Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

Characteristics

• Continuous operating temperatures: -60 °C to +180 °C

• Good resistance to thermal shock and UV

• Excellent mechanical strength.

• Rated voltage: 1.1 kV

• Test voltage: 3.5 kV

Standard products

• Standard insulation colour: white.

• Standard reinforcing braid colour: yellow.

• Standard marking: OMERIN - SILICOUL 1.1 KV - {cross-section}

No printing on sections 1.5 mm2 to 6 mm2

Approvals - standards

• Smoke classification F1 as per NF F 16-101.

• Bureau VERITAS approval certificates: compliance with the tests described as per standards

IEC 60092-350/353/360, IEC 60228,

IEC 60331-11/21, IEC 60332-1-1/2,

EC 60332-3-22 and IEC 60754-2.

• Lloyd’s Register approval certificates: compliance with the tests described as per standards

IEC 60228, IEC 60092-350/353/360,

IEC 60754-2, IEC 60332-1-1/2,

IEC 60332-3-22 category A and IEC 60331-11/21.

Applications

• Cabling for rotating machines: motors, alternators, generators

• Cabling for static machines: transformers, inductors, inverters, choppers.

• Shipbuilding and railway construction.

• Power cabinets.

Options

• Extra-flexible tin-plated copper core - class 6 as per IEC 60228: contact us.

• Flexible or extra-flexible bare copper, silver-plated or nickel-plated copper core – class 5 or 6 as per IEC 60228: contact us

• Without reinforcing braid (ref. SILICOUL® ST 1.1 KV): contact us.

• Varnished synthetic fibre reinforcing braid (ref. SILICOUL® RI 1.1 KV): contact us.

• Very high temperature fibre reinforcing braid: contact us.

• Outer flexible armour: > Galvanised steel braid (ref. SILICOUL® BG 1.1 KV): contact us. > Stainless steel braid (ref. SILICOUL® BI 1.1 KV): contact us

• Multi-conductor cable made up of an assembly of several single conductor cables SILICOUL® 1.1 KV: contact us.

• Other markings: contact us.

• Other colours: contact us.

• Other nominal cross-sections: contact us

• Other options and/or combinations of the options outlined above: contact us.

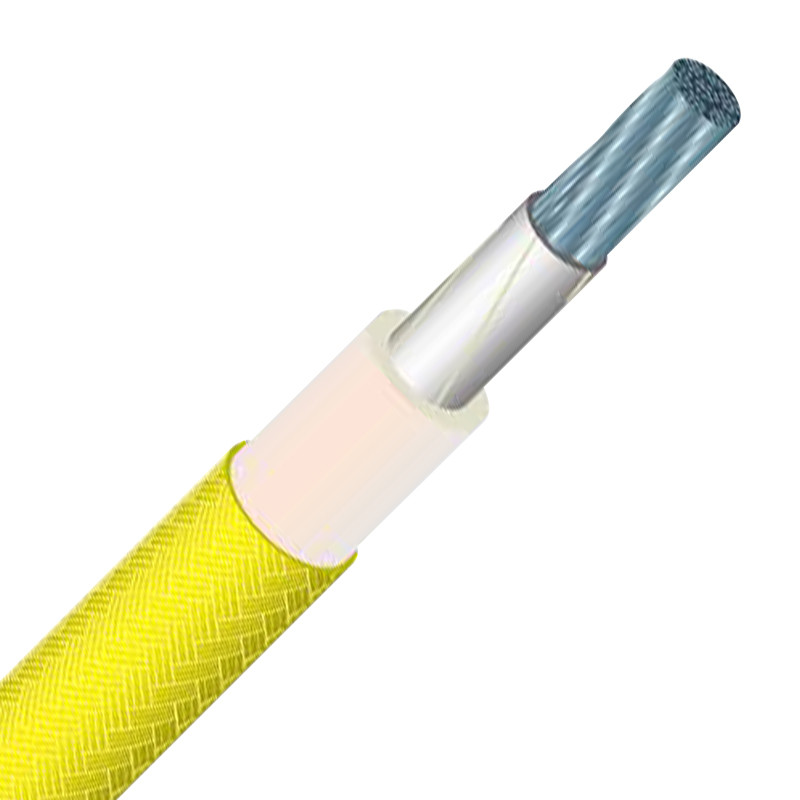

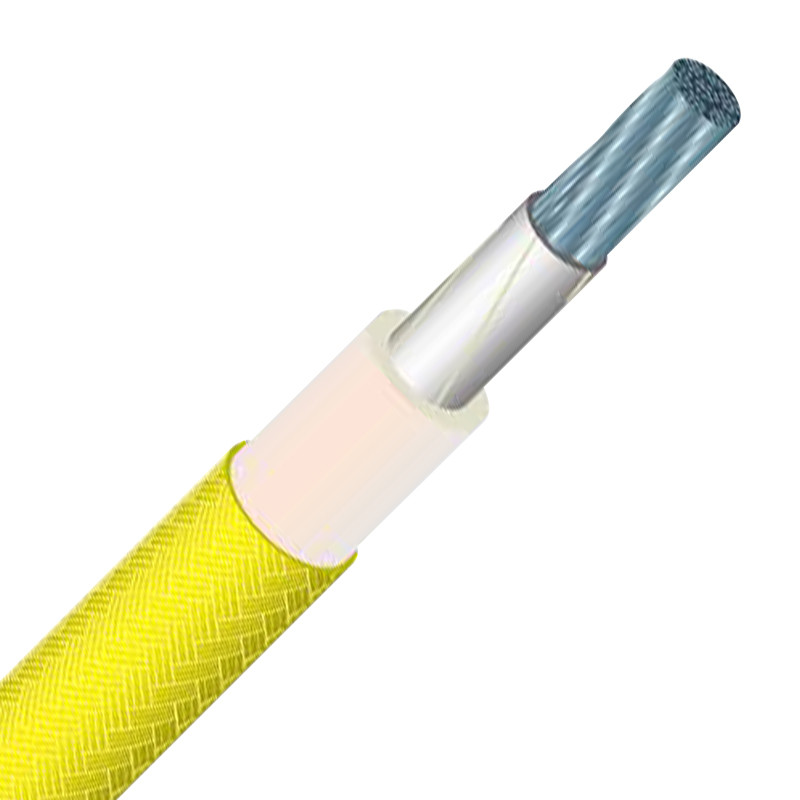

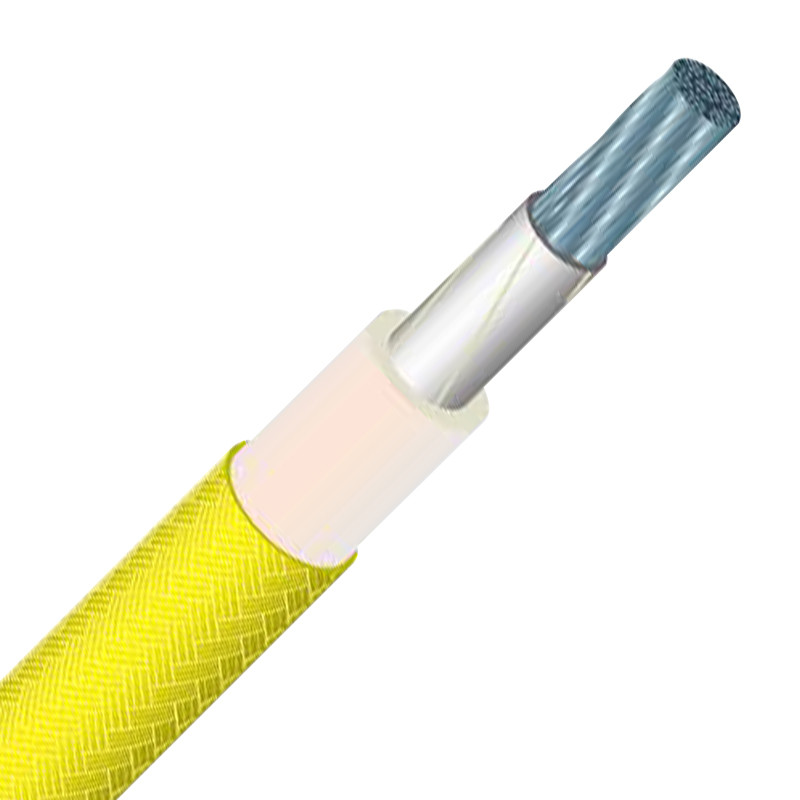

1 • Flexible tin-plated copper core - class 5 as per IEC 60228.

2 • Optional separating tape.

3 • Insulation: Silicone rubber

4 • Reinforcement: Coated synthetic fibre braid.

| Nominal cross-section [mm 2] |

Nominal stranding | Maximum linear resistance at 20 °C (Ω/km) | Nominal diameter [mm] |

Approximate linear weight [kg/km] |

|---|---|---|---|---|

| 1.5 | 30 x 0.25 | 13.7 | 3.8 | 23.5 |

| 2.5 | 50 x 0.25 | 8.21 | 4.3 | 34.0 |

| 4 | 56 x 0.30 | 5.09 | 4.9 | 48.9 |

| 6 | 84 x 0.30 | 3.39 | 6.0 | 71.7 |

| 10 | 80 x 0.40 | 1.95 | 7.2 | 117 |

| 16 | 126 x 0.40 | 1.24 | 8.6 | 174 |

| 25 | 196 x 0.40 | 0.795 | 10.4 | 268 |

| 35 | 276 x 0.40 | 0.565 | 1 1.9 | 360 |

| 50 | 396 x 0.40 | 0.393 | 14.1 | 512 |

| 70 | 360 x 0.50 | 0.277 | 15.9 | 686 |

| 95 | 485 x 0.50 | 0.210 | 18.2 | 914 |

| 120 | 608 x 0.50 | 0.164 | 20.7 | 1174 |

| 150 | 756 x 0.50 | 0.132 | 23.2 | 1457 |

| 185 | 944 x 0.50 | 0.108 | 25.2 | 1819 |

| 240 | 1221 x 0.50 | 0.0817 | 29.2 | 2448 |

| 300 | 1525 x 0.50 | 0.0654 | 31.6 | 2992 |

| 400 | 2037 x 0.50 | 0.0495 | 34.6 | 3837 |

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Characteristics

• Continuous operating temperatures: -60 °C to +180 °C

• Good resistance to thermal shock and UV

• Excellent mechanical strength.

• Rated voltage: 1.1 kV

• Test voltage: 3.5 kV

Standard products

• Standard insulation colour: white.

• Standard reinforcing braid colour: yellow.

• Standard marking: OMERIN - SILICOUL 1.1 KV - {cross-section}

No printing on sections 1.5 mm2 to 6 mm2

Approvals - standards

• Smoke classification F1 as per NF F 16-101.

• Bureau VERITAS approval certificates: compliance with the tests described as per standards

IEC 60092-350/353/360, IEC 60228,

IEC 60331-11/21, IEC 60332-1-1/2,

EC 60332-3-22 and IEC 60754-2.

• Lloyd’s Register approval certificates: compliance with the tests described as per standards

IEC 60228, IEC 60092-350/353/360,

IEC 60754-2, IEC 60332-1-1/2,

IEC 60332-3-22 category A and IEC 60331-11/21.

Applications

• Cabling for rotating machines: motors, alternators, generators

• Cabling for static machines: transformers, inductors, inverters, choppers.

• Shipbuilding and railway construction.

• Power cabinets.

Options

• Extra-flexible tin-plated copper core - class 6 as per IEC 60228: contact us.

• Flexible or extra-flexible bare copper, silver-plated or nickel-plated copper core – class 5 or 6 as per IEC 60228: contact us

• Without reinforcing braid (ref. SILICOUL® ST 1.1 KV): contact us.

• Varnished synthetic fibre reinforcing braid (ref. SILICOUL® RI 1.1 KV): contact us.

• Very high temperature fibre reinforcing braid: contact us.

• Outer flexible armour: > Galvanised steel braid (ref. SILICOUL® BG 1.1 KV): contact us. > Stainless steel braid (ref. SILICOUL® BI 1.1 KV): contact us

• Multi-conductor cable made up of an assembly of several single conductor cables SILICOUL® 1.1 KV: contact us.

• Other markings: contact us.

• Other colours: contact us.

• Other nominal cross-sections: contact us

• Other options and/or combinations of the options outlined above: contact us.

1 • Flexible tin-plated copper core - class 5 as per IEC 60228.

2 • Optional separating tape.

3 • Insulation: Silicone rubber

4 • Reinforcement: Coated synthetic fibre braid.

| Nominal cross-section [mm 2] |

Nominal stranding | Maximum linear resistance at 20 °C (Ω/km) | Nominal diameter [mm] |

Approximate linear weight [kg/km] |

|---|---|---|---|---|

| 1.5 | 30 x 0.25 | 13.7 | 3.8 | 23.5 |

| 2.5 | 50 x 0.25 | 8.21 | 4.3 | 34.0 |

| 4 | 56 x 0.30 | 5.09 | 4.9 | 48.9 |

| 6 | 84 x 0.30 | 3.39 | 6.0 | 71.7 |

| 10 | 80 x 0.40 | 1.95 | 7.2 | 117 |

| 16 | 126 x 0.40 | 1.24 | 8.6 | 174 |

| 25 | 196 x 0.40 | 0.795 | 10.4 | 268 |

| 35 | 276 x 0.40 | 0.565 | 1 1.9 | 360 |

| 50 | 396 x 0.40 | 0.393 | 14.1 | 512 |

| 70 | 360 x 0.50 | 0.277 | 15.9 | 686 |

| 95 | 485 x 0.50 | 0.210 | 18.2 | 914 |

| 120 | 608 x 0.50 | 0.164 | 20.7 | 1174 |

| 150 | 756 x 0.50 | 0.132 | 23.2 | 1457 |

| 185 | 944 x 0.50 | 0.108 | 25.2 | 1819 |

| 240 | 1221 x 0.50 | 0.0817 | 29.2 | 2448 |

| 300 | 1525 x 0.50 | 0.0654 | 31.6 | 2992 |

| 400 | 2037 x 0.50 | 0.0495 | 34.6 | 3837 |

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé