Jūs turite būti prisijungę

-

sugrįžtiX

-

Komponentai

-

-

Category

-

Puslaidininkiai

- Diodai

- Tiristoriai

-

Elektroizoliuoti moduliai

- Elektrai izoliuoti moduliai | VISHAY (IR)

- Elektrai izoliuoti moduliai | INFINEON (EUPEC)

- Elektrai izoliuoti moduliai | Semikronas

- Elektrai izoliuoti moduliai | POWEREX

- Elektrai izoliuoti moduliai | IXYS

- Elektrai izoliuoti moduliai | POSEICO

- Elektrai izoliuoti moduliai | ABB

- Elektrai izoliuoti moduliai | TECHSEM

- Eikite į subkategoriją

- Lygintuviniai tilteliai

-

Tranzistoriai

- Tranzistoriai | GeneSiC

- SiC MOSFET moduliai | Mitsubishi

- SiC MOSFET moduliai | STARPOWER

- „ABB SiC MOSFET“ moduliai

- IGBT moduliai | MITSUBISHI

- Tranzistorių moduliai | MITSUBISHI

- MOSFET moduliai | MITSUBISHI

- Tranzistorių moduliai | ABB

- IGBT moduliai POWEREX

- IGBT moduliai INFINEON (EUPEC)

- Silicio karbido puslaidininkiniai elementai

- Eikite į subkategoriją

- Valdikliai

- Galios blokai

- Eikite į subkategoriją

- Elektrinių dydžių keitikliai

-

Pasyvūs komponentai (kondensatoriai, rezistoriai, saugikliai, filtrai)

- Rezistoriai

-

Saugikliai

- ABC ir AGC serijos miniatiūriniai saugikliai elektronikai

- Greitaeigiai cilindriniai saugikliai

- Uždelsimo elementai su GL/GG ir AM charakteristikomis

- Ultragreiti intarpai - saugikliai

- Didžiosios Britanijos ir JAV standartų greitaeigiai saugikliai

- Europos standarto greitaeigiai saugikliai

- Saugikliai geležinkeliui

- Aukštos įtampos saugikliai

- Eikite į subkategoriją

-

Kondensatoriai

- Kondensatoriai varikliams

- Elektrolitiniai kondensatoriai

- Snubbers tipo kondensatoriai

- Galios kondensatoriai

- Kondensatoriai DC grandinėms

- Kondensatoriai galios kompensavimui

- Aukštos įtampos kondensatoriai

- Kondensatoriai indukciniam kaitinimui

- Impulsiniai ir energijos kaupimo kondensatoriai

- DC LINK kondensatoriai

- AC / DC grandinių kondensatoriai

- Eikite į subkategoriją

- Slopinimo tinklo filtrai

- Superkondensatoriai

- Apsauga nuo viršįtampių

- Eikite į subkategoriją

-

Relės ir kontaktoriai

- Relių ir kontaktorių teorija

- Trijų fazių puslaidininkinės AC relės

- Puslaidininkinės DC relės

- Reguliatoriai, valdikliai ir jų priedai

- Soft starteriai (minkšto paleidimo įrenginiai) bei reversiniai kontaktoriai

- Elektromechaninės relės

- Kontaktoriai

- Rotaciniai jungikliai

-

Vienos fazės puslaidininkinės AC relės

- AC vienfazės puslaidininkinės relės 1 | D2425 | D2450 serijų

- AC vienfazės puslaidininkinės relės CWA ir CWD serijų

- AC vienfazės puslaidininkinės relės CMRA ir CMRD serijų

- AC vienfazės puslaidininkinės relės PS serijos

- AC puslaidininkinės dvigubos ir keturgubos relės D24 D, TD24 Q, H12D48 D serijų

- Vienfazės puslaidininkinės relės gn serijos

- AC vienfazės puslaidininkinės relės CKR serijos

- AC vienfazės relės DIN bėgiams ERDA ir ERAA serijų

- Vienfazės kintamosios srovės relės, skirtos 150A srovei

- Dvigubos kietojo kūno relės, integruotos su radiatoriumi DIN bėgiui

- Eikite į subkategoriją

- Vienos fazės puslaidininkinės AC relės spausdinimo plokštėms

- Interfejsų relės

- Eikite į subkategoriją

- Indukciniai elementai

- Radiatoriai, varistoriai, termo apsauga

- Ventiliatoriai

- Kondicioneriai, elektros spintų aksesuarai, aušintuvai

-

Baterijos, įkrovikliai, buferiniai maitinimo šaltiniai ir keitikliai

- Baterijos, įkrovikliai - teorinis aprašymas

- Ličio jonų baterijos. Individualios baterijos. Baterijų valdymo sistema (BMS)

-

Akumuliatoriai

- Panasonic įmonės akumuliatoriai

- SSB įmonės akumuliatoriai

- Sonnenschein Dryfit įmonės akumuliatoriai

- MK Battery įmonės geliniai akumuliatoriai

- FIAMM įmonės akumuliatoriai

- Victron Energy akumuliatoriai

- „Victron Energy LiFePO4“ akumuliatoriai

- „Dyno“ baterijos

- APC UPS RBC akumuliatorių paketai

- Eikite į subkategoriją

- Akumuliatorių įkrovikliai ir priedai

- UPS atsarginis maitinimo šaltinis ir buferiniai maitinimo šaltiniai

- Fotoelektros keitikliai ir priedai

- Energijos kaupimas

- Kuro elementai

- Ląstelės litio-joninės

- Eikite į subkategoriją

-

Automatikos komponentai

- Futaba Drone Parts

- Galiniai jungikliai, mikrojungikliai

- Jutikliai, keitikliai

- Pirometrai

- Skaitikliai, laiko relės, paneliniai matuokliai

- Pramoniniai apsaugos įrenginiai

- Šviesos ir garso signalizacija

- Terminio vaizdo kamera

- LED švieslentės

- Valdymo aparatūra - mygtukai ir jungikliai

-

Registravimo prietaisai

- AL3000 - įrašantis į juostą temperatūros registratorius su skaitmeniniu ekranu

- Mikroprocesoriniai registratoriai su LCD ekranu KR2000 serijos

- Registratorius KR5000

- Matuoklis su drėgmės ir temperatūros įrašymo funkcija HN-CH

- Registratorių reikmenys

- Grafinis kompaktinis registratorius 71VR1

- Registratorius KR 3000

- PC registratoriai R1M serijos

- PC registratoriai R2M serijos

- PC registratorius, 12 izoliuotų įėjimų – RZMS

- PC registratorius, USB, 12 izoliuotų įėjimų – RZUS

- Eikite į subkategoriją

- Eikite į subkategoriją

-

Laidai, pynės, laidų apsauginės žarnos, lankstūs sujungimai

- Laidai

- Daugiagisliai laidai

-

Kabeliai ekstremalioms sąlygoms

- Kompensaciniai ir prailginimo kabeliai

- Laidai termoporoms

- PT jutikliams prijungimo laidai

- Daugiagysliai laidai temp. -60C iki +1400C

- Vidutinės įtampos kabeliai

- Uždegimo laidai

- Šildymo laidai

- Viengysliai laidai temp. -60C iki +450C

- Geležinkelio kabeliai

- Šildymo kabeliai Ex zonoms

- Eikite į subkategoriją

- Apsaugos vamzdeliai

-

Pintinės

- Plokščios pintinės

- Apvalios pintinės

- Plokščios labai elastingos pintinės

- Apvalios labai elastingos pintinės

- Cilindro formos vario pintinės

- Vario cilindrinės pintinės su apsauga

- Elastingos įžeminimo juostos

- Cinkuoto ir nerūdijančio plieno cilindrinės pintinės

- PCV izoliuotos vario pintinės - temperatūra iki 85 C

- Plokščios aliuminio pintinės

- Sujungimo komplektas - pintinės ir vamzdeliai

- Eikite į subkategoriją

- Aksesuarai geležinkeliams

- Kabelių antgaliai

- Lanksčios izoliuotos šynos

- Daugiasluoksnės lanksčios šynos

- Laidų pravedimo sistemos (PESZLE)

- Gofruotos apsauginės žarnos

- Eikite į subkategoriją

- Žiūrėti visas kategorijas

-

Puslaidininkiai

-

-

- Tiekėjai

-

Pritaikymų sąrašas

- CNC staklės

- Energetika

- Energy bank

- Indukcinis kaitinimas

- Įranga ir komponentai sprogimo pavojaus zonoms (Ex)

- Kasyklos, metalurgijos ir liejimo pramonė

- Laboratoriniai ir moksliniai matavimai

- Maitinimo šaltiniai (UPS) ir lygintuvinės sistemos

- Medienos džiovinimo ir apdirbimo mašinos

- Nuolatinės ir kintamos srovės pavaros (keitikliai)

- Paskirstymo, valdymo ir telekomunikacijos spintų įranga

- Plastmasių liejimo mašinos

- Poligrafija

- Pramoninė apsaugos įranga

- Pramoninė automatika

- Suvirinimo aparatai

- ŠVOK automatika

- Temperatūros matavimas ir nustatymas

- Tramvajų ir traukinių pavaros

- Varikliai ir transformatoriai

-

Montavimas

-

-

Induktoriai

-

-

Indukciniai įtaisai

-

-

https://www.dacpol.eu/pl/naprawy-i-modernizacje

-

-

Aptarnavimas

-

- Kontaktai

- Zobacz wszystkie kategorie

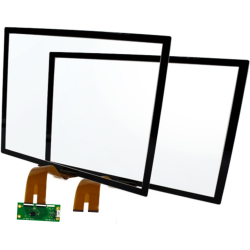

Environmental resistance of capacitive touch panels: Key features for industrial applications

In industry, the reliability and durability of devices are crucial, especially in challenging environmental conditions. In many sectors, such as manufacturing, logistics, energy, or heavy industry, technologies must withstand various challenges – from extreme temperatures and high humidity to dust and chemical exposure. In this context, capacitive touch screens stand out due to advanced technology and appropriate design, enabling their use in demanding environments.

Capacitive Screens and Environmental Conditions – What Makes Them So Resilient?

Capacitive touch panels, also known as PCAP (Projected Capacitive) screens, are often used in industrial devices and automation. A key aspect of capacitive touch screens is their electrostatic field-based operation, allowing for precise touch detection. Unlike resistive technology, capacitive screens do not require pressure – they respond to a gentle touch, making them convenient and intuitive.

Below are the main features of capacitive touch panels that make them resistant to harsh industrial conditions:

- Resistance to Extreme Temperatures

Capacitive touch panels are designed to operate across a wide temperature range, making them suitable for environments with fluctuating temperatures. In industrial applications, such as automation or control systems, capacitive touch screens must be able to function in both low and high temperatures without losing touch precision or response speed.

- Protection Against Moisture and Water

Thanks to their advanced design and the use of special protective coatings, capacitive touch screens are resistant to moisture and occasional water splashes. In industries such as food, pharmaceuticals, or logistics, capacitive screens allow stable operation even in high-humidity environments. However, it’s important to note that a capacitive screen must be adapted to its environment – in areas with frequent water exposure, it’s worth investing in models with hydrophobic coatings that further increase moisture resistance.

- Resistance to Contaminants and Dust

High levels of dust are common in industry and can damage delicate technological components. Capacitive touch screens are equipped with a glass surface, providing increased resistance to mechanical factors like dust, dirt, or metal shavings. Furthermore, the glass finish protects capacitive touch panels from scratches and mechanical damage, allowing for long-term use in harsh industrial conditions.

- Protection Against Chemicals and Harmful Substances

Capacitive touch panels are often designed for contact with chemicals that may be present in industrial environments. In chemical, pharmaceutical, or medical device manufacturing industries, capacitive screens must resist chemicals such as solvents, oils, or acids. This feature allows capacitive screens to be used in applications requiring regular contact with aggressive substances, making them a versatile solution for industry.

- Durability and Low Maintenance Requirements

The capacitive touch screen is characterized by higher durability and requires less frequent maintenance, reducing operational costs in industrial companies. The long lifespan of the capacitive touch panel makes it an excellent choice for companies seeking technology with high reliability and low operating costs.

Application of Capacitive Touch Screens in Various Industrial Sectors

Capacitive touch panels are widely used across many industrial sectors due to their environmental resistance and ease of use. Here are some examples of industries where a capacitive touch screen can be a significant value-add:

- Food and Pharmaceutical Industries – In these sectors, where cleanliness and hygiene are paramount, capacitive touch screens allow for convenient operation with minimal contamination risk. Thanks to their moisture resistance and ease of cleaning, capacitive screens are ideal for applications requiring frequent disinfection.

- Automation and Process Control – In industrial applications where devices must operate continuously, capacitive touch screens provide stable performance even in challenging conditions. In industrial automation systems, capacitive touch screens enable precise control and monitoring of production processes in real-time.

- Transport and Logistics – In the logistics and transportation industries, capacitive screens are used in interactive management and monitoring systems. With resistance to shocks, vibrations, and various weather conditions, capacitive touch panels perform excellently in vehicles and warehouses, where exposure to harsh environmental conditions is frequent.

- Heavy Industry and Energy – In heavy industry, where devices are subjected to intense use, capacitive touch panels offer high durability and resistance to mechanical factors. Dust resistance, tolerance for various temperatures, and durability make capacitive touch screens ideal for applications in power plants, factories, or mines.

What Capacitive Touch Screen Features Affect Their Durability?

In industry, technology must not only function but also perform reliably regardless of the work environment. Therefore, capacitive touch panels are often equipped with additional features that increase their resistance to industrial challenges:

- Anti-Glare Layer – Capacitive touch screens can come with an anti-glare coating, improving screen visibility in brightly lit areas or outdoors.

- Adaptability to Gloves – In industrial environments where gloves are mandatory, capacitive screens can be designed to respond to touch even when gloves are worn.

- Impact Resistance – The glass layers of capacitive touch panels are often toughened or reinforced to withstand accidental impacts or scratches.

Summary

Choosing a touch screen for industrial applications is crucial for ensuring reliability and operational efficiency. Capacitive screens offer a broad range of possibilities, combining durability with intuitive operation. Their resistance to moisture, dust, chemicals, and extreme temperatures makes them an ideal solution for industry. Regardless of environmental conditions, a capacitive touch screen ensures operational stability, minimizing downtime and maintenance costs, making it a valuable choice for many businesses.

Related products

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment