Vous devez être connecté

Category

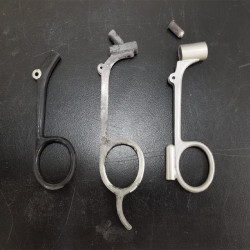

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

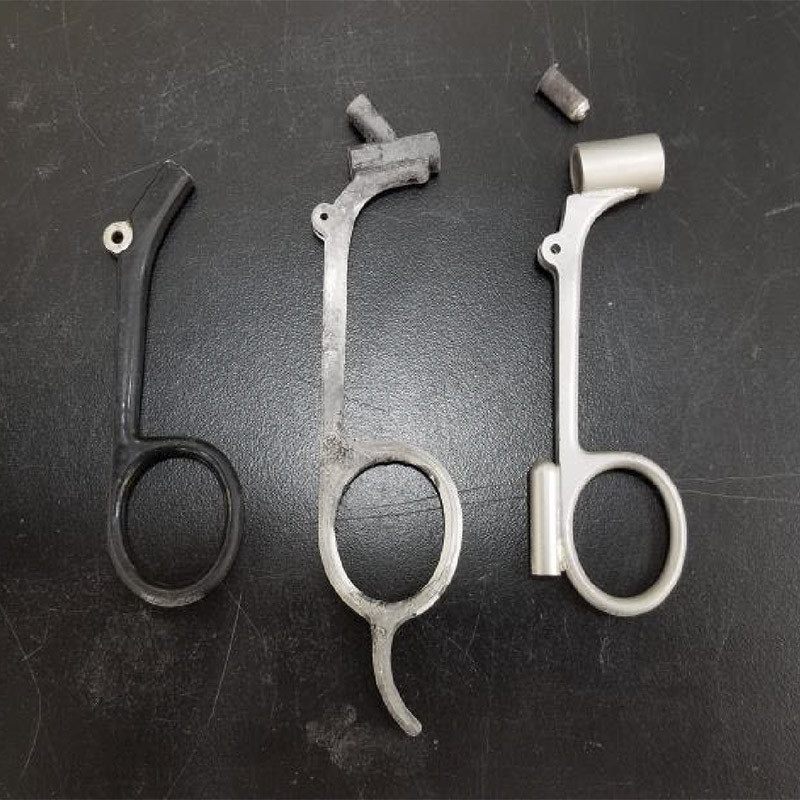

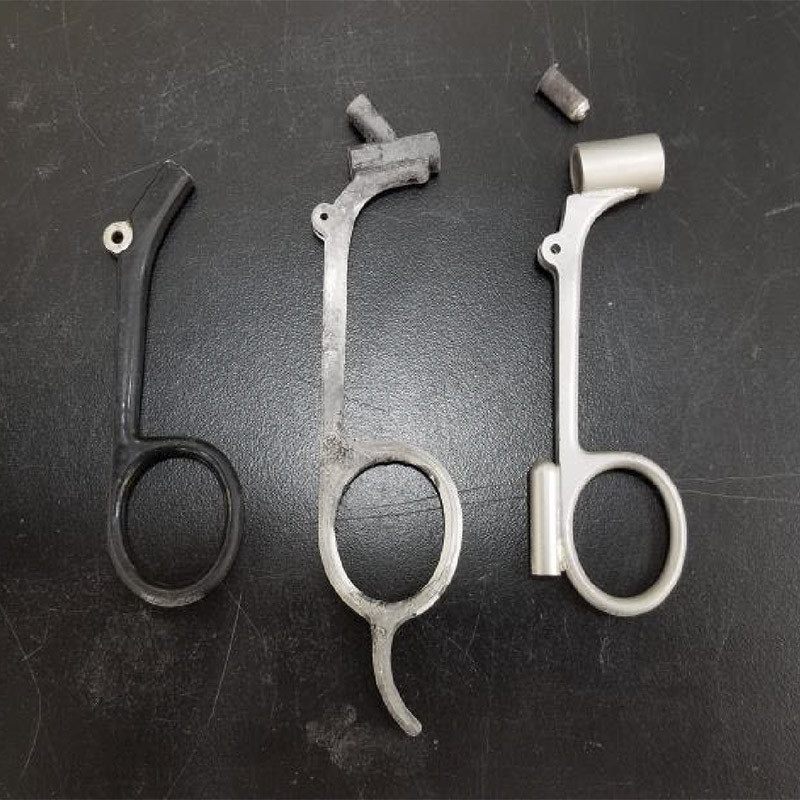

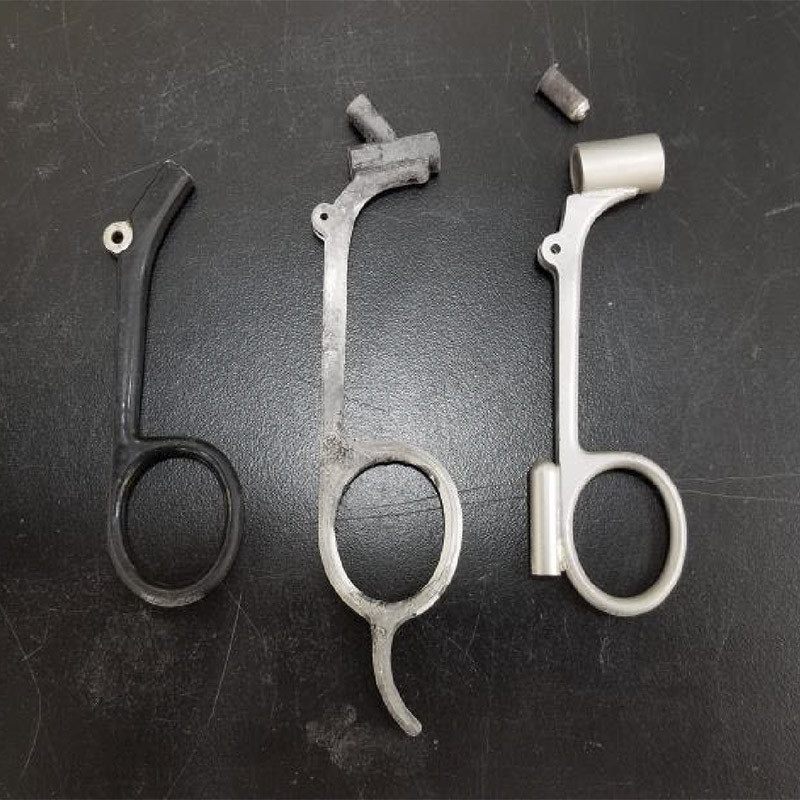

Objective: To heat surgical tools to burn-off the nylon coating; the client had been using a torch for this application.

Equipment: Ambrell EASYHEAT® 1.2 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Frequency: 251 kHz

Material: Magnetic steel surgical tools

Testing:

Benefits:

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Objective: To heat surgical tools to burn-off the nylon coating; the client had been using a torch for this application.

Equipment: Ambrell EASYHEAT® 1.2 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Frequency: 251 kHz

Material: Magnetic steel surgical tools

Testing:

Benefits:

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé