Jūs turite būti prisijungę

Category

Nuotraukos yra skirtos tik informaciniams tikslams. Peržiūrėkite produkto specifikaciją

please use latin characters

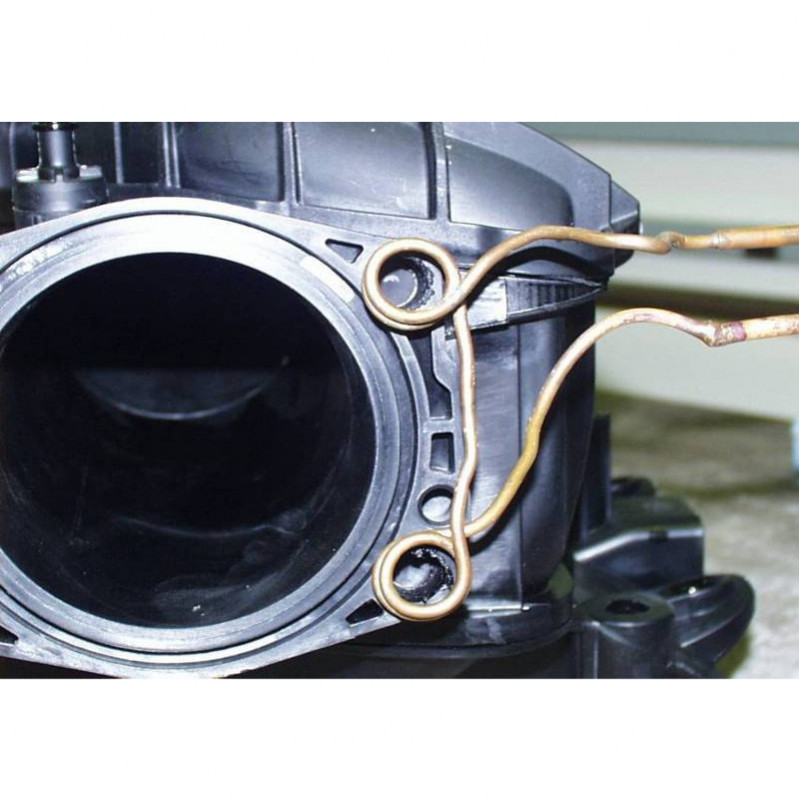

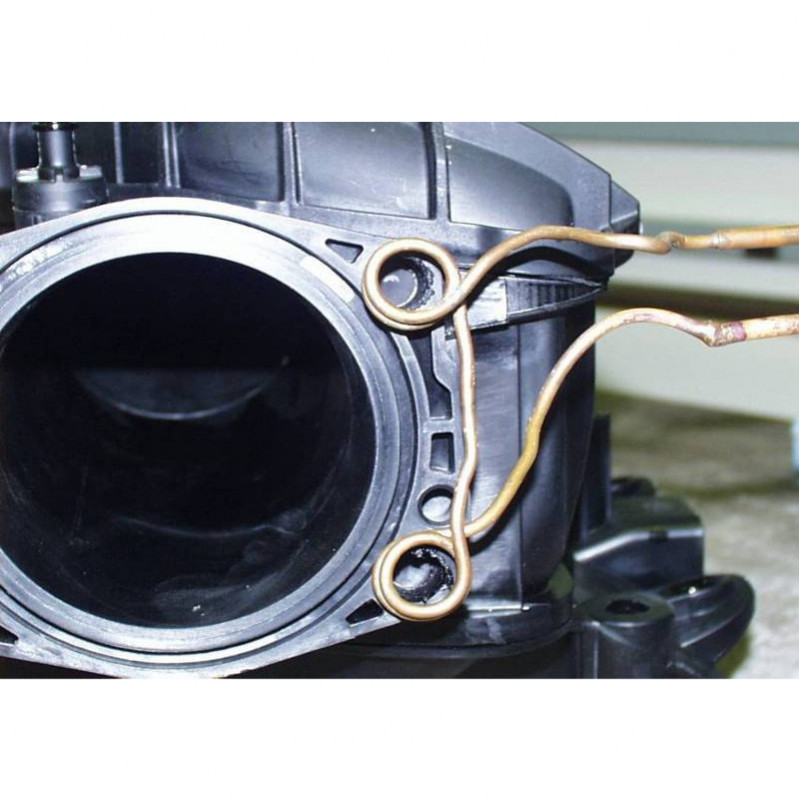

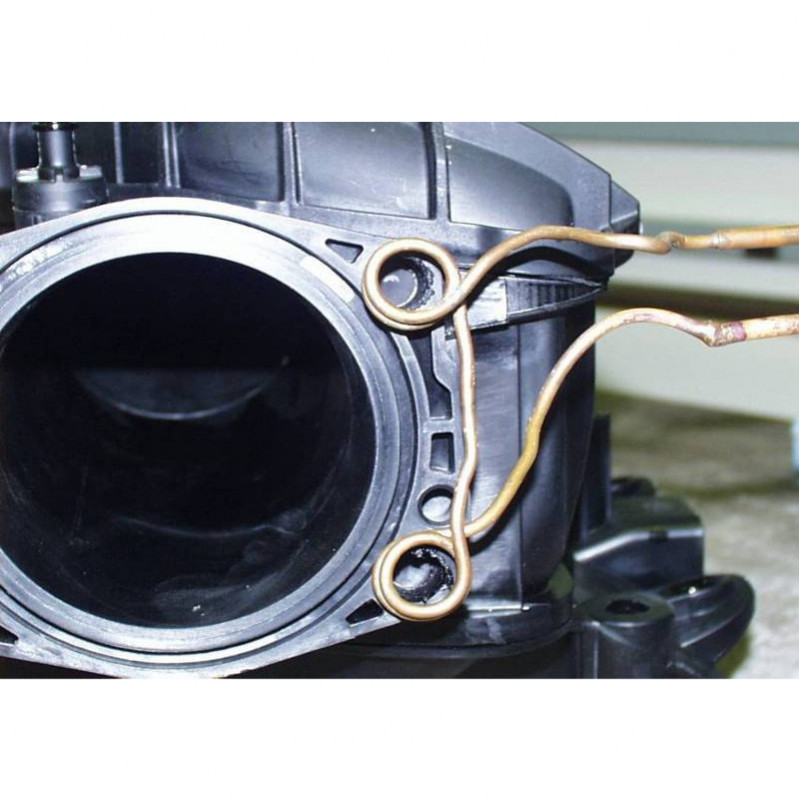

Objective: Heat a 0.50” (12.7)mm brass insert for debonding application.

Frequency: 215 kHz

Material: Intake manifold and 0.50” (12.7)mm diameter brass insert.

Temperature: 500 °F (260 °C)

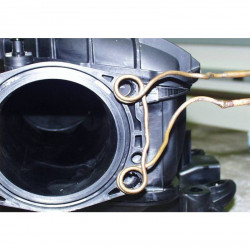

A four-turn two-position helical coil is used to debond the inserts from the plastic. The coil is placed against the manifold and power is applied to the two inserts for 15 seconds to soften the plastic. Power is turned off and a threaded steel screw is inserted into the parts and the inserts are easily removed from the manifold.

This debonding process is for recycling 10,000 defective parts that QES has received the contract for debond the brass from the plastic and recycle the plastic. Induction makes it possible to simultaneously heat both inserts for removal saving time in the recycle process.

Ar Jūs domina šis produktas? Ar Jums reikia papildomos informacijos ar individualaus pasiūlymo?

tu turi būti prisijungęs

Objective: Heat a 0.50” (12.7)mm brass insert for debonding application.

Frequency: 215 kHz

Material: Intake manifold and 0.50” (12.7)mm diameter brass insert.

Temperature: 500 °F (260 °C)

A four-turn two-position helical coil is used to debond the inserts from the plastic. The coil is placed against the manifold and power is applied to the two inserts for 15 seconds to soften the plastic. Power is turned off and a threaded steel screw is inserted into the parts and the inserts are easily removed from the manifold.

This debonding process is for recycling 10,000 defective parts that QES has received the contract for debond the brass from the plastic and recycle the plastic. Induction makes it possible to simultaneously heat both inserts for removal saving time in the recycle process.

Jūsų atsiliepimo įvertinimas negali būti išsiųstas

Pranešti apie komentarą

Pranešimas apie atsiliepimą išsiųstas

Jūsų pranešimas apie atsiliepimą neišsiųstas

Parašyti savo atsiliepimą

Atsiliepimas išsiųstas

Jūsų atsiliepimas neišsiųstas