Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

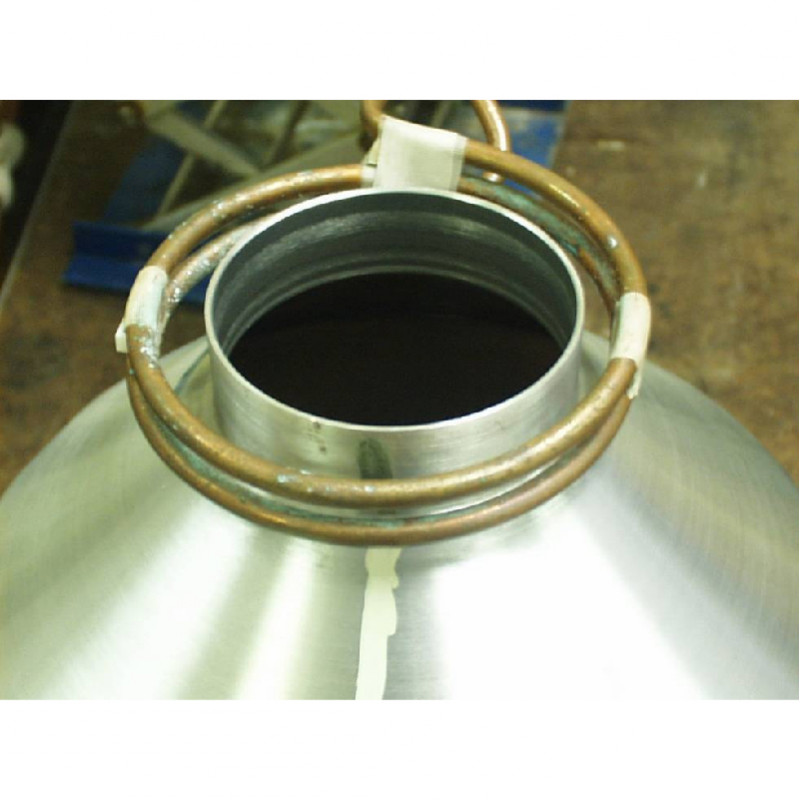

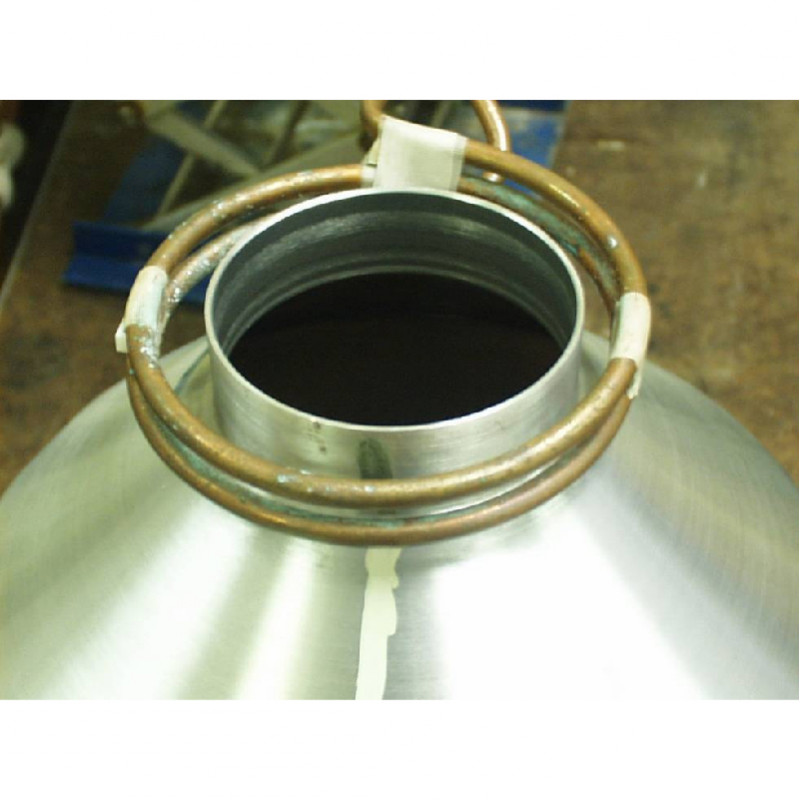

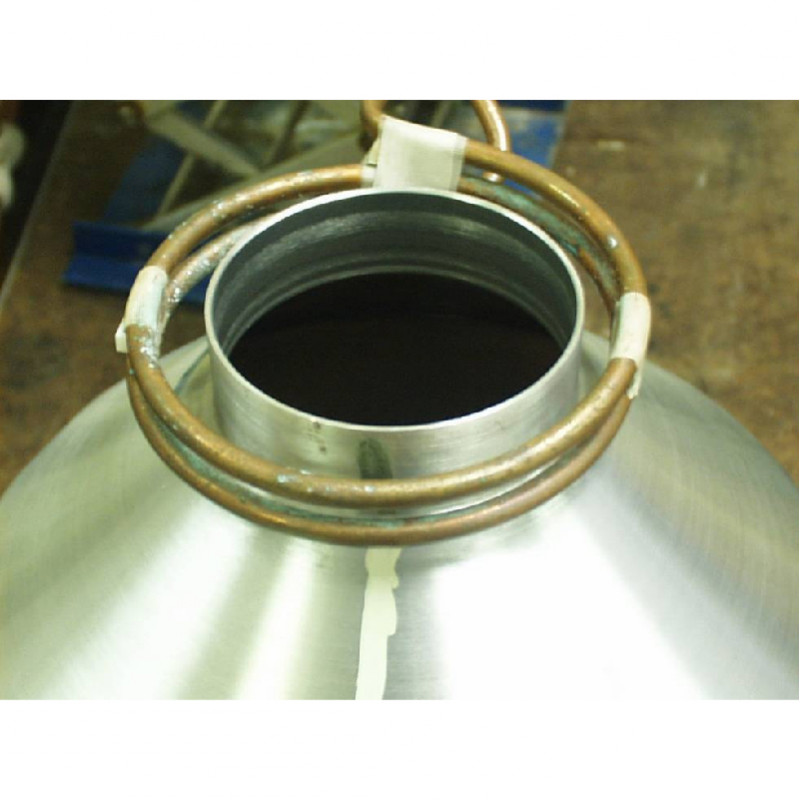

Objective: Annealing a 1” lip on aluminum cryogenic dewar* that has been work hardened during the process of spin forming.

Frequency: 303 kHz

Material: Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick.

Temperature: 800 °F (427 °C)

A two turn helical coil is used to heat the lip on the cryogenic dewar. The dewar is placed in the coil and power is applied for 2 minutes to anneal the required 1” heat zone.

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Objective: Annealing a 1” lip on aluminum cryogenic dewar* that has been work hardened during the process of spin forming.

Frequency: 303 kHz

Material: Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick.

Temperature: 800 °F (427 °C)

A two turn helical coil is used to heat the lip on the cryogenic dewar. The dewar is placed in the coil and power is applied for 2 minutes to anneal the required 1” heat zone.

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé