Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

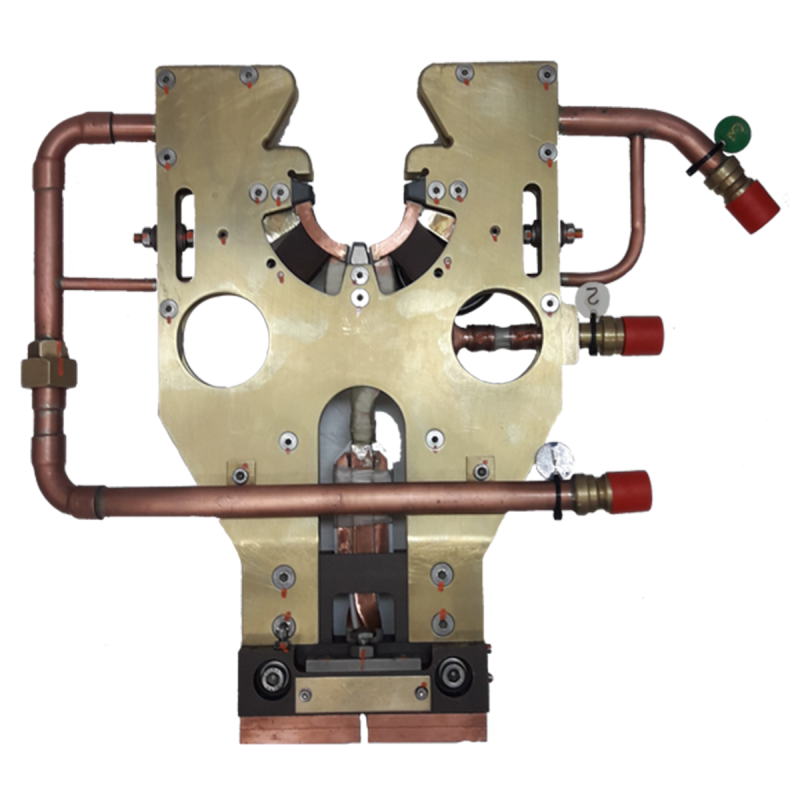

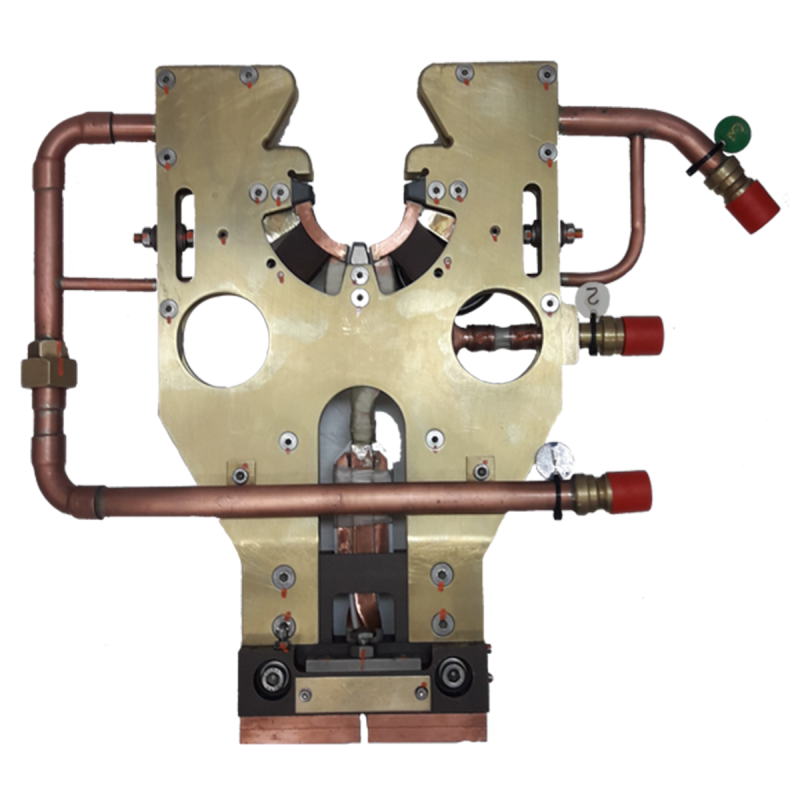

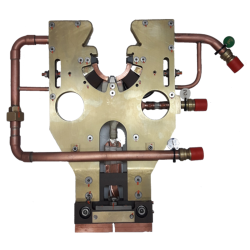

The modernization of the inductor is the introduction of changes in its design aimed at:

Example:

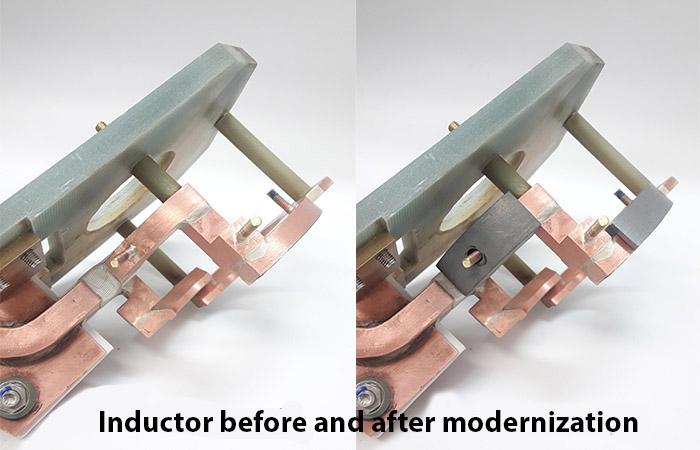

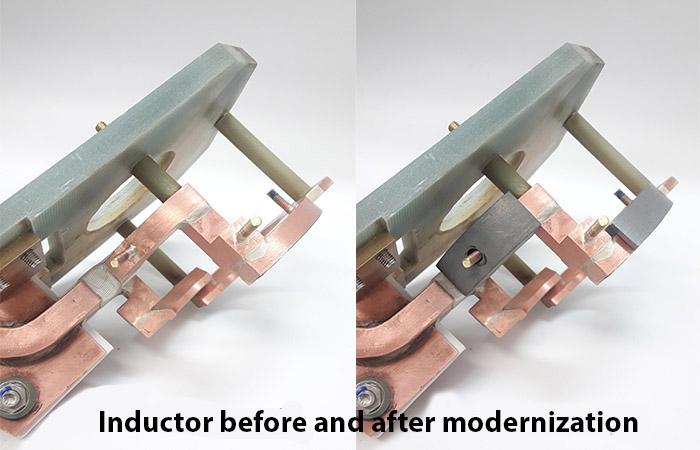

The change in the shape of the inductor head and the use of magnetic field concentrators allowed to increase the precision and reduce heating in non-hardened zones, increase the efficiency of the process by more precisely focusing energy to the hardened area, reducing the heating time while maintaining the same value of power absorbed.

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

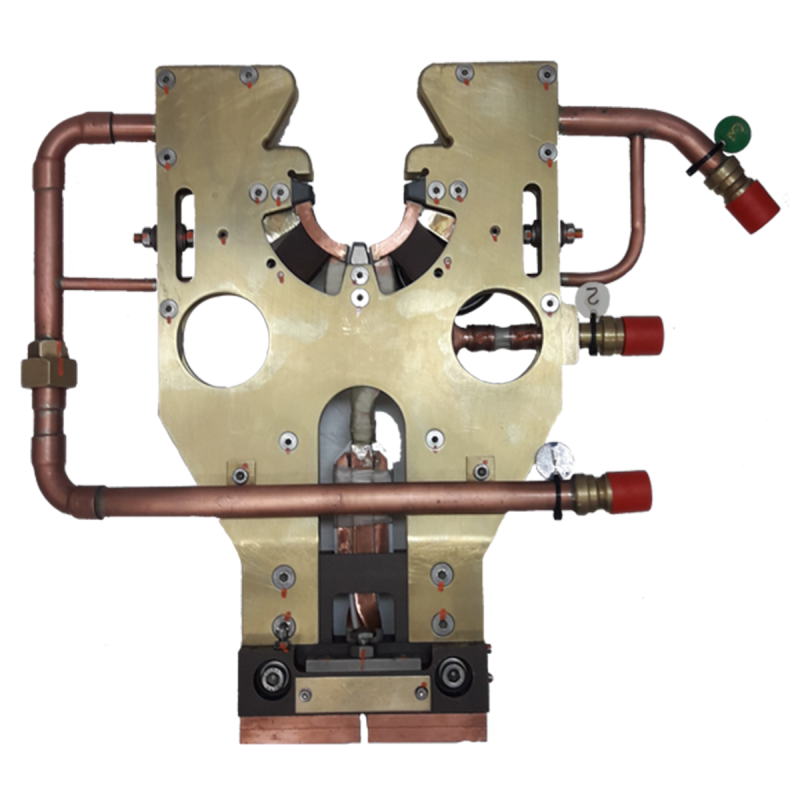

The modernization of the inductor is the introduction of changes in its design aimed at:

Example:

The change in the shape of the inductor head and the use of magnetic field concentrators allowed to increase the precision and reduce heating in non-hardened zones, increase the efficiency of the process by more precisely focusing energy to the hardened area, reducing the heating time while maintaining the same value of power absorbed.

The use of induction heating in the manufacture of industrial equipment

The use of induction heating in the manufacture of industrial equipment

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé