Jūs turite būti prisijungę

Category

Nuotraukos yra skirtos tik informaciniams tikslams. Peržiūrėkite produkto specifikaciją

please use latin characters

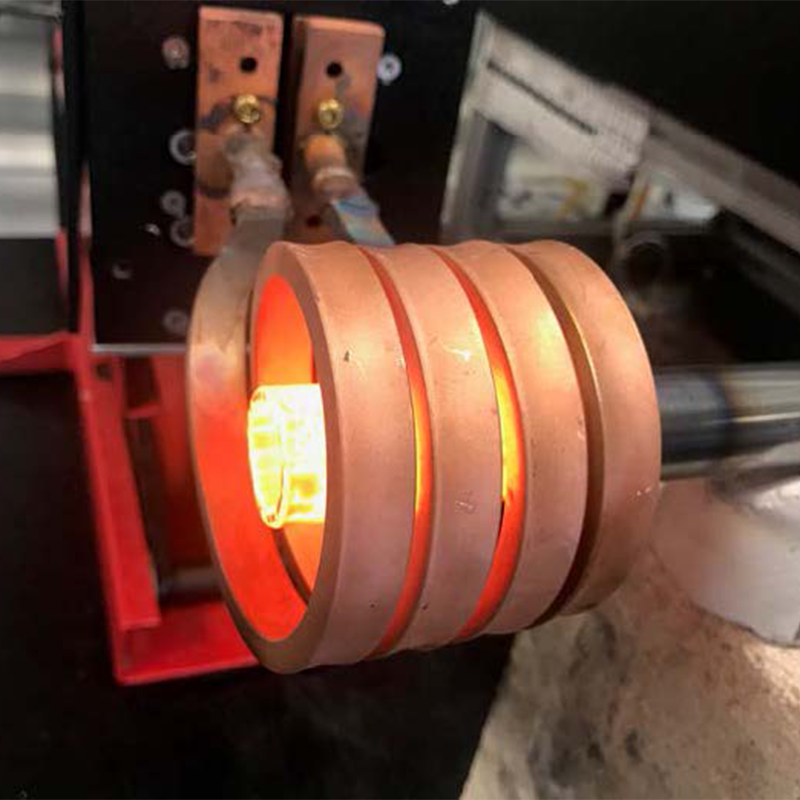

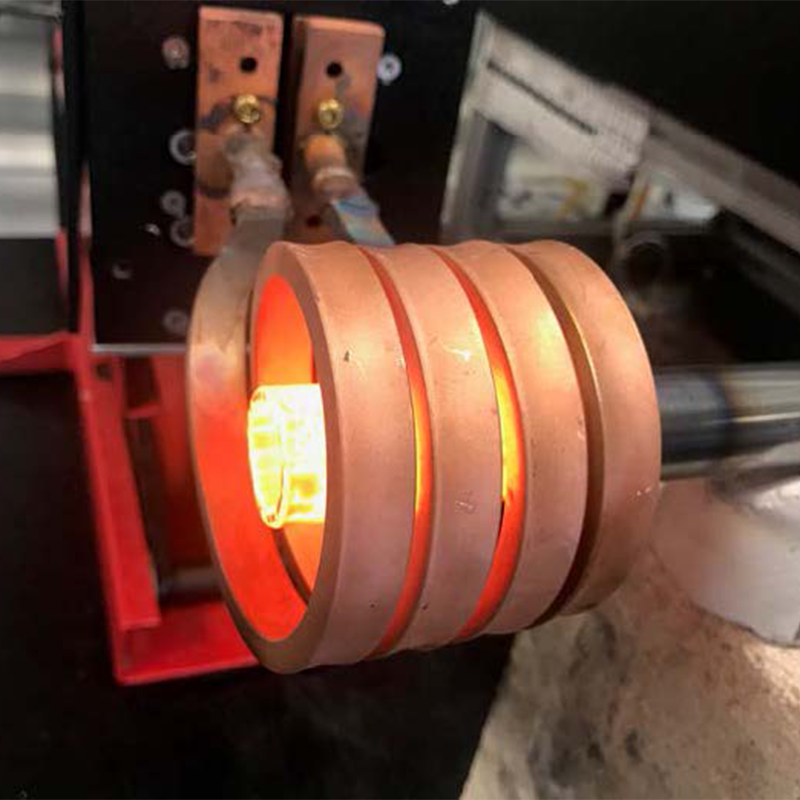

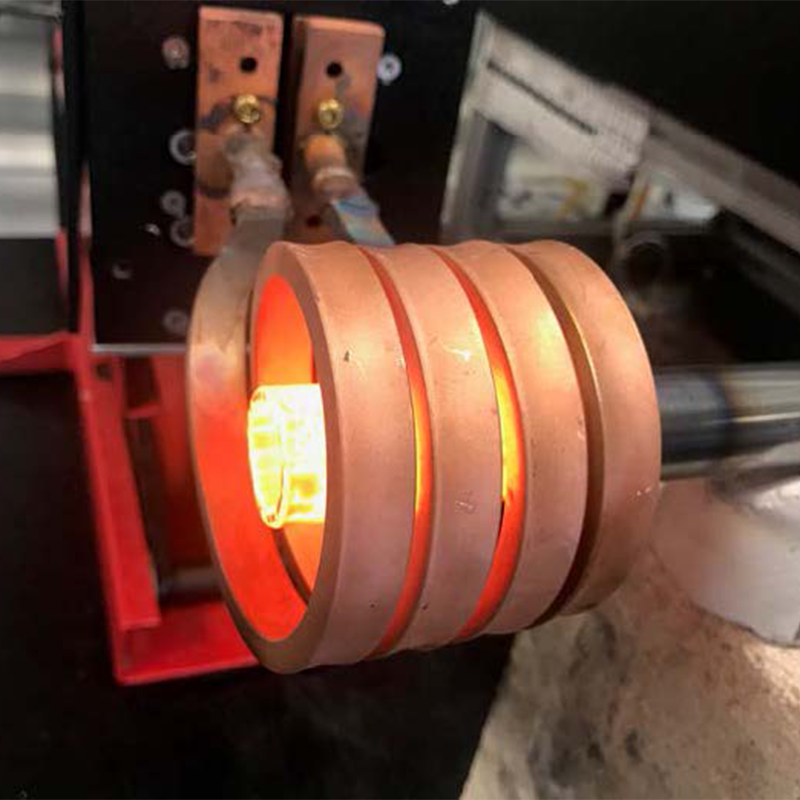

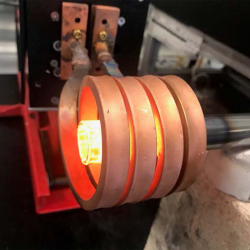

Objective: To heat steel tube ends for a flattening/bending applications; the end customer uses products in the manufacturing industry.

Frequency: 191 kHz

Material: Steel tubes

Temperature: 1600 ºF (871 ºC)

Process: First, temperature indicating paint was applied to the part, which dissolves when the part reaches the target temperature. It took less than 20 seconds to heat the provided smaller tube sample to 1600 °F (871 °C) and it took 40 seconds to heat the larger sample tube to temperature. The client was seeing heating times of at least two minutes with an oven, so this is a significant improvement.

Benefits:

Ar Jūs domina šis produktas? Ar Jums reikia papildomos informacijos ar individualaus pasiūlymo?

tu turi būti prisijungęs

Objective: To heat steel tube ends for a flattening/bending applications; the end customer uses products in the manufacturing industry.

Frequency: 191 kHz

Material: Steel tubes

Temperature: 1600 ºF (871 ºC)

Process: First, temperature indicating paint was applied to the part, which dissolves when the part reaches the target temperature. It took less than 20 seconds to heat the provided smaller tube sample to 1600 °F (871 °C) and it took 40 seconds to heat the larger sample tube to temperature. The client was seeing heating times of at least two minutes with an oven, so this is a significant improvement.

Benefits:

Jūsų atsiliepimo įvertinimas negali būti išsiųstas

Pranešti apie komentarą

Pranešimas apie atsiliepimą išsiųstas

Jūsų pranešimas apie atsiliepimą neišsiųstas

Parašyti savo atsiliepimą

Atsiliepimas išsiųstas

Jūsų atsiliepimas neišsiųstas