Musisz być zalogowany/a

Kategória

A fényképek csak tájékoztató jellegűek. Lásd a termék specifikációit

Kérjük, használjon latin karaktereket

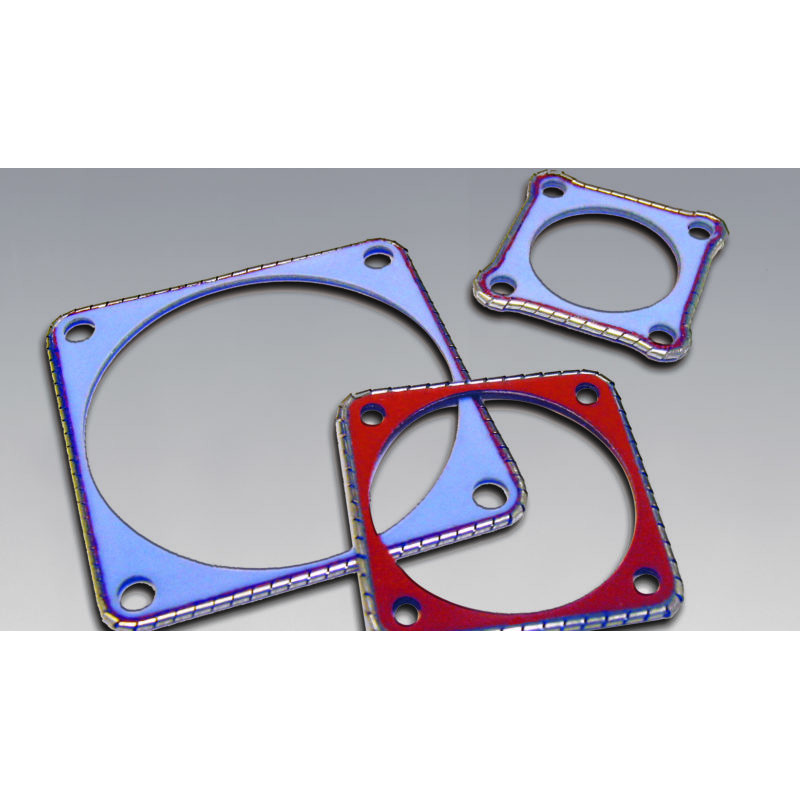

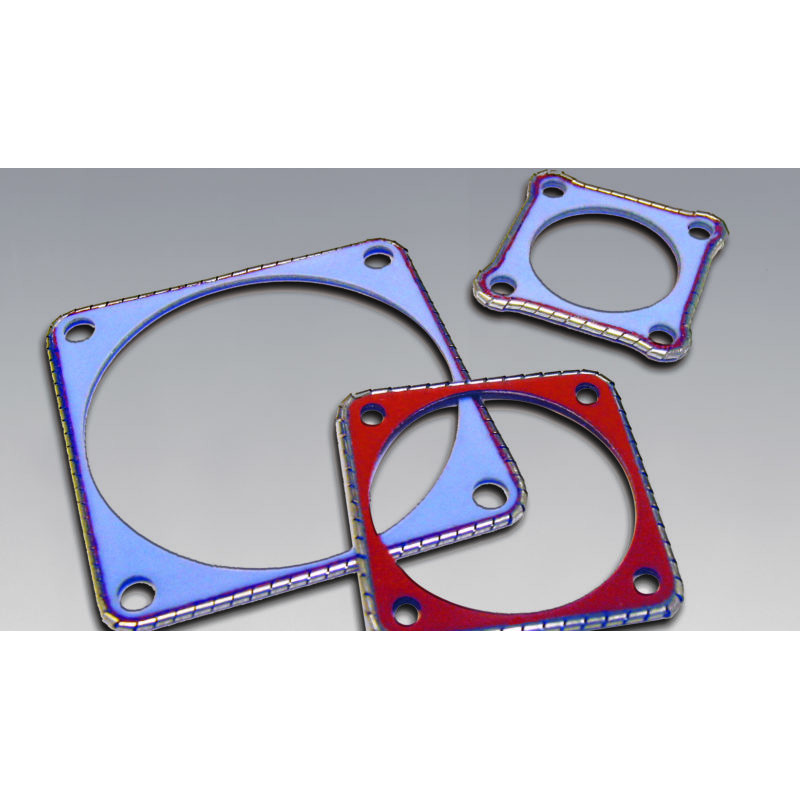

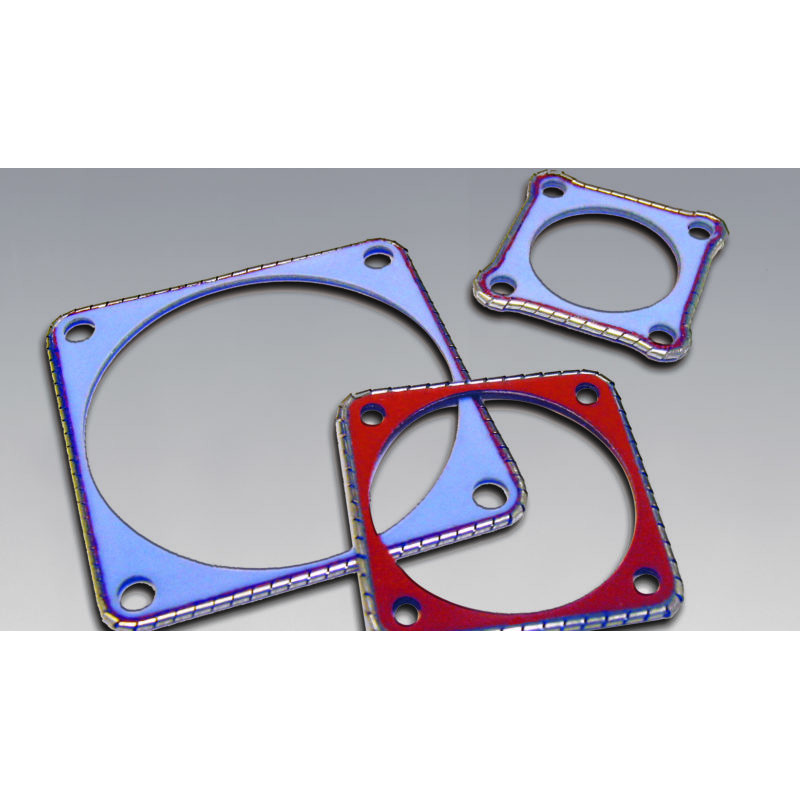

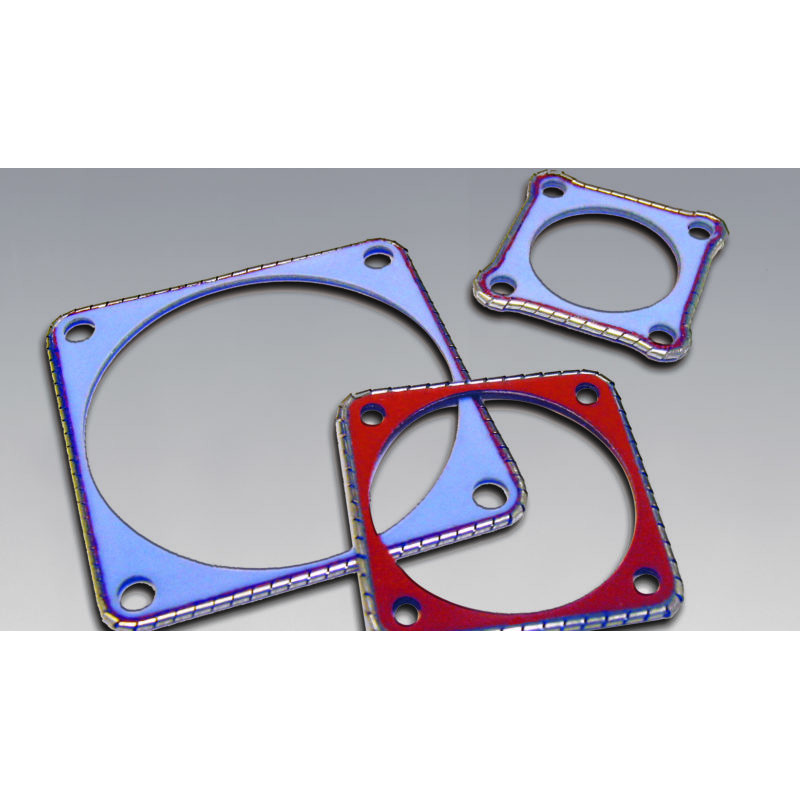

Spira’s Front-Mount EMI & Environmental Connector-Seal gaskets are designed to provide an EMI & Environmental seal in flange-mounted connectors for the life of a system. They provide superior shielding quality and an excellent and durable environmental seal.

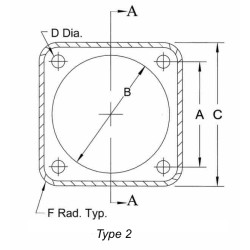

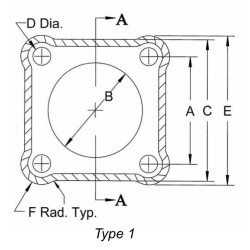

| Dash No. | MIL-C-38999 | A | B | C | D | E | F | ||||

| Series I | Series II | Series III | |||||||||

| 03S1 | 9 | 0.719 | 0.666 | 0.958 | 0.120 | 1.009* | 0.140 | ||||

| 06S1 | 11 | 0.812 | 0.806 | 1.051 | 0.120 | 1.102* | 0.140 | ||||

| 08S1 | 13 | 0.906 | 0.932 | 1.145 | 0.120 | 1.196* | 0.140 | ||||

| 10S1 | 15 | 0.969 | 1.057 | 1.243 | 0.120 | 0.137 | |||||

| 12S1 | 17 | 1.062 | 1.170 | 1.336 | 0.120 | 0.137 | |||||

| 14S1 | 19 | 1.156 | 1.307 | 1.460 | 0.120 | 0.152 | |||||

| 16S1 | 21 | 1.250 | 1.432 | 1.585 | 0.120 | 0.168 | |||||

| 18S1 | 23 | 1.375 | 1.557 | 1.710 | 0.152 | 0.168 | |||||

| 20S1 | 25 | 1.500 | 1.682 | 1.835 | 0.152 | 0.168 | |||||

| 01S2 | 8 | 0.594 | 0.563 | 0.828 | 0.120 | 0.884* | 0.140 | ||||

| 05S2 | 10 | 0.719 | 0.680 | 0.954 | 0.120 | 1.009* | 0.140 | ||||

| 07S2 | 12 | 0.812 | 0.859 | 1.047 | 0.120 | 1.102* | 0.140 | ||||

| 09S2 | 14 | 0.906 | 0.984 | 1.141 | 0.120 | 1.196* | 0.140 | ||||

| 11S2 | 16 | 0.969 | 1.068 | 1.243 | 0.120 | 0.137 | |||||

| 13S2 | 18 | 1.062 | 1.193 | 1.346 | 0.120 | 0.142 | |||||

| 15S2 | 20 | 1.156 | 1.318 | 1.471 | 0.120 | 0.158 | |||||

| 17S2 | 22 | 1.250 | 1.443 | 1.596 | 0.120 | 0.173 | |||||

| 19S2 | 24 | 1.375 | 1.570 | 1.723 | 0.152 | 0.174 | |||||

| 04S3 | 9 | 0.719 | 0.635 | 0.948 | 0.120 | 1.010* | 0.141 | ||||

| 06S3 | 11 | 0.812 | 0.760 | 1.042 | 0.120 | 1.104* | 0.141 | ||||

| 08S3 | 13 | 0.906 | 0.885 | 1.136 | 0.120 | 1.198* | 0.141 | ||||

| 10S3 | 15 | 0.969 | 1.010 | 1.254 | 0.120 | 0.143 | |||||

| 12S3 | 17 | 1.062 | 1.185 | 1.348 | 0.120 | 0.143 | |||||

| 14S3 | 19 | 1.156 | 1.260 | 1.449 | 0.120 | 0.147 | |||||

| 16S3 | 21 | 1.250 | 1.385 | 1.575 | 0.120 | 0.163 | |||||

| 18S3 | 23 | 1.375 | 1.510 | 1.701 | 0.150 | 0.163 | |||||

| 20S3 | 25 | 1.500 | 1.635 | 1.823 | 0.150 | 0.162 | |||||

| MS-3412, MIL- DTL 5015 Series II | MIL-C-28840 | A | B | C | D | F | |||||

| 22 | 8 | 0.594 | 0.510 | 0.875 | 0.120 | 0.141 | |||||

| 23 | 10 | 0.719 | 0.635 | 1.000 | 0.120 | 0.141 | |||||

| 24 | 11 | 0.750 | 0.760 | 1.023 | 0.120 | 0.137 | |||||

| 25 | 12 | 0.812 | 0.760 | 1.094 | 0.120 | 0.141 | |||||

| 26 | 13 | 0.843 | 0.885 | 1.138 | 0.120 | 0.148 | |||||

| 27 | 14 | 0.906 | 0.885 | 1.188 | 0.120 | 0.141 | |||||

| 28 | 15 | 0.968 | 1.072 | 1.258 | 0.120 | 0.145 | |||||

| 29 | 16 | 0.969 | 1.010 | 1.281 | 0.120 | 0.156 | |||||

| 30 | 17 | 1.015 | 1.135 | 1.383 | 0.120 | 0.184 | |||||

| 31 | 18 | 1.062 | 1.135 | 1.375 | 0.120 | 0.157 | |||||

| 32 | 19 | 1.140 | 1.322 | 1.508 | 0.120 | 0.184 | |||||

| 33 | 20 | 1.156 | 1.260 | 1.500 | 0.120 | 0.172 | |||||

| 34 | 22 | 1.250 | 1.385 | 1.625 | 0.120 | 0.188 | |||||

| 35 | 23 | 1.281 | 1.510 | 1.718 | 0.120 | 0.219 | |||||

| 36 | 24 | 1.375 | 1.510 | 1.750 | 0.150 | 0.188 | |||||

| 37 | 25 | 1.392 | 1.635 | 1.818 | 0.150 | 0.213 | |||||

| 38 | 28 | 1.562 | 1.760 | 2.000 | 0.150 | 0.219 | |||||

| 39 | 29 | 1.568 | 1.885 | 2.138 | 0.150 | 0.285 | |||||

| 40 | 32 | 1.750 | 2.010 | 2.250 | 0.170 | 0.250 | |||||

| 41 | 33 | 1.734 | 2.073 | 2.328 | 0.170 | 0.297 | |||||

| 42 | 36 | 1.938 | 2.260 | 2.500 | 0.170 | 0.281 | |||||

| 43 | 40 | 2.188 | 2.510 | 2.750 | 0.170 | 0.281 | |||||

| 44 | 44 | 2.375 | 2.760 | 3.000 | 0.170 | 0.313 | |||||

| 45 | 48 | 2.625 | 3.010 | 3.250 | 0.170 | 0.313 | |||||

* Type 1 gaskets have an E dimension to provide sufficient environmental sealing on smaller sizes.

Note that the dash numbers and sizes are different for each type of Connector-Seal gasket: the Environmental Connector-Seal Standard-Mount (ECS), the Front-Mount Environmental Connector-Seal (FMECS) and the EMI-Only version (CS).

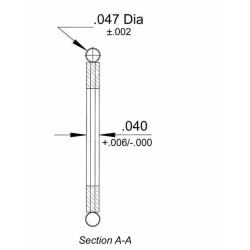

The Front-Mount EMI & Environmental Connector-Seal gaskets have a Spira-Shield O-Ring gasket on the outside of the frame to provide an environmental seal when front mounting the connector. The frame consists of a metal plate sealed on both sides with vulcanized silicone or fluorosilicone rubber elastomer. The metal plate eliminates cold flow of the environmental sealing elastomer and provides a very durable and reusable gasket. Please see the related products for a more cost-effective back-mounted EMI & Environmental Connector-Seal.

Frame: Corrosion resistant Stainless Steel, between silicone or fluorosilicone rubber elastomer.

Spiral: Spira-Shield Standard force tin/lead plated beryllium copper gasket is standard. Other spiral plating options are available.

Connector-Seal gaskets offer shielding quality from 116 to 152 dB. The level is dependent on contact surfaces and may vary depending on your specific application. Refer to our Shielding Quality charts for more complete performance data.

The standard spiral (“T”) is electroplated, 90% tin, 10% lead (edges unplated). Plating options can be specified by changing the prefix in the part number:

E: Edge tin/lead plating (includes edges) for high humidity or salt-fog environments

IW: RoHS compliant tin plating (Example: ECS-IW-21 /S)

EIW: RoHS compliant edge tin plating for high humidity or salt-fog

NI: Stainless steel

TNI: Tin-plated stainless steel

IWNI: RoHS tin-plated stainless steel

The default frame is stainless steel sealed on both sides by silicone or fluorosilicone rubber elastomer.

Elastomers are available in either silicone or fluorosilicone rubber.

Érdekel ez a termék? További információra vagy egyedi árajánlatra van szüksége?

Musisz być zalogowany/a

Spira’s Front-Mount EMI & Environmental Connector-Seal gaskets are designed to provide an EMI & Environmental seal in flange-mounted connectors for the life of a system. They provide superior shielding quality and an excellent and durable environmental seal.

| Dash No. | MIL-C-38999 | A | B | C | D | E | F | ||||

| Series I | Series II | Series III | |||||||||

| 03S1 | 9 | 0.719 | 0.666 | 0.958 | 0.120 | 1.009* | 0.140 | ||||

| 06S1 | 11 | 0.812 | 0.806 | 1.051 | 0.120 | 1.102* | 0.140 | ||||

| 08S1 | 13 | 0.906 | 0.932 | 1.145 | 0.120 | 1.196* | 0.140 | ||||

| 10S1 | 15 | 0.969 | 1.057 | 1.243 | 0.120 | 0.137 | |||||

| 12S1 | 17 | 1.062 | 1.170 | 1.336 | 0.120 | 0.137 | |||||

| 14S1 | 19 | 1.156 | 1.307 | 1.460 | 0.120 | 0.152 | |||||

| 16S1 | 21 | 1.250 | 1.432 | 1.585 | 0.120 | 0.168 | |||||

| 18S1 | 23 | 1.375 | 1.557 | 1.710 | 0.152 | 0.168 | |||||

| 20S1 | 25 | 1.500 | 1.682 | 1.835 | 0.152 | 0.168 | |||||

| 01S2 | 8 | 0.594 | 0.563 | 0.828 | 0.120 | 0.884* | 0.140 | ||||

| 05S2 | 10 | 0.719 | 0.680 | 0.954 | 0.120 | 1.009* | 0.140 | ||||

| 07S2 | 12 | 0.812 | 0.859 | 1.047 | 0.120 | 1.102* | 0.140 | ||||

| 09S2 | 14 | 0.906 | 0.984 | 1.141 | 0.120 | 1.196* | 0.140 | ||||

| 11S2 | 16 | 0.969 | 1.068 | 1.243 | 0.120 | 0.137 | |||||

| 13S2 | 18 | 1.062 | 1.193 | 1.346 | 0.120 | 0.142 | |||||

| 15S2 | 20 | 1.156 | 1.318 | 1.471 | 0.120 | 0.158 | |||||

| 17S2 | 22 | 1.250 | 1.443 | 1.596 | 0.120 | 0.173 | |||||

| 19S2 | 24 | 1.375 | 1.570 | 1.723 | 0.152 | 0.174 | |||||

| 04S3 | 9 | 0.719 | 0.635 | 0.948 | 0.120 | 1.010* | 0.141 | ||||

| 06S3 | 11 | 0.812 | 0.760 | 1.042 | 0.120 | 1.104* | 0.141 | ||||

| 08S3 | 13 | 0.906 | 0.885 | 1.136 | 0.120 | 1.198* | 0.141 | ||||

| 10S3 | 15 | 0.969 | 1.010 | 1.254 | 0.120 | 0.143 | |||||

| 12S3 | 17 | 1.062 | 1.185 | 1.348 | 0.120 | 0.143 | |||||

| 14S3 | 19 | 1.156 | 1.260 | 1.449 | 0.120 | 0.147 | |||||

| 16S3 | 21 | 1.250 | 1.385 | 1.575 | 0.120 | 0.163 | |||||

| 18S3 | 23 | 1.375 | 1.510 | 1.701 | 0.150 | 0.163 | |||||

| 20S3 | 25 | 1.500 | 1.635 | 1.823 | 0.150 | 0.162 | |||||

| MS-3412, MIL- DTL 5015 Series II | MIL-C-28840 | A | B | C | D | F | |||||

| 22 | 8 | 0.594 | 0.510 | 0.875 | 0.120 | 0.141 | |||||

| 23 | 10 | 0.719 | 0.635 | 1.000 | 0.120 | 0.141 | |||||

| 24 | 11 | 0.750 | 0.760 | 1.023 | 0.120 | 0.137 | |||||

| 25 | 12 | 0.812 | 0.760 | 1.094 | 0.120 | 0.141 | |||||

| 26 | 13 | 0.843 | 0.885 | 1.138 | 0.120 | 0.148 | |||||

| 27 | 14 | 0.906 | 0.885 | 1.188 | 0.120 | 0.141 | |||||

| 28 | 15 | 0.968 | 1.072 | 1.258 | 0.120 | 0.145 | |||||

| 29 | 16 | 0.969 | 1.010 | 1.281 | 0.120 | 0.156 | |||||

| 30 | 17 | 1.015 | 1.135 | 1.383 | 0.120 | 0.184 | |||||

| 31 | 18 | 1.062 | 1.135 | 1.375 | 0.120 | 0.157 | |||||

| 32 | 19 | 1.140 | 1.322 | 1.508 | 0.120 | 0.184 | |||||

| 33 | 20 | 1.156 | 1.260 | 1.500 | 0.120 | 0.172 | |||||

| 34 | 22 | 1.250 | 1.385 | 1.625 | 0.120 | 0.188 | |||||

| 35 | 23 | 1.281 | 1.510 | 1.718 | 0.120 | 0.219 | |||||

| 36 | 24 | 1.375 | 1.510 | 1.750 | 0.150 | 0.188 | |||||

| 37 | 25 | 1.392 | 1.635 | 1.818 | 0.150 | 0.213 | |||||

| 38 | 28 | 1.562 | 1.760 | 2.000 | 0.150 | 0.219 | |||||

| 39 | 29 | 1.568 | 1.885 | 2.138 | 0.150 | 0.285 | |||||

| 40 | 32 | 1.750 | 2.010 | 2.250 | 0.170 | 0.250 | |||||

| 41 | 33 | 1.734 | 2.073 | 2.328 | 0.170 | 0.297 | |||||

| 42 | 36 | 1.938 | 2.260 | 2.500 | 0.170 | 0.281 | |||||

| 43 | 40 | 2.188 | 2.510 | 2.750 | 0.170 | 0.281 | |||||

| 44 | 44 | 2.375 | 2.760 | 3.000 | 0.170 | 0.313 | |||||

| 45 | 48 | 2.625 | 3.010 | 3.250 | 0.170 | 0.313 | |||||

* Type 1 gaskets have an E dimension to provide sufficient environmental sealing on smaller sizes.

Note that the dash numbers and sizes are different for each type of Connector-Seal gasket: the Environmental Connector-Seal Standard-Mount (ECS), the Front-Mount Environmental Connector-Seal (FMECS) and the EMI-Only version (CS).

The Front-Mount EMI & Environmental Connector-Seal gaskets have a Spira-Shield O-Ring gasket on the outside of the frame to provide an environmental seal when front mounting the connector. The frame consists of a metal plate sealed on both sides with vulcanized silicone or fluorosilicone rubber elastomer. The metal plate eliminates cold flow of the environmental sealing elastomer and provides a very durable and reusable gasket. Please see the related products for a more cost-effective back-mounted EMI & Environmental Connector-Seal.

Frame: Corrosion resistant Stainless Steel, between silicone or fluorosilicone rubber elastomer.

Spiral: Spira-Shield Standard force tin/lead plated beryllium copper gasket is standard. Other spiral plating options are available.

Connector-Seal gaskets offer shielding quality from 116 to 152 dB. The level is dependent on contact surfaces and may vary depending on your specific application. Refer to our Shielding Quality charts for more complete performance data.

The standard spiral (“T”) is electroplated, 90% tin, 10% lead (edges unplated). Plating options can be specified by changing the prefix in the part number:

E: Edge tin/lead plating (includes edges) for high humidity or salt-fog environments

IW: RoHS compliant tin plating (Example: ECS-IW-21 /S)

EIW: RoHS compliant edge tin plating for high humidity or salt-fog

NI: Stainless steel

TNI: Tin-plated stainless steel

IWNI: RoHS tin-plated stainless steel

The default frame is stainless steel sealed on both sides by silicone or fluorosilicone rubber elastomer.

Elastomers are available in either silicone or fluorosilicone rubber.

A megfogalmazott véleményedet nem lehet elküldeni

Hozzászólás jelentése

Jelentés elküldve

Jelentésed beküldése nem lehetséges

Írd meg véleményedet

Vélemény elküldve

Véleményed nem lehet elküldeni