Vous devez être connecté

Category

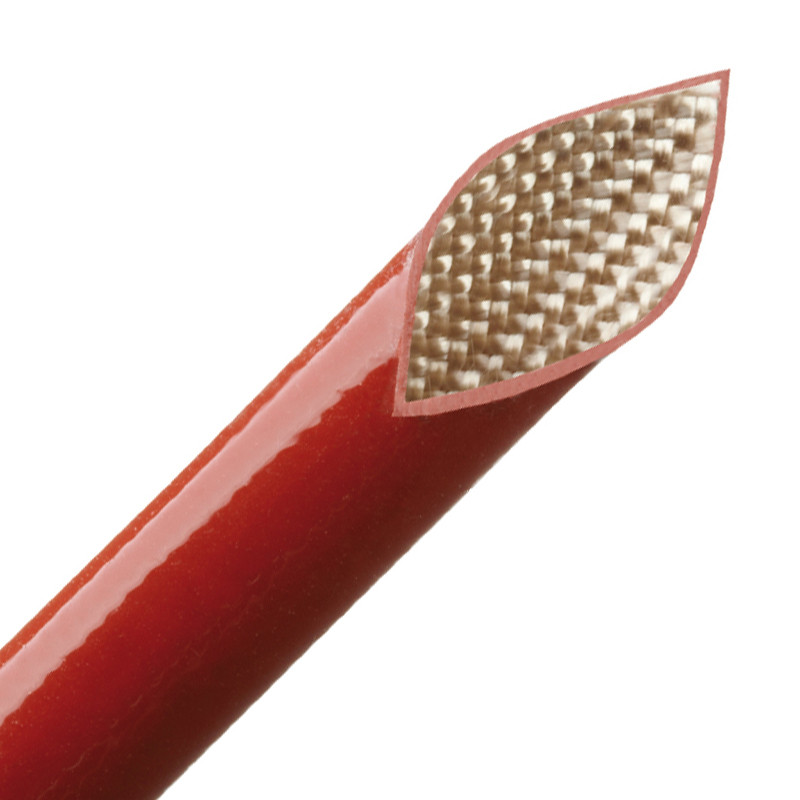

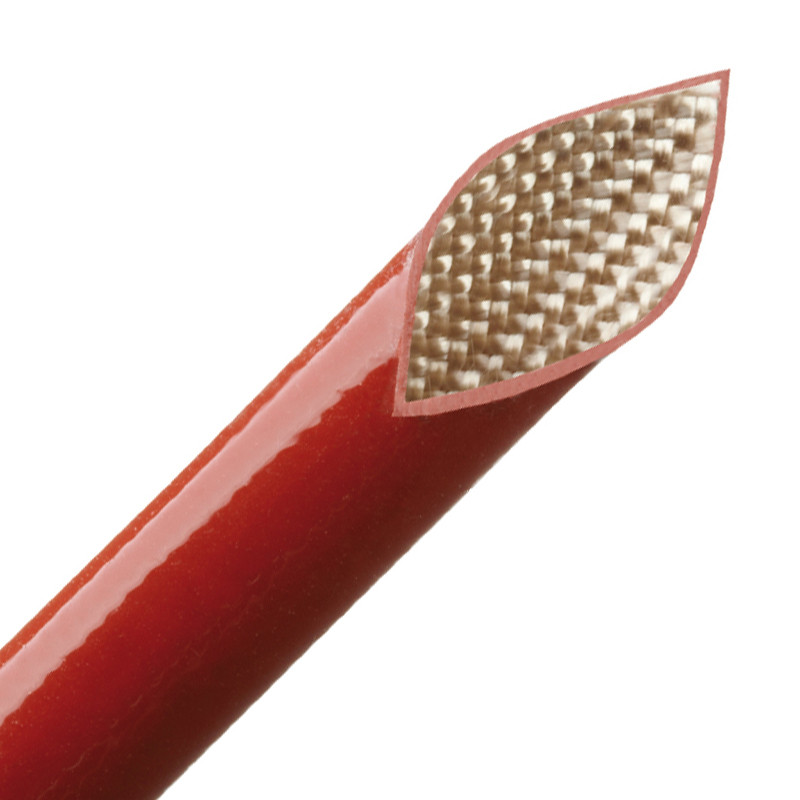

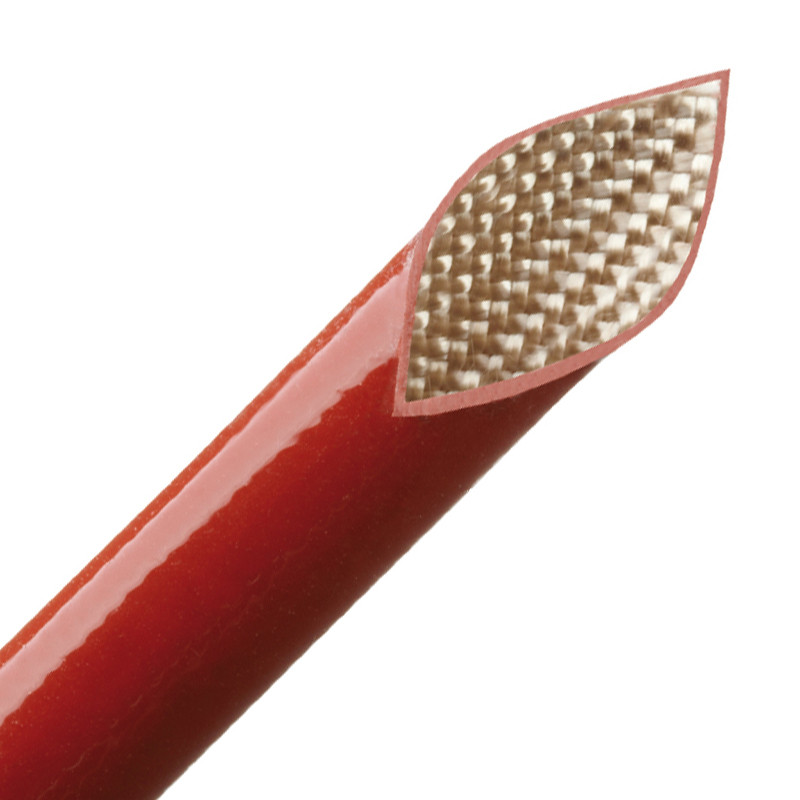

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

Characteristics

• Continuous operating temperature: -60 °C to +250 °C.

• Good resistance to humidity, ozone and UV

• Good resistance to common chemical environments.

• Compatible with most impregnation varnishes class H.

• Self-extinguishing - meets the requirements of test VW-1 as per standard UL 1441.

• Very good flexibility.

• Halogen-free.

• Dielectric strength (dry): > 4 kV.

Standard products

• Colours: brick red or black.

Packaging

• Diameters from 0.5 to 4.5 mm: 200 m spools.

• Diameters from 5 to 16 mm: 100 m spools.

• Diameters from 18 to 22 mm: 50 m spools.

• Diameters from 25 to 40 mm: 25 m spools.

Options

• More flexible sleeving (thin walls): SILIGAINE® 15C4L.

• Other diameters: contact us.

• Other colours: contact us.

• Other colours: contact us.

| INTERNAL DIAMETER | SILIGAINE 15C3 | |||

|---|---|---|---|---|

| Nominal value (mm) | Tolerance (mm) | Approximate wall thickness (mm) | Approximate linear weight (kg/km) | |

| 0.5 | ±0.15 | 0.40 | 3.3 | |

| 0.8 | ±0.15 | 0.40 | 3.9 | |

| 1 | ±0.20 | 0.40 | 4.2 | |

| 1.5 | ±0.20 | 0.40 | 5.2 | |

| 2 | ± 0.20 | 0.40 | 6.3 | |

| 2.5 | ± 0.20 | 0.40 | 7.4 | |

| 3 | ± 0.20 | 0.40 | 8.6 | |

| 3.5 | ± 0.25 | 0.40 | 9.9 | |

| 4 | ± 0.25 | 0.60 | 11.3 | |

| 4.5 | ± 0.25 | 0.60 | 12.8 | |

| 5 | ± 0.25 | 0.60 | 14.3 | |

| 6 | ± 0.25 | 0.60 | 17.6 | |

| 7 | ± 0.25 | 0.60 | 21.2 | |

| 8 | ± 0.25 | 0.60 | 25.2 | |

| 9 | ± 0.50 | 0.80 | 29.4 | |

| 10 | ± 0.50 | 0.80 | 34.0 | |

| 12 | ± 0.50 | 0.80 | 56.9 | |

| 14 | ± 1.0 | 0.80 | 74.0 | |

| 16 | ± 1.0 | 0.90 | 100 | |

| 18 | ± 1.0 | 1.00 | 123 | |

| 20 | ± 1.0 | 1.00 | 147 | |

| 22 | ± 1.0 | 1.00 | 171 | |

| 25 | ± 1.0 | 1.20 | 207 | |

| 30 | ± 2.0 | 1.30 | 272 | |

| 35 | ± 2.0 | 1.50 | 358 | |

| 40 | ± 2.0 | 1.50 | 455 | |

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Characteristics

• Continuous operating temperature: -60 °C to +250 °C.

• Good resistance to humidity, ozone and UV

• Good resistance to common chemical environments.

• Compatible with most impregnation varnishes class H.

• Self-extinguishing - meets the requirements of test VW-1 as per standard UL 1441.

• Very good flexibility.

• Halogen-free.

• Dielectric strength (dry): > 4 kV.

Standard products

• Colours: brick red or black.

Packaging

• Diameters from 0.5 to 4.5 mm: 200 m spools.

• Diameters from 5 to 16 mm: 100 m spools.

• Diameters from 18 to 22 mm: 50 m spools.

• Diameters from 25 to 40 mm: 25 m spools.

Options

• More flexible sleeving (thin walls): SILIGAINE® 15C4L.

• Other diameters: contact us.

• Other colours: contact us.

• Other colours: contact us.

| INTERNAL DIAMETER | SILIGAINE 15C3 | |||

|---|---|---|---|---|

| Nominal value (mm) | Tolerance (mm) | Approximate wall thickness (mm) | Approximate linear weight (kg/km) | |

| 0.5 | ±0.15 | 0.40 | 3.3 | |

| 0.8 | ±0.15 | 0.40 | 3.9 | |

| 1 | ±0.20 | 0.40 | 4.2 | |

| 1.5 | ±0.20 | 0.40 | 5.2 | |

| 2 | ± 0.20 | 0.40 | 6.3 | |

| 2.5 | ± 0.20 | 0.40 | 7.4 | |

| 3 | ± 0.20 | 0.40 | 8.6 | |

| 3.5 | ± 0.25 | 0.40 | 9.9 | |

| 4 | ± 0.25 | 0.60 | 11.3 | |

| 4.5 | ± 0.25 | 0.60 | 12.8 | |

| 5 | ± 0.25 | 0.60 | 14.3 | |

| 6 | ± 0.25 | 0.60 | 17.6 | |

| 7 | ± 0.25 | 0.60 | 21.2 | |

| 8 | ± 0.25 | 0.60 | 25.2 | |

| 9 | ± 0.50 | 0.80 | 29.4 | |

| 10 | ± 0.50 | 0.80 | 34.0 | |

| 12 | ± 0.50 | 0.80 | 56.9 | |

| 14 | ± 1.0 | 0.80 | 74.0 | |

| 16 | ± 1.0 | 0.90 | 100 | |

| 18 | ± 1.0 | 1.00 | 123 | |

| 20 | ± 1.0 | 1.00 | 147 | |

| 22 | ± 1.0 | 1.00 | 171 | |

| 25 | ± 1.0 | 1.20 | 207 | |

| 30 | ± 2.0 | 1.30 | 272 | |

| 35 | ± 2.0 | 1.50 | 358 | |

| 40 | ± 2.0 | 1.50 | 455 | |

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé