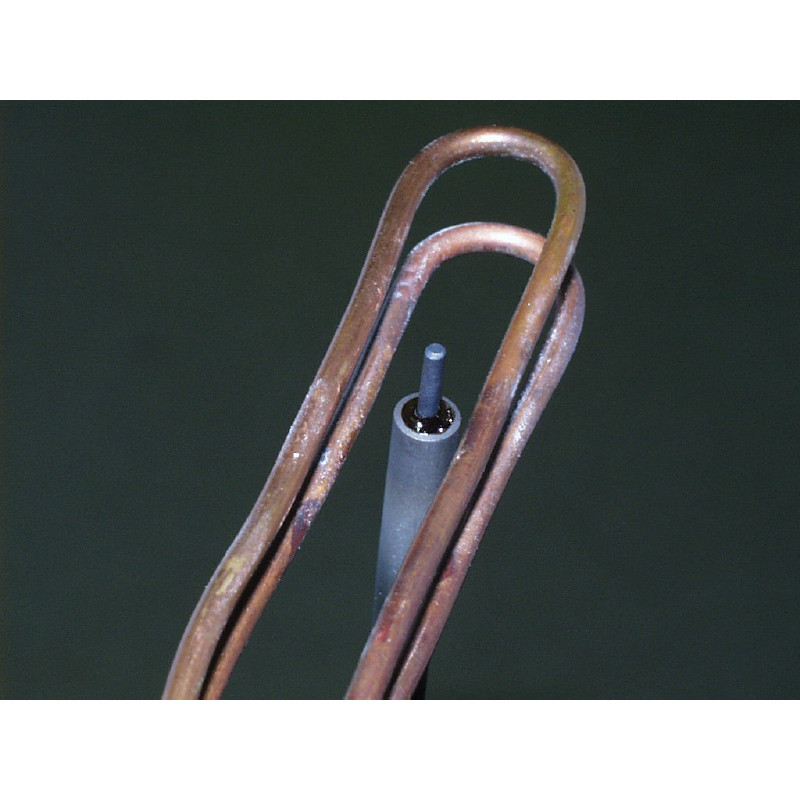

Objective: To heat seal both ends of a stainless steel heater assembly to 300-500 ºF (149-260 ºC) and melt glass preforms.

Frequency: 212 kHz

Material: Stainless steel rods 1/2” to 3” (12.7mm to 76.2mm) diameters, glass preforms.

Temperature: 300-500 °F (149-260 °C)

A two-turn elongated helical coil is used to heat 5 to 7 stainless steel rods simultaneously for 60 seconds. The glass preforms melt and create a hermetic seal. After the first end is heated the parts are repositioned to heat the opposite end.

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Objective: To heat seal both ends of a stainless steel heater assembly to 300-500 ºF (149-260 ºC) and melt glass preforms.

Frequency: 212 kHz

Material: Stainless steel rods 1/2” to 3” (12.7mm to 76.2mm) diameters, glass preforms.

Temperature: 300-500 °F (149-260 °C)

A two-turn elongated helical coil is used to heat 5 to 7 stainless steel rods simultaneously for 60 seconds. The glass preforms melt and create a hermetic seal. After the first end is heated the parts are repositioned to heat the opposite end.

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé