Jūs turite būti prisijungę

Category

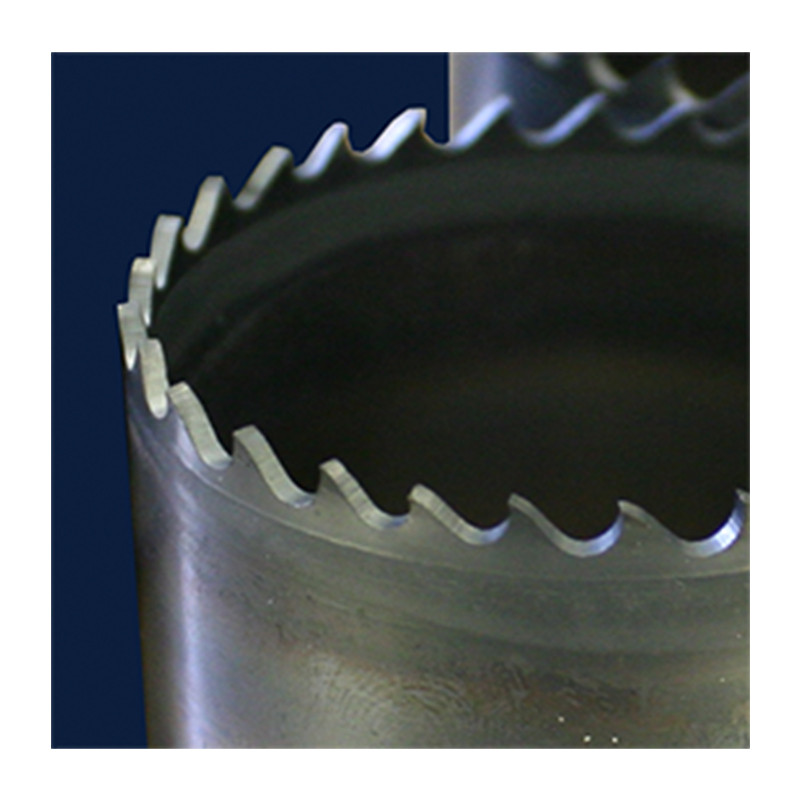

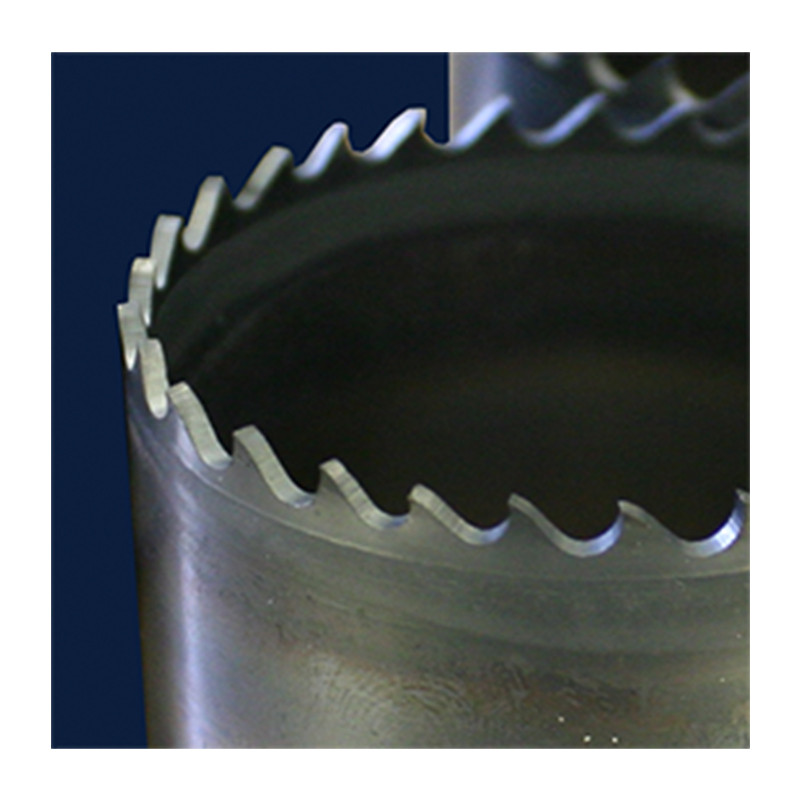

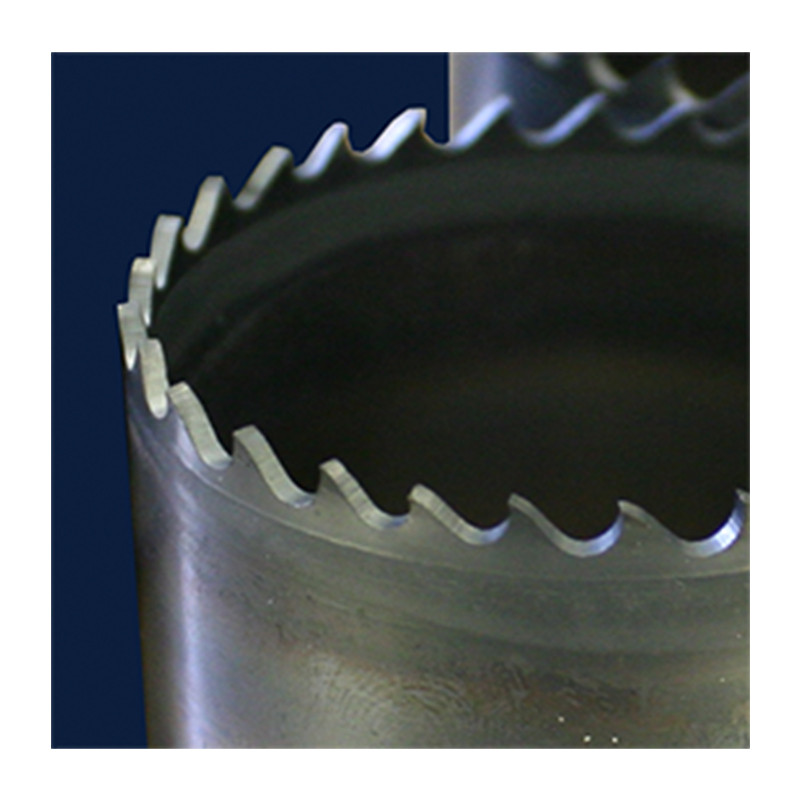

Nuotraukos yra skirtos tik informaciniams tikslams. Peržiūrėkite produkto specifikaciją

please use latin characters

Grūdinimas yra šiluminio apdorojimo metodas, kurio tikslas – pasiekti padidintą kietumą, atsparumą dilimui, atsparumą tempimui, sumažinant plastingumą ir padidinus trapumą. Pagal grūdinimo gylį išskiriamas tūrinis ir paviršinis grūdinimas. Tūrinis grūdinimas apima medžiagos kaitinimą visame jos peršvityje iki reikiamos perėjimo temperatūros, laikymą šioje temperatūroje ir aušinimą tinkamu greičiu. Šis procesas taikomas vidutinio ir aukšto anglies kiekio plienų grūdinimui, siekiant pasiekti vidutinį atsparumą ir kietumą. Paviršinis grūdinimas apima greitą viršutinio sluoksnio kaitinimą iki reikiamos perėjimo temperatūros ir greitą aušinimą. Tokiu būdu pasiekiamas padidintas kietumas ir atsparumas tik iki nustatyto gylio, o likusioje medžiagos dalyje išlieka negrūdinta struktūra. Dažniausiai aušinimo priemonės yra: alyva, oras, vanduo, vanduo su tirpiais polimerais ir kt.

Šiuolaikiniai indukciniai šildymo metodai užtikrina patikimą, bekontaktį šildymą per minimalų laiką be atviros liepsnos. Svarbi savybė yra proceso kartojamumas ir tikslumas – galimybė nustatyti laiką, temperatūrą, kontroliuoti grūdinimo gylį, aušinimą ir detalių apdorojimo plotą. Puslaidininkinės sistemos gali šildyti net labai mažus plotus, užtikrinant tikslų gamybos proceso tolerancijų laikymąsi.

Indukcinis grūdinimas atliekamas dviem būdais. Pirmas – statinis grūdinimas, kai kaitinimo operacija atliekama be elementų ir induktoriaus padėties keitimo tarpusavyje. Šis metodas išsiskiria greitumu, nereikalauja sudėtingos automatikos ir leidžia tiksliai nustatyti šildymo plotą, net ir sudėtingos formos įdėklams. Antrasis metodas – progresinis grūdinimas, kai kaitinimo operacija atliekama keičiant elementų ir induktoriaus padėtį tarpusavyje. Tai leidžia grūdinti dideles ir didelio dydžio įdėklus, taip pat šildyti kelias nustatytas detalių sritis, nereikalaujant rankinio pozicijų keitimo.

Šiluminis apdorojimas naudojant indukcines sistemas idealiai tinka pramonėje, kurioje reikalaujama automatizuoto, tiksliojo ir tuo pačiu greito proceso. Indukcinis šildymas yra itin efektyvus didesnėms įmonėms, turinčioms daugybę gamybos linijų, dirbančių nepertraukiamu režimu, nes padidina našumą. Mažesniems gamintojams papildomas privalumas – beveik momentinis mašinos paleidimas. Esant gamybos pertraukoms, mašina nebūtinai turi būti įjungta, kaip įprastose krosnyse.

Atvėsinimas yra šiluminio apdorojimo metodas, kurio tikslas – sumažinti trapumą, trapumą, kietumą iki reikiamo lygio ir pašalinti grūdinimo įtempimus pliene, anksčiau grūdintame. Šis procesas vyksta palyginti žemose temperatūrose, žemesnėse nei grūdinimo temperatūra. Detalė kaitinama, tam tikrą laiką laikoma aukštesnėje temperatūroje ir tada lėtai aušinama.

Atvėsinimas, atliekamas naudojant indukcines sistemas, suteikia daug privalumų, aprašytų grūdinimo procese, tokių kaip trumpesnis proceso laikas (net iki kelių sekundžių!), energijos taupymas, tikslus kontrolė ir pakartojamumas. Tokios sistemų integracija gamybos linijose leidžia supaprastinti proceso valdymą, paspartinti gamybą ir padidinti pelną.

Ar Jūs domina šis produktas? Ar Jums reikia papildomos informacijos ar individualaus pasiūlymo?

tu turi būti prisijungęs

Grūdinimas yra šiluminio apdorojimo metodas, kurio tikslas – pasiekti padidintą kietumą, atsparumą dilimui, atsparumą tempimui, sumažinant plastingumą ir padidinus trapumą. Pagal grūdinimo gylį išskiriamas tūrinis ir paviršinis grūdinimas. Tūrinis grūdinimas apima medžiagos kaitinimą visame jos peršvityje iki reikiamos perėjimo temperatūros, laikymą šioje temperatūroje ir aušinimą tinkamu greičiu. Šis procesas taikomas vidutinio ir aukšto anglies kiekio plienų grūdinimui, siekiant pasiekti vidutinį atsparumą ir kietumą. Paviršinis grūdinimas apima greitą viršutinio sluoksnio kaitinimą iki reikiamos perėjimo temperatūros ir greitą aušinimą. Tokiu būdu pasiekiamas padidintas kietumas ir atsparumas tik iki nustatyto gylio, o likusioje medžiagos dalyje išlieka negrūdinta struktūra. Dažniausiai aušinimo priemonės yra: alyva, oras, vanduo, vanduo su tirpiais polimerais ir kt.

Šiuolaikiniai indukciniai šildymo metodai užtikrina patikimą, bekontaktį šildymą per minimalų laiką be atviros liepsnos. Svarbi savybė yra proceso kartojamumas ir tikslumas – galimybė nustatyti laiką, temperatūrą, kontroliuoti grūdinimo gylį, aušinimą ir detalių apdorojimo plotą. Puslaidininkinės sistemos gali šildyti net labai mažus plotus, užtikrinant tikslų gamybos proceso tolerancijų laikymąsi.

Indukcinis grūdinimas atliekamas dviem būdais. Pirmas – statinis grūdinimas, kai kaitinimo operacija atliekama be elementų ir induktoriaus padėties keitimo tarpusavyje. Šis metodas išsiskiria greitumu, nereikalauja sudėtingos automatikos ir leidžia tiksliai nustatyti šildymo plotą, net ir sudėtingos formos įdėklams. Antrasis metodas – progresinis grūdinimas, kai kaitinimo operacija atliekama keičiant elementų ir induktoriaus padėtį tarpusavyje. Tai leidžia grūdinti dideles ir didelio dydžio įdėklus, taip pat šildyti kelias nustatytas detalių sritis, nereikalaujant rankinio pozicijų keitimo.

Šiluminis apdorojimas naudojant indukcines sistemas idealiai tinka pramonėje, kurioje reikalaujama automatizuoto, tiksliojo ir tuo pačiu greito proceso. Indukcinis šildymas yra itin efektyvus didesnėms įmonėms, turinčioms daugybę gamybos linijų, dirbančių nepertraukiamu režimu, nes padidina našumą. Mažesniems gamintojams papildomas privalumas – beveik momentinis mašinos paleidimas. Esant gamybos pertraukoms, mašina nebūtinai turi būti įjungta, kaip įprastose krosnyse.

Atvėsinimas yra šiluminio apdorojimo metodas, kurio tikslas – sumažinti trapumą, trapumą, kietumą iki reikiamo lygio ir pašalinti grūdinimo įtempimus pliene, anksčiau grūdintame. Šis procesas vyksta palyginti žemose temperatūrose, žemesnėse nei grūdinimo temperatūra. Detalė kaitinama, tam tikrą laiką laikoma aukštesnėje temperatūroje ir tada lėtai aušinama.

Atvėsinimas, atliekamas naudojant indukcines sistemas, suteikia daug privalumų, aprašytų grūdinimo procese, tokių kaip trumpesnis proceso laikas (net iki kelių sekundžių!), energijos taupymas, tikslus kontrolė ir pakartojamumas. Tokios sistemų integracija gamybos linijose leidžia supaprastinti proceso valdymą, paspartinti gamybą ir padidinti pelną.

Jūsų atsiliepimo įvertinimas negali būti išsiųstas

Pranešti apie komentarą

Pranešimas apie atsiliepimą išsiųstas

Jūsų pranešimas apie atsiliepimą neišsiųstas

Parašyti savo atsiliepimą

Atsiliepimas išsiųstas

Jūsų atsiliepimas neišsiųstas