Vous devez être connecté

-

revenirX

-

Composants

-

-

Category

-

Semi-conducteurs

- La diode

- Les thyristors

- Modules de puissance isolés

- Ponts redresseurs

-

Transistors

- Transistors | GeneSiC

- Modules MOSFET SiC | Mitsubishi

- Modules MOSFET SiC | STARPOWER

- Modules MOSFET SiC ABB

- Modules IGBT | MITSUBISHI

- Modules de transistors | MITSUBISHI

- Modules MOSFET | MITSUBISHI

- Modules de transistors | ABB

- Modules IGBT | POWEREX

- Modules IGBT | INFINEON (EUPEC)

- Composants semiconducteurs en carbure de silicium

- Aller à la sous-catégorie

- Circuits de commande

- Blocs de puissance

- Aller à la sous-catégorie

- Transducteurs électriques

-

Composants passifs (condensateurs, résistances, fusibles, filtres)

- Résistances

-

Fusibles

- Fusibles miniatures pour c.imp. série ABC et AGC

- Fusible rapides tubulaires

- Cartouches de courbe GL/GG et AM

- Cartouches ultrarapides

- Fusibles à action rapide (norme britannique et américaine)

- Fusibles à action rapide (norme européenne)

- Fusibles de traction

- Cartouche de haute tension

- Aller à la sous-catégorie

-

Condensateurs

- Condensateurs pour moteurs

- Condensateurs électrolitiques

- Condensateurs de type snubbers

- Condensateurs de puissance

- Condensateurs pour circuits continus

- Condensateurs de compensation de puissance

- Condensateurs de haute tension

- Condensateurs pour chauffage par induction

- Condensateurs pour impulsions

- Condensateurs DC LINK

- Condensateurs pour circuits AC/DC

- Aller à la sous-catégorie

- Filtres anti-interférences

- Supercondensateurs

-

Protection contre les surtensions

- Protection contre les surtensions pour les applications coaxiales

- Protection contre les surtensions pour les systèmes de vidéosurveillance

- Parafoudres de ligne électrique

- Protection contre surtensions pour LED

- Parafoudres pour le photovoltaïque

- Protection du système de pesage

- Protection contre les surtensions pour bus de terrain

- Aller à la sous-catégorie

- Aller à la sous-catégorie

-

Relais et contacteurs

- Théorie relais et contacteurs

- Relais statiques triphasés

- Relais statiques CC

- Régulateurs, circuits de commande et accessoires

- Démarrages progressifs et contacteurs inverseurs

- Relais electromécaniques

- Contacteurs

- Commutateurs rotatifs

-

Relais statiques monophasés

- Relais semi-conducteurs AC monophasés, série 1 | D2425 | D2450

- Relais à semi-conducteurs CA monophasés, séries CWA et CWD

- Relais à semi-conducteurs CA monophasés des séries CMRA et CMRD

- Relais à semi-conducteurs CA monophasés, série PS

- Relais semi-conducteurs AC double et quadruple, série D24 D, TD24 Q, H12D48 D

- Relais statiques monophasés, série GN

- Relais à semi-conducteurs CA monophasés, série CKR

- Relais AC monophasés SÉRIES ERDA ET ERAA pour rail DIN

- Relais CA monophasés pour courant 150A

- Relais à semi-conducteurs doubles intégrés à un dissipateur thermique pour un rail DIN

- Aller à la sous-catégorie

- Relais statiques monophasé pour c.imp.

- Relais d'interface

- Aller à la sous-catégorie

- Composants inductifs

- Radiateurs, varistances, protections thermiques

- Ventilateurs

- Climatiseurs et accessoires d'armoires électriques

-

Batteries, chargeurs, blocs d'alimentation tampon et onduleurs

- Batteries et Chargeurs - théorie

- Batteries Li-ion et non-standards. Systèmes de gestion des batteries (BMS)

- Batteries

- Chargeurs de batteries et accessoires

- Alimentation de secours UPS et alimentation tampon

- Convertisseurs de tension et accessoires pour photovoltaïque

- Stockage d'Energie

- Réservoirs de carburant

- Batteries lithium-ion

- Aller à la sous-catégorie

-

Automatique industrielle

- Futaba Drone Parts

- Interrupteurs de fin de course, micro-rupteurs

- Capteurs et convertisseurs

- Pyromètres

- Compteurs, Relais temporisés, Indicateurs de tableau

- Appareils industriels de protection

- Signalisation lumineuse et sonore

- Caméra thermique

- Afficheurs à LED

- Boutons et commutateurs

-

Enregistreurs

- Enregistreur de température à bande et afficheur numérique - AL3000

- Enregistreurs à microprocesseur avec ecran LCD série KR2000

- Enregistreur KR5000

- Indicateur avec fonction enregistrement de température et humidité HN-CH

- Matériaux consommables pour enregistreurs

- Enregistreur graphique compact 71VR1

- Enregistreur KR3000

- Enregistreur PC série R1M

- Enregistreur PC série R2M

- Enregistreur PC, 12 entrés isolées – RZMS

- Enregistreur PC, USB, 12 entrées isolées – RZUS

- Aller à la sous-catégorie

- Aller à la sous-catégorie

-

Câbles et chemins de câbles

- Fils

- Fils de Litz

- Câbles pour les applications spéciales

- Gaines

-

Tresses

- Tresses plates

- Tresses rondes

- Tresses très souples - plates

- Tresses très souples - rondes

- Tresses cuivre cylindriques

- Tresses cuivre cylindriques et protection

- Bandes de mise à la terre souples

- Tresses en acier zingué et inox

- Tresses isolantes en PVC - temp. 85°C

- Tresses plates en aluminium

- Kit de liaison - tresses et gaines

- Aller à la sous-catégorie

- Equipement pour la traction

- Cosses

- Barres flexible isolées

- Barre flexibles multicouches

- Systèmes de traçage des câbles

- Gaines annelées, tuyaux

- Aller à la sous-catégorie

- Voir toutes les catégories

-

Semi-conducteurs

-

-

- Fournisseurs

-

Applications

- Alimentations (UPS) et systèmes de redressement

- Automatisation HVAC

- Chauffage par induction

- Composants pour atmosphères potentiellement explosives (EX)

- Dispositifs de protection industriels

- Energy bank

- Équipements pour armoires de distribution, de contrôle et de télécommunications

- Impression

- L'automatisation industrielle

- L'automatisation industrielle

- Machines à souder et machines à souder

- Machines de séchage et de traitement du bois

- Machines pour le thermoformage des plastiques

- Machines-outils CNC

- Mesure et régulation de la température

- Mesure et régulation de la température

- Mines, métallurgie et fondation

- Moteurs et transformateurs

- Traction de tram et de chemin de fer

- Variateurs CA et CC (onduleurs)

-

Installation

-

-

Inducteurs

-

-

Appareils à induction

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

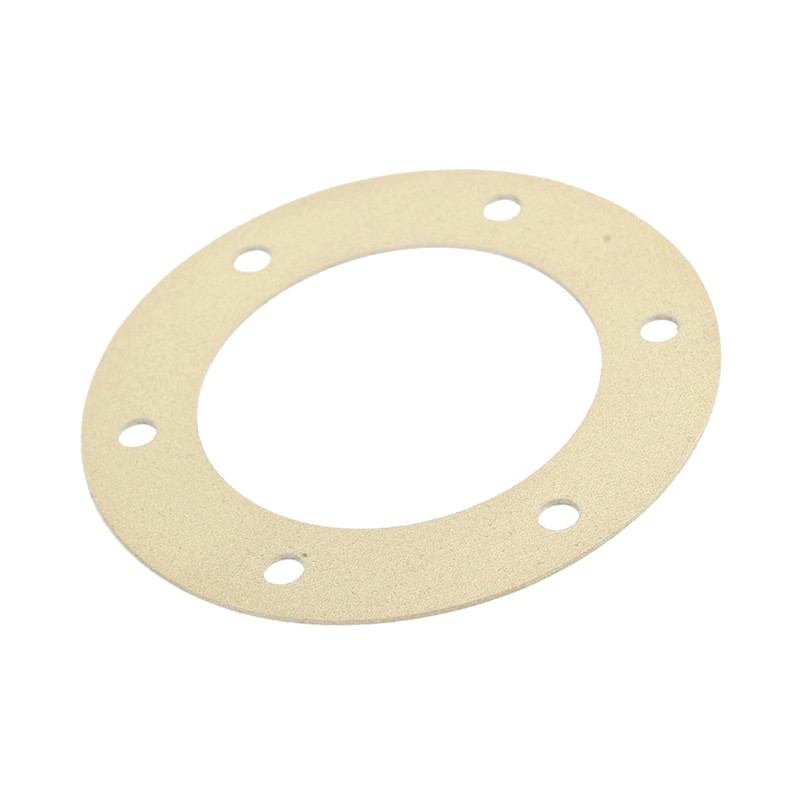

The technique of printing conductive elastomers is a novel and very cost effective method of producing gaskets when compared to conventional means. The printed process produces a highly selective deposit resulting in negligible wastage. Below are its major advantages:

- Cost effective versus conventional gaskets, e.g., die cut from moulded or calendered

sheet. - Printed raised beads improve stress contact in lightly loaded flanges on hardware.

- The gasket can be printed onto a conductive carrier (e.g., metal or plastic) to ease

assembly. - Component hardware (e.g., panels, covers, providing the surface the gasket is to be

located on is flat), can have the gasket printed direct onto the relevant surface, greatly

improving assembly. - Secondary environmental sealing can be incorporated into the gasket.

Comparative properties

| EcE Material Reference (Type) | 3A | 3B | 3D | 3G | 31 | 3J | 3A/1 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Elastomer Type (Sil - Silicone) | Sil | Sil | Sil | Sil | Sil | Sil | Sil | |||||

| Filler Material | Ag/Ni | Ag/Cu | Ag/Al | Ag | Ag/szkło | Ag/Gr | Al | |||||

| Color | Tan | Tan | Tan | Tan | Tan | Grey | Black | |||||

| Electrical Properties | ||||||||||||

| Volume Resistivity (ohm.cm) | 5 | 5 | 8 | 5 | 5 | 5 | 12 | |||||

| Shielding Effectiveness (dB) 10 KHz | 1 068 | 112 | 1 115 | 9 299 | 8 315 | 1 068 | 5 816 | |||||

| to | ||||||||||||

| 700 MHz | 121 | 1 283 | 1 226 | 1 007 | 9 148 | 1 218 | 6 531 | |||||

| (Min/Max) | ||||||||||||

| Shielding Effectiveness (dB) 200 KHz (H-Field) |

70 | 70 | 70 | 70 | 55 | 70 | 50 | |||||

| 100 MHz (E-Field) | 105 | 115 | 110 | 115 | 95 | 95 | 72 | |||||

| 500 MHz (E-Field) | 105 | 115 | 105 | 115 | 95 | 90 | 70 | |||||

| 2 GHz (Plane Wave) | 100 | 115 | 100 | 115 | 95 | 90 | 65 | |||||

| 10 GHz (fala płaska) | 100 | 115 | 100 | 115 | 95 | 90 | 65 | |||||

| EcE Material Reference (Type) | 3A/1 | 3B/1 | 3D/1 | 31/1 | 3J/2 | 3K/1 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Elastomer Type (Sil - Silicone) | Sil | Sil | Sil | Sil | Sil | Sil | ||||||

| Filler Material | Ag/Ni | Ag/Cu | Ag/Al | Ag/szkło | Ni/Gr | Al | ||||||

| Color | Tan | Tan | Tan | Tan | Grey | Black | ||||||

| Volume Resistivity (ohm.cm) | 5 | 5 | 1 | 1 | 5 | 20 | ||||||

| Shielding Effectiveness (dB) 10 KHz | 9 082 | 9 815 | 8 699 | 8 699 | ||||||||

| do | ||||||||||||

| 700 MHz | 1 028 | 1 056 | 9 482 | 9 599 | ||||||||

| (Min/Max) | ||||||||||||

| Shielding Effectiveness (dB) 200 KHz (H-Field) |

70 | 70 | 70 | 55 | 70 | 50 | ||||||

| No. of Contacts. | TSC REF | A +/- 0,38 mm |

B +/- 0,38 mm |

C +/- 0,20 mm |

D +/- 0,20 mm |

E +/- 0,38 mm |

r +/-0,20 mm |

R +/- 0,20 mm |

|---|---|---|---|---|---|---|---|---|

| 9 | 21 | 32,7 | 17,5 | 25 | 9,5 | 14 | 2 | 1,6 |

| 15 | 22 | 41 | 25,6 | 33,3 | 9,5 | 14 | 2 | 1,6 |

| 25 | 23 | 54,75 | 39,6 | 47,05 | 9,5 | 14 | 2 | 1,6 |

| 37 | 24 | 71,2 | 55,9 | 63,5 | 9,5 | 14 | 2 | 1,6 |

| 50 | 25 | 68,8 | 53 | 61,1 | 12 | 16,5 | 2 | 1,6 |

PA-XX-XXX

Example: PA – 3D – 021

PA – Printed

3D – Silver

021 – Shell Size

Gasket Aluminium/Silicone

| No. of Contacts. | TSC REF | A +/- 0,38 mm |

B +/- 0,38 mm |

C +/-0,08mm |

D +/- 0,18 mm |

E +/- 0,38 mm |

d +/-0,12 mm |

Rad r |

|---|---|---|---|---|---|---|---|---|

| 9 | 1 | 30,81 | 20,45 | 25 | 11,34 | 14,91 | 3,12 | 3,56 |

| 15 | 2 | 39,14 | 28,57 | 33,3 | 11,34 | 14,91 | 3,12 | 3,56 |

| 25 | 3 | 53,03 | 42,29 | 47,05 | 11,34 | 14,91 | 3,12 | 3,56 |

| 37 | 4 | 69,32 | 58,8 | 63,48 | 11,34 | 14,91 | 3,12 | 3,56 |

| 50 | 5 | 66,93 | 56,64 | 61,14 | 14,23 | 17,83 | 3,12 | 3,56 |

PB-XX-XXX

Example: PB– 3A – 001

PB – Printed

3A – Silver

021 – Shell Size,

Gasket Aluminium/Silicone

| MIL-C-38999 | |||||||

|---|---|---|---|---|---|---|---|

| Shell size | TSC REF | A+/-0,20 mm | b+/-0,20 mm | C+/-0,25 mm | d+/-0,15mm | E+/-0,20 mm | f+/-0,20 mm |

| 8 | 1 | 15,09 | 16,25 | 21,34 | 3,43 | 7 | 20,75 |

| 9+10 | 2 | 18,26 | 19,3 | 24,51 | 3,43 | 7 | 23,8 |

| 11+12 | 3 | 20,62 | 22,48 | 26,92 | 3,58 | 7,5 | 26,98 |

| 13+14 | 4 | 23,01 | 25,78 | 29,29 | 3,43 | 7 | 30,28 |

| 15+16 | 5 | 24,61 | 29,05 | 31,95 | 3,96 | 7,5 | 33,55 |

| 17+18 | 6 | 26,97 | 32,25 | 34,32 | 3,96 | 7,5 | 36,75 |

| 19+20 | 7 | 29,36 | 35,18 | 38,1 | 3,58 | 7,5 | 39,68 |

| 21+22 | 8 | 31,75 | 38,35 | 41,28 | 3,58 | 7,5 | 42,85 |

| 23+24 | 9 | 34,93 | 41,53 | 44,45 | 4,37 | 8 | 46,03 |

| 25 | 10 | 38,1 | 44,7 | 47,63 | 4,37 | 8 | 49,2 |

| MIL-C-5015/26482 | |||||||

| 8 | 11 | 15,09 | 12,95 | 22,23 | 3,96 | 7,5 | 17,45 |

| 10 | 12 | 18,26 | 16,08 | 25,4 | 3,96 | 7,5 | 20,58 |

| 12 | 13 | 20,65 | 19,3 | 27,79 | 3,58 | 7 | 23,8 |

| 14 | 14 | 23,01 | 22,48 | 30,18 | 3,96 | 7,5 | 26,98 |

| 16 | 15 | 24,61 | 25,65 | 32,54 | 3,96 | 7,5 | 30,15 |

| 18 | 16 | 26,97 | 29,08 | 34,93 | 3,96 | 7,5 | 33,58 |

| 20 | 17 | 29,36 | 32 | 38,1 | 4,37 | 8 | 36,5 |

| 22 | 18 | 31,75 | 35,18 | 41,28 | 4,37 | 8 | 39,68 |

| 24 | 19 | 34,93 | 38,35 | 44,45 | 5,16 | 9 | 42,85 |

| MIL-C-5015 | |||||||

|---|---|---|---|---|---|---|---|

| Shell size | TSC REF | A+/-0,20 mm | b+/-0,20 mm | C+/-0,25 mm | d+/-0,15mm | E+/-0,20 mm | f+/-0,20 mm |

| 28 | 20 | 39,67 | 44,7 | 50,8 | 5,16 | 9 | 49,2 |

| 32 | 21 | 44,45 | 51,05 | 57,15 | 5,56 | 9,5 | 55,55 |

| 36 | 22 | 49,23 | 57,4 | 63,5 | 5,56 | 9,5 | 61,9 |

| 40 | 23 | 55,58 | 63,75 | 69,85 | 5,56 | 9,5 | 68,25 |

| 44 | 24 | 60,33 | 70,89 | 76,2 | 5,56 | 9,5 | 75,39 |

| 48 | 25 | 66,68 | 77,24 | 82,55 | 5,56 | 9,5 | 81,74 |

| MIL-C-81511 | |||||||

| 8 | 26 | 15,09 | 14,68 | 20,62 | 3,18 | 7 | 19,18 |

| 10 | 27 | 18,26 | 17,52 | 23,8 | 3,18 | 7 | 22,02 |

| 14 | 28 | 23,01 | 24,08 | 28,58 | 3,18 | 7 | 28,58 |

| 16 | 29 | 24,61 | 27,25 | 31,75 | 3,18 | 7 | 31,75 |

| 18 | 30 | 26,97 | 30,45 | 34,11 | 3,18 | 7 | 34,95 |

| 20 | 31 | 29,36 | 33,57 | 37,26 | 3,18 | 7 | 38,07 |

| 22 | 32 | 31,75 | 36,75 | 39,67 | 3,18 | 7 | 41,25 |

| 24 | 33 | 34,93 | 39,95 | 43,26 | 3,86 | 7 | 44,45 |

| NON-MIL-STANDARD CONNECTOR GASKETS | |||||||

| 17 | 34 | 26,97 | 29 | 34,93 | 3,58 | 7,5 | 33,5 |

PD-XX-XXX

Example: PD– 3D – 001

PD – Printed

3D – Silver

001 – Shell Size

Envoyez une demande

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Nous contacter

Ajouter à la liste de souhaits

Vous devez être connecté

The technique of printing conductive elastomers is a novel and very cost effective method of producing gaskets when compared to conventional means. The printed process produces a highly selective deposit resulting in negligible wastage. Below are its major advantages:

- Cost effective versus conventional gaskets, e.g., die cut from moulded or calendered

sheet. - Printed raised beads improve stress contact in lightly loaded flanges on hardware.

- The gasket can be printed onto a conductive carrier (e.g., metal or plastic) to ease

assembly. - Component hardware (e.g., panels, covers, providing the surface the gasket is to be

located on is flat), can have the gasket printed direct onto the relevant surface, greatly

improving assembly. - Secondary environmental sealing can be incorporated into the gasket.

Comparative properties

| EcE Material Reference (Type) | 3A | 3B | 3D | 3G | 31 | 3J | 3A/1 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Elastomer Type (Sil - Silicone) | Sil | Sil | Sil | Sil | Sil | Sil | Sil | |||||

| Filler Material | Ag/Ni | Ag/Cu | Ag/Al | Ag | Ag/szkło | Ag/Gr | Al | |||||

| Color | Tan | Tan | Tan | Tan | Tan | Grey | Black | |||||

| Electrical Properties | ||||||||||||

| Volume Resistivity (ohm.cm) | 5 | 5 | 8 | 5 | 5 | 5 | 12 | |||||

| Shielding Effectiveness (dB) 10 KHz | 1 068 | 112 | 1 115 | 9 299 | 8 315 | 1 068 | 5 816 | |||||

| to | ||||||||||||

| 700 MHz | 121 | 1 283 | 1 226 | 1 007 | 9 148 | 1 218 | 6 531 | |||||

| (Min/Max) | ||||||||||||

| Shielding Effectiveness (dB) 200 KHz (H-Field) |

70 | 70 | 70 | 70 | 55 | 70 | 50 | |||||

| 100 MHz (E-Field) | 105 | 115 | 110 | 115 | 95 | 95 | 72 | |||||

| 500 MHz (E-Field) | 105 | 115 | 105 | 115 | 95 | 90 | 70 | |||||

| 2 GHz (Plane Wave) | 100 | 115 | 100 | 115 | 95 | 90 | 65 | |||||

| 10 GHz (fala płaska) | 100 | 115 | 100 | 115 | 95 | 90 | 65 | |||||

| EcE Material Reference (Type) | 3A/1 | 3B/1 | 3D/1 | 31/1 | 3J/2 | 3K/1 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Elastomer Type (Sil - Silicone) | Sil | Sil | Sil | Sil | Sil | Sil | ||||||

| Filler Material | Ag/Ni | Ag/Cu | Ag/Al | Ag/szkło | Ni/Gr | Al | ||||||

| Color | Tan | Tan | Tan | Tan | Grey | Black | ||||||

| Volume Resistivity (ohm.cm) | 5 | 5 | 1 | 1 | 5 | 20 | ||||||

| Shielding Effectiveness (dB) 10 KHz | 9 082 | 9 815 | 8 699 | 8 699 | ||||||||

| do | ||||||||||||

| 700 MHz | 1 028 | 1 056 | 9 482 | 9 599 | ||||||||

| (Min/Max) | ||||||||||||

| Shielding Effectiveness (dB) 200 KHz (H-Field) |

70 | 70 | 70 | 55 | 70 | 50 | ||||||

| No. of Contacts. | TSC REF | A +/- 0,38 mm |

B +/- 0,38 mm |

C +/- 0,20 mm |

D +/- 0,20 mm |

E +/- 0,38 mm |

r +/-0,20 mm |

R +/- 0,20 mm |

|---|---|---|---|---|---|---|---|---|

| 9 | 21 | 32,7 | 17,5 | 25 | 9,5 | 14 | 2 | 1,6 |

| 15 | 22 | 41 | 25,6 | 33,3 | 9,5 | 14 | 2 | 1,6 |

| 25 | 23 | 54,75 | 39,6 | 47,05 | 9,5 | 14 | 2 | 1,6 |

| 37 | 24 | 71,2 | 55,9 | 63,5 | 9,5 | 14 | 2 | 1,6 |

| 50 | 25 | 68,8 | 53 | 61,1 | 12 | 16,5 | 2 | 1,6 |

PA-XX-XXX

Example: PA – 3D – 021

PA – Printed

3D – Silver

021 – Shell Size

Gasket Aluminium/Silicone

| No. of Contacts. | TSC REF | A +/- 0,38 mm |

B +/- 0,38 mm |

C +/-0,08mm |

D +/- 0,18 mm |

E +/- 0,38 mm |

d +/-0,12 mm |

Rad r |

|---|---|---|---|---|---|---|---|---|

| 9 | 1 | 30,81 | 20,45 | 25 | 11,34 | 14,91 | 3,12 | 3,56 |

| 15 | 2 | 39,14 | 28,57 | 33,3 | 11,34 | 14,91 | 3,12 | 3,56 |

| 25 | 3 | 53,03 | 42,29 | 47,05 | 11,34 | 14,91 | 3,12 | 3,56 |

| 37 | 4 | 69,32 | 58,8 | 63,48 | 11,34 | 14,91 | 3,12 | 3,56 |

| 50 | 5 | 66,93 | 56,64 | 61,14 | 14,23 | 17,83 | 3,12 | 3,56 |

PB-XX-XXX

Example: PB– 3A – 001

PB – Printed

3A – Silver

021 – Shell Size,

Gasket Aluminium/Silicone

| MIL-C-38999 | |||||||

|---|---|---|---|---|---|---|---|

| Shell size | TSC REF | A+/-0,20 mm | b+/-0,20 mm | C+/-0,25 mm | d+/-0,15mm | E+/-0,20 mm | f+/-0,20 mm |

| 8 | 1 | 15,09 | 16,25 | 21,34 | 3,43 | 7 | 20,75 |

| 9+10 | 2 | 18,26 | 19,3 | 24,51 | 3,43 | 7 | 23,8 |

| 11+12 | 3 | 20,62 | 22,48 | 26,92 | 3,58 | 7,5 | 26,98 |

| 13+14 | 4 | 23,01 | 25,78 | 29,29 | 3,43 | 7 | 30,28 |

| 15+16 | 5 | 24,61 | 29,05 | 31,95 | 3,96 | 7,5 | 33,55 |

| 17+18 | 6 | 26,97 | 32,25 | 34,32 | 3,96 | 7,5 | 36,75 |

| 19+20 | 7 | 29,36 | 35,18 | 38,1 | 3,58 | 7,5 | 39,68 |

| 21+22 | 8 | 31,75 | 38,35 | 41,28 | 3,58 | 7,5 | 42,85 |

| 23+24 | 9 | 34,93 | 41,53 | 44,45 | 4,37 | 8 | 46,03 |

| 25 | 10 | 38,1 | 44,7 | 47,63 | 4,37 | 8 | 49,2 |

| MIL-C-5015/26482 | |||||||

| 8 | 11 | 15,09 | 12,95 | 22,23 | 3,96 | 7,5 | 17,45 |

| 10 | 12 | 18,26 | 16,08 | 25,4 | 3,96 | 7,5 | 20,58 |

| 12 | 13 | 20,65 | 19,3 | 27,79 | 3,58 | 7 | 23,8 |

| 14 | 14 | 23,01 | 22,48 | 30,18 | 3,96 | 7,5 | 26,98 |

| 16 | 15 | 24,61 | 25,65 | 32,54 | 3,96 | 7,5 | 30,15 |

| 18 | 16 | 26,97 | 29,08 | 34,93 | 3,96 | 7,5 | 33,58 |

| 20 | 17 | 29,36 | 32 | 38,1 | 4,37 | 8 | 36,5 |

| 22 | 18 | 31,75 | 35,18 | 41,28 | 4,37 | 8 | 39,68 |

| 24 | 19 | 34,93 | 38,35 | 44,45 | 5,16 | 9 | 42,85 |

| MIL-C-5015 | |||||||

|---|---|---|---|---|---|---|---|

| Shell size | TSC REF | A+/-0,20 mm | b+/-0,20 mm | C+/-0,25 mm | d+/-0,15mm | E+/-0,20 mm | f+/-0,20 mm |

| 28 | 20 | 39,67 | 44,7 | 50,8 | 5,16 | 9 | 49,2 |

| 32 | 21 | 44,45 | 51,05 | 57,15 | 5,56 | 9,5 | 55,55 |

| 36 | 22 | 49,23 | 57,4 | 63,5 | 5,56 | 9,5 | 61,9 |

| 40 | 23 | 55,58 | 63,75 | 69,85 | 5,56 | 9,5 | 68,25 |

| 44 | 24 | 60,33 | 70,89 | 76,2 | 5,56 | 9,5 | 75,39 |

| 48 | 25 | 66,68 | 77,24 | 82,55 | 5,56 | 9,5 | 81,74 |

| MIL-C-81511 | |||||||

| 8 | 26 | 15,09 | 14,68 | 20,62 | 3,18 | 7 | 19,18 |

| 10 | 27 | 18,26 | 17,52 | 23,8 | 3,18 | 7 | 22,02 |

| 14 | 28 | 23,01 | 24,08 | 28,58 | 3,18 | 7 | 28,58 |

| 16 | 29 | 24,61 | 27,25 | 31,75 | 3,18 | 7 | 31,75 |

| 18 | 30 | 26,97 | 30,45 | 34,11 | 3,18 | 7 | 34,95 |

| 20 | 31 | 29,36 | 33,57 | 37,26 | 3,18 | 7 | 38,07 |

| 22 | 32 | 31,75 | 36,75 | 39,67 | 3,18 | 7 | 41,25 |

| 24 | 33 | 34,93 | 39,95 | 43,26 | 3,86 | 7 | 44,45 |

| NON-MIL-STANDARD CONNECTOR GASKETS | |||||||

| 17 | 34 | 26,97 | 29 | 34,93 | 3,58 | 7,5 | 33,5 |

PD-XX-XXX

Example: PD– 3D – 001

PD – Printed

3D – Silver

001 – Shell Size

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé