Jūs turite būti prisijungę

Category

Nuotraukos yra skirtos tik informaciniams tikslams. Peržiūrėkite produkto specifikaciją

please use latin characters

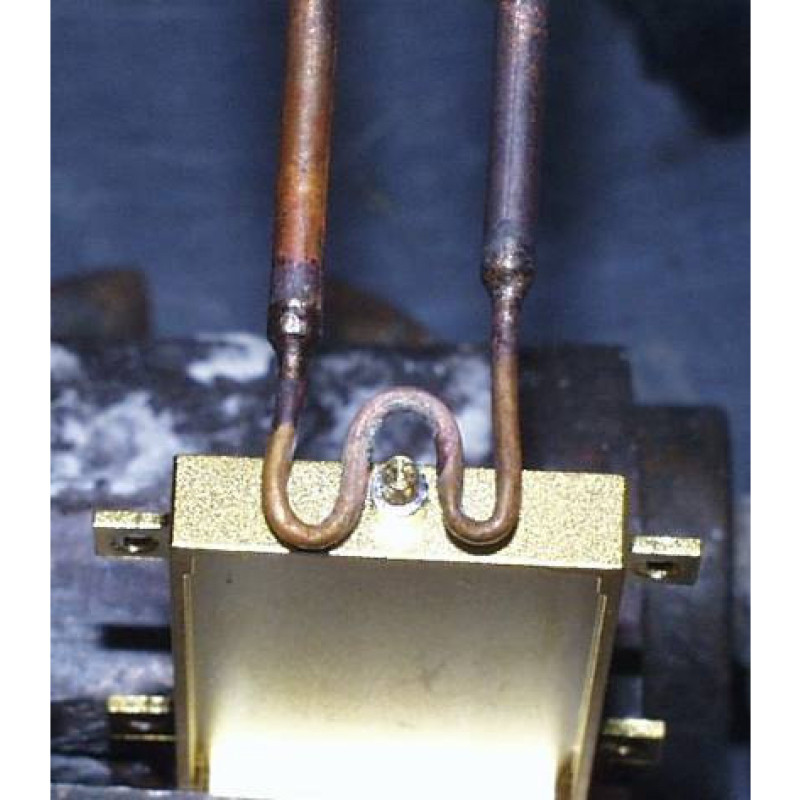

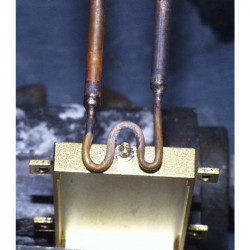

Objective: Soldering a fiber optics cable in a ferrule to form a hermetic seal.

Frequency: 346 kHz

Material: Panda PM fiber 0.0098” (.25mm) dia, kovar ferrule 0.086” (2.2mm) dia and metal enclosure 1.96” x 1.06” x 0.23” thick (50mm x 27mm x 5.9mm thick), solder preforms and flux

Temperature: 450 ºF (232 ºC)

A single turn channel “C” coil is used for this soldering application. Assembly is fluxed at the joint area and power is applied for 15 seconds to create the hermetic seal in the ferrule. The customer chose our solution due to the ability to design the single channel “C” coil. The coil heats quickly so that the heat does not travel to heat sensitive components in the case.

Ar Jūs domina šis produktas? Ar Jums reikia papildomos informacijos ar individualaus pasiūlymo?

tu turi būti prisijungęs

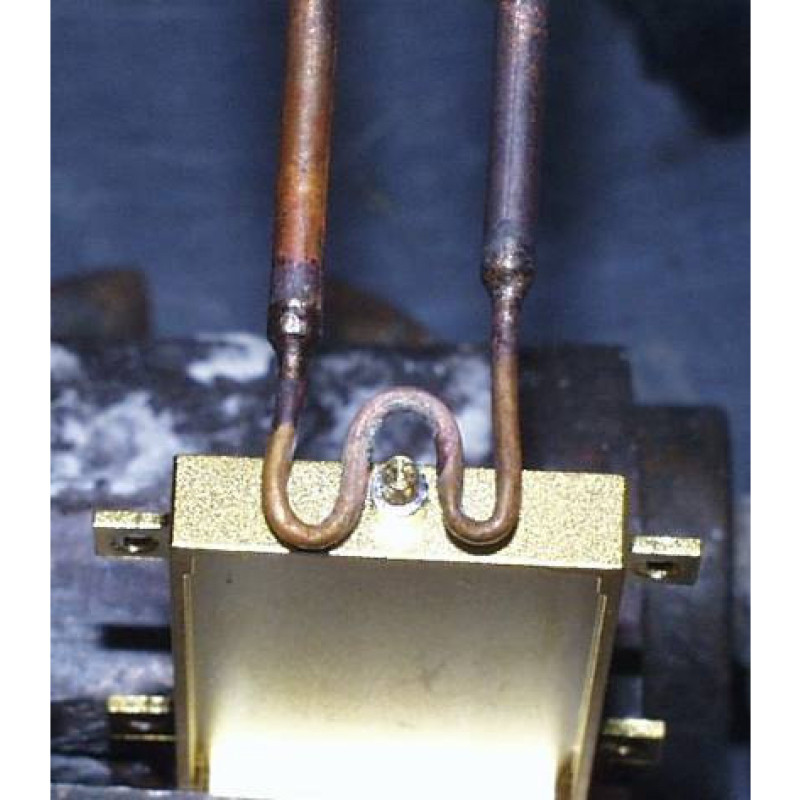

Objective: Soldering a fiber optics cable in a ferrule to form a hermetic seal.

Frequency: 346 kHz

Material: Panda PM fiber 0.0098” (.25mm) dia, kovar ferrule 0.086” (2.2mm) dia and metal enclosure 1.96” x 1.06” x 0.23” thick (50mm x 27mm x 5.9mm thick), solder preforms and flux

Temperature: 450 ºF (232 ºC)

A single turn channel “C” coil is used for this soldering application. Assembly is fluxed at the joint area and power is applied for 15 seconds to create the hermetic seal in the ferrule. The customer chose our solution due to the ability to design the single channel “C” coil. The coil heats quickly so that the heat does not travel to heat sensitive components in the case.

Jūsų atsiliepimo įvertinimas negali būti išsiųstas

Pranešti apie komentarą

Pranešimas apie atsiliepimą išsiųstas

Jūsų pranešimas apie atsiliepimą neišsiųstas

Parašyti savo atsiliepimą

Atsiliepimas išsiųstas

Jūsų atsiliepimas neišsiųstas