Vous devez être connecté

Category

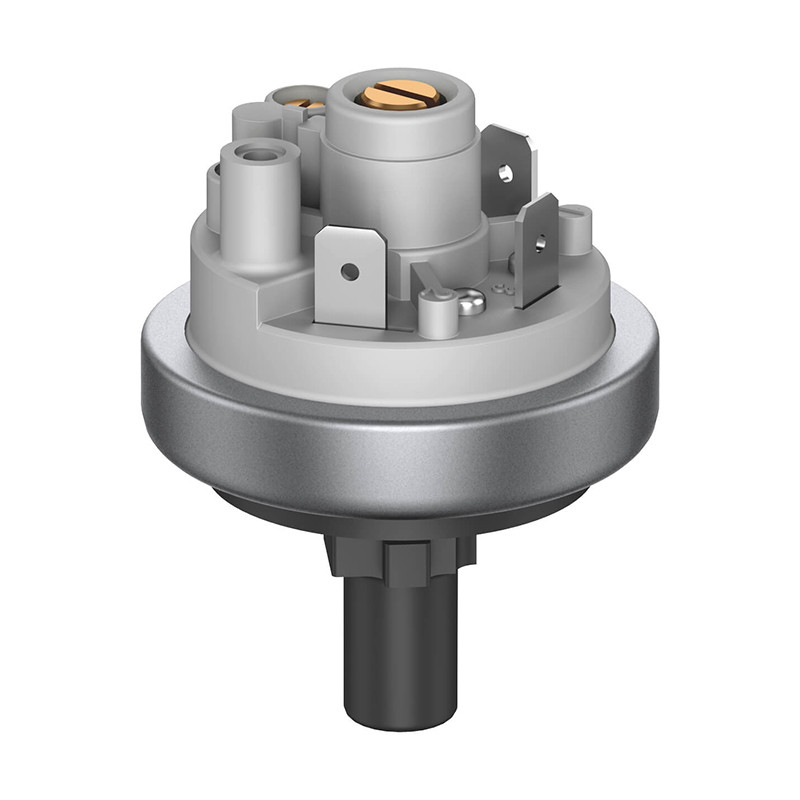

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

Zone 0

Factory-set pressure switch monitoring overpressure, vacuum or differential pressure of liquid and gaseous – also aggressive – media.

Pressure setting and switching differential are factory-set by the manufacturer.

Specifications:

| Medium | Air, (non-)combustible and aggressive gases and vapours |

| Temperature ranges: | |

| Medium and ambient temperature | -20OC +85OC |

| Storage temperature | -40OC +85OC |

| Trip pressure ranges: | |

| Overpressure | 5 to 200 mbar (min. measuring range |

| 1 to 12 bar (max. measuring range) | |

| Vacuum | -5 to -200 mbar (min. measuring range) |

| -200 to -900 mbar (max. measuring range) | |

| Differential pressure | 5 ... 50 mbar |

| Max. working overpressure | 0.1 to 25 bar/-1 bar (refer to table |

| Switching differential | 2.5 to 1,500 mbar; depending on pressure range (refer to table) |

| Trip pressure tolerance | ±10% from setpoint |

| Materials | |

| Tube connection | 5 / 6.5 and 10 mm, PA / PPS |

| Threaded connections | M10x1 / G1/8 to G1/2 |

| PA/PVDF/stainless steel/brass | |

| Diaphragm | depending on medium; NBR, silicone, FKM (Viton ® ), EPDM, for 901.30 silicone (other materials on request). |

| Weight | 24 VDC/100 mA; 30 VDC/45 mA |

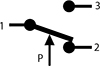

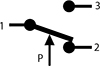

| Electrical rating | 24VDC/100mA; 30VDC/45mA |

| Electrical connection | AMP flat plug, 6.3 mm x 0.8 mm, in accordance with DIN 46244, or push-on screw terminals |

| Cable conduit | M16x1.5, with integrated cable strain relief |

| Protection category | IP 54 (with cover 6371) |

| Mechanical working life | over 106 switching operations |

| Reducing nozzles | diameter optionally 0.3/0.5/0.8 mm |

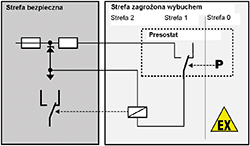

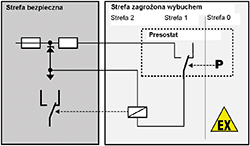

ATEX

| EC type examination | BVS 06 ATEX E 141X |

| Device category | I 1/2G or II 2G |

| Ignition protection type | EX ia IIBT4 or EX ia IICT4 |

| CE conformity | ATEX Directive 94/9/EC |

| RoHS-Directive 2002/95/EC | |

| Other approvals | type examination by TÜV Südwest and DVGW |

| for 901.1x EX, 901.30 EX, 901.41 EX, 901.51 EX | only for 901.2x EX |

|

|

| Type | Tube connections | Threaded connections | |||||

|---|---|---|---|---|---|---|---|

| 5,0 mm | 6,5 mm | 10,0 mm | M10x1 | G1/8 | G1/4 | G1/2 | |

901.1x EX |

PA | PA PPS | PA PPS | PA, PVDF, MS, V2A | PA, PVDF, MS, V2A | PVDF, MS, V2A | MS |

901.2x EX |

PA | PA PPS | PA PPS | PA, PVDF, MS, V2A | PA, PVDF, MS, V2A | MS, V2A | MS |

901.30 EX |

PA | ||||||

901.41 EX |

PA PPS | PA PPS | PA, PVDF, MS, V2A | PA, PVDF, MS, V2A | MS, V2A | MS | |

901.51 EX |

MS | MS, V2A | MS, V2A | ||||

PA = polyamide, PVDF = polyvinyldifluoride, PPS = polyphenylensulfide, MS = brass

| Type | Factory-set trip pressure selectable |

Standard switching differential | Tolerance band in % of trip pressure |

Maximum positive working pressure |

Maximum negative working pressure |

||

|---|---|---|---|---|---|---|---|

| between | and | lower end of range | upper end of range | ||||

901.1x EX |

5 | 200 mbar | 2,5 mbar | 50 mbar | 10% | 0,5 / 4 bar | -/ -1 bar |

| 200 | 1000 mbar | 50 mbar | 150 mbar | 10% | 1 / 4 bar | -/ -1 bar | |

901.41 EX |

500 | 3000 mbar | 200 mbar | 600 mbar | 10% | 10 bar | -1 bar |

901.51 EX |

1,0 bar | 12 bar | 0,2 bar | 1,5 bar | 10% | 25 bar | -1 bar |

| Type | Factory-set trip pressure selectable |

Standard switching differential | Tolerance band in % of trip pressure |

Maximum positive working pressure |

Maximum negative working pressure |

||

|---|---|---|---|---|---|---|---|

| between | and | lower end of range | upper end of range | ||||

901.2x EX |

-5 | -200 mbar | 2,5 mbar | 50 mbar | 10% | 0,5 / 4 bar | -1 bar |

| -200 | -900 mbar | 50 mbar | 150 mbar | 10% | 1 / 4 bar | -1 bar | |

| Type | Factory-set trip pressure selectable |

Standard switching differential | Tolerance band in % of trip pressure |

Maximum positive working pressure |

Maximum negative working pressure |

||

|---|---|---|---|---|---|---|---|

| between | and | lower end of range | upper end of range | ||||

901.30 |

5 mbar | 50 mbar | 2,5 mbar | 25 mbar | 10% | 100 mbar | -100 mbar |

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Zone 0

Factory-set pressure switch monitoring overpressure, vacuum or differential pressure of liquid and gaseous – also aggressive – media.

Pressure setting and switching differential are factory-set by the manufacturer.

Specifications:

| Medium | Air, (non-)combustible and aggressive gases and vapours |

| Temperature ranges: | |

| Medium and ambient temperature | -20OC +85OC |

| Storage temperature | -40OC +85OC |

| Trip pressure ranges: | |

| Overpressure | 5 to 200 mbar (min. measuring range |

| 1 to 12 bar (max. measuring range) | |

| Vacuum | -5 to -200 mbar (min. measuring range) |

| -200 to -900 mbar (max. measuring range) | |

| Differential pressure | 5 ... 50 mbar |

| Max. working overpressure | 0.1 to 25 bar/-1 bar (refer to table |

| Switching differential | 2.5 to 1,500 mbar; depending on pressure range (refer to table) |

| Trip pressure tolerance | ±10% from setpoint |

| Materials | |

| Tube connection | 5 / 6.5 and 10 mm, PA / PPS |

| Threaded connections | M10x1 / G1/8 to G1/2 |

| PA/PVDF/stainless steel/brass | |

| Diaphragm | depending on medium; NBR, silicone, FKM (Viton ® ), EPDM, for 901.30 silicone (other materials on request). |

| Weight | 24 VDC/100 mA; 30 VDC/45 mA |

| Electrical rating | 24VDC/100mA; 30VDC/45mA |

| Electrical connection | AMP flat plug, 6.3 mm x 0.8 mm, in accordance with DIN 46244, or push-on screw terminals |

| Cable conduit | M16x1.5, with integrated cable strain relief |

| Protection category | IP 54 (with cover 6371) |

| Mechanical working life | over 106 switching operations |

| Reducing nozzles | diameter optionally 0.3/0.5/0.8 mm |

ATEX

| EC type examination | BVS 06 ATEX E 141X |

| Device category | I 1/2G or II 2G |

| Ignition protection type | EX ia IIBT4 or EX ia IICT4 |

| CE conformity | ATEX Directive 94/9/EC |

| RoHS-Directive 2002/95/EC | |

| Other approvals | type examination by TÜV Südwest and DVGW |

| for 901.1x EX, 901.30 EX, 901.41 EX, 901.51 EX | only for 901.2x EX |

|

|

| Type | Tube connections | Threaded connections | |||||

|---|---|---|---|---|---|---|---|

| 5,0 mm | 6,5 mm | 10,0 mm | M10x1 | G1/8 | G1/4 | G1/2 | |

901.1x EX |

PA | PA PPS | PA PPS | PA, PVDF, MS, V2A | PA, PVDF, MS, V2A | PVDF, MS, V2A | MS |

901.2x EX |

PA | PA PPS | PA PPS | PA, PVDF, MS, V2A | PA, PVDF, MS, V2A | MS, V2A | MS |

901.30 EX |

PA | ||||||

901.41 EX |

PA PPS | PA PPS | PA, PVDF, MS, V2A | PA, PVDF, MS, V2A | MS, V2A | MS | |

901.51 EX |

MS | MS, V2A | MS, V2A | ||||

PA = polyamide, PVDF = polyvinyldifluoride, PPS = polyphenylensulfide, MS = brass

| Type | Factory-set trip pressure selectable |

Standard switching differential | Tolerance band in % of trip pressure |

Maximum positive working pressure |

Maximum negative working pressure |

||

|---|---|---|---|---|---|---|---|

| between | and | lower end of range | upper end of range | ||||

901.1x EX |

5 | 200 mbar | 2,5 mbar | 50 mbar | 10% | 0,5 / 4 bar | -/ -1 bar |

| 200 | 1000 mbar | 50 mbar | 150 mbar | 10% | 1 / 4 bar | -/ -1 bar | |

901.41 EX |

500 | 3000 mbar | 200 mbar | 600 mbar | 10% | 10 bar | -1 bar |

901.51 EX |

1,0 bar | 12 bar | 0,2 bar | 1,5 bar | 10% | 25 bar | -1 bar |

| Type | Factory-set trip pressure selectable |

Standard switching differential | Tolerance band in % of trip pressure |

Maximum positive working pressure |

Maximum negative working pressure |

||

|---|---|---|---|---|---|---|---|

| between | and | lower end of range | upper end of range | ||||

901.2x EX |

-5 | -200 mbar | 2,5 mbar | 50 mbar | 10% | 0,5 / 4 bar | -1 bar |

| -200 | -900 mbar | 50 mbar | 150 mbar | 10% | 1 / 4 bar | -1 bar | |

| Type | Factory-set trip pressure selectable |

Standard switching differential | Tolerance band in % of trip pressure |

Maximum positive working pressure |

Maximum negative working pressure |

||

|---|---|---|---|---|---|---|---|

| between | and | lower end of range | upper end of range | ||||

901.30 |

5 mbar | 50 mbar | 2,5 mbar | 25 mbar | 10% | 100 mbar | -100 mbar |

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé