Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

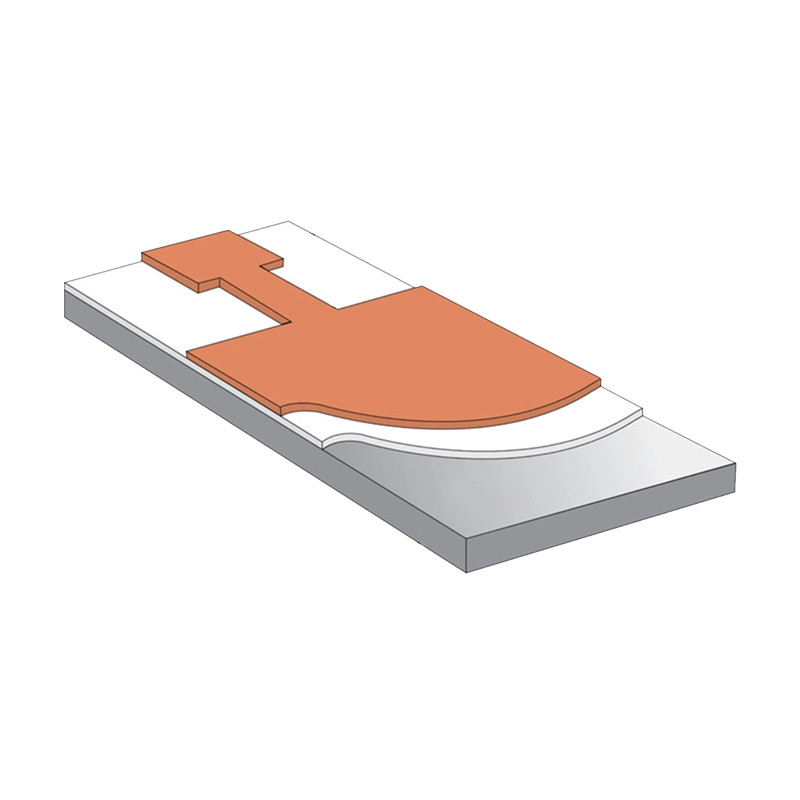

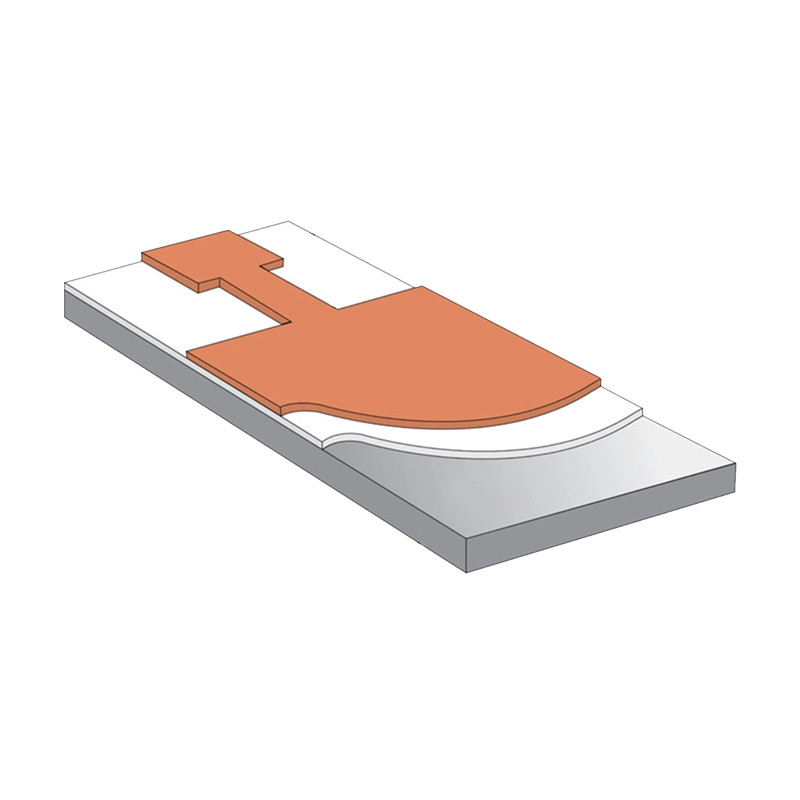

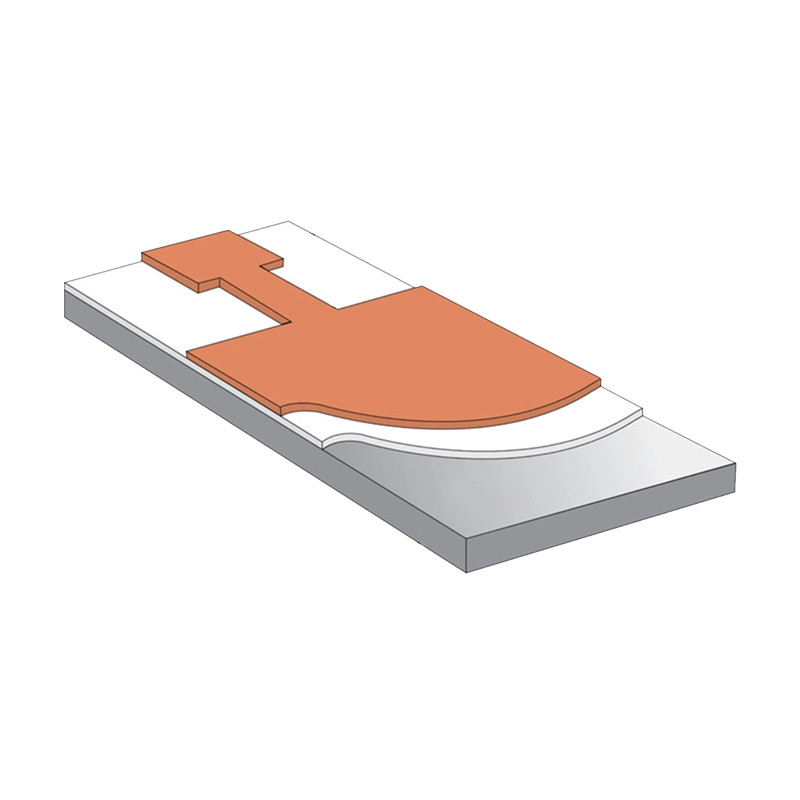

Thermal Clad is a versatile substrate allowing circuit boards to be configured for shapes, bends and multiple thicknesses. In this motor control application, the dielectric has been selectively removed and the metal formed with three-dimensional features.

Additional Thermal Clad benefits:

• Increased power density

• Extend the life of dies

• Improved product thermal and mechanical performance

• Better use of surface mount technology

Anatomy of a Thermal Clad Board:

1. Base layer Copper 0,51 - 4,83 mm oa Aluminium 0,51 - 3,18 mm.

2. Dielectric layer – HPL, HT, LM, MP.

3. Circuit layer – 35 um – 350 um.

Parameters:

|

Type

|

Thickness

(10-3in/10-6m) |

Impedance

(oC/W) |

Conductivity

(W/m-k) |

Operating

(VAC) |

Breakdown

(kVAC) |

HT-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.0

|

HT-07006 |

6/150

|

0.70

|

2.2

|

960

|

11.0

|

LTI-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.5

|

LTI-06005 |

5/125

|

0.60

|

2.2

|

480

|

9.5

|

MP-06503 |

3/75

|

0.65

|

1.3

|

120

|

8.5

|

Light output of the same LED die on different circuit board materials at a maintained die temperature of 80ºC.

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Thermal Clad is a versatile substrate allowing circuit boards to be configured for shapes, bends and multiple thicknesses. In this motor control application, the dielectric has been selectively removed and the metal formed with three-dimensional features.

Additional Thermal Clad benefits:

• Increased power density

• Extend the life of dies

• Improved product thermal and mechanical performance

• Better use of surface mount technology

Anatomy of a Thermal Clad Board:

1. Base layer Copper 0,51 - 4,83 mm oa Aluminium 0,51 - 3,18 mm.

2. Dielectric layer – HPL, HT, LM, MP.

3. Circuit layer – 35 um – 350 um.

Parameters:

|

Type

|

Thickness

(10-3in/10-6m) |

Impedance

(oC/W) |

Conductivity

(W/m-k) |

Operating

(VAC) |

Breakdown

(kVAC) |

HT-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.0

|

HT-07006 |

6/150

|

0.70

|

2.2

|

960

|

11.0

|

LTI-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.5

|

LTI-06005 |

5/125

|

0.60

|

2.2

|

480

|

9.5

|

MP-06503 |

3/75

|

0.65

|

1.3

|

120

|

8.5

|

Light output of the same LED die on different circuit board materials at a maintained die temperature of 80ºC.

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé