Jūs turite būti prisijungę

Category

Nuotraukos yra skirtos tik informaciniams tikslams. Peržiūrėkite produkto specifikaciją

please use latin characters

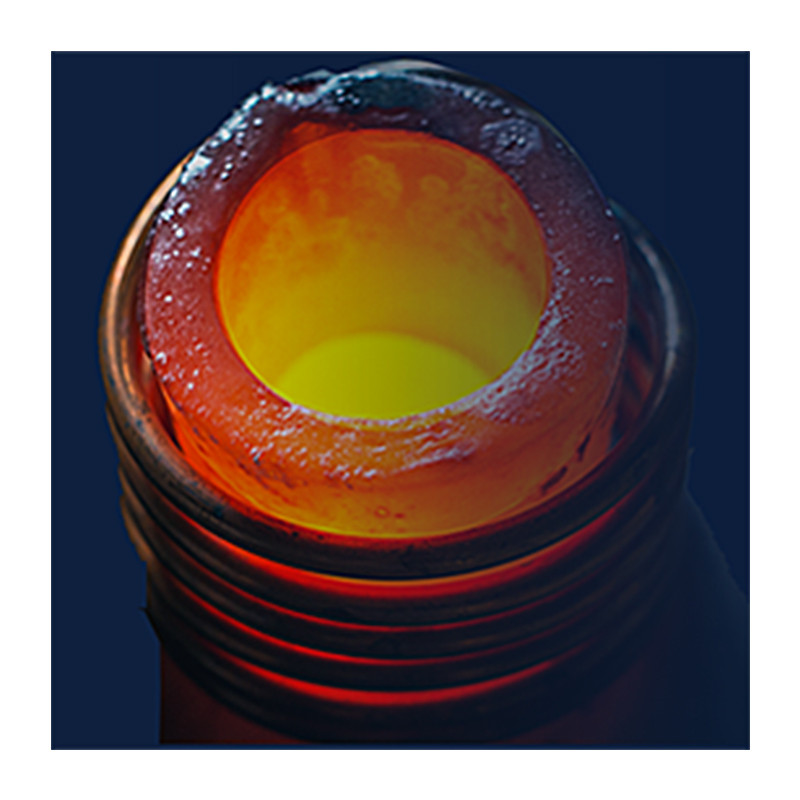

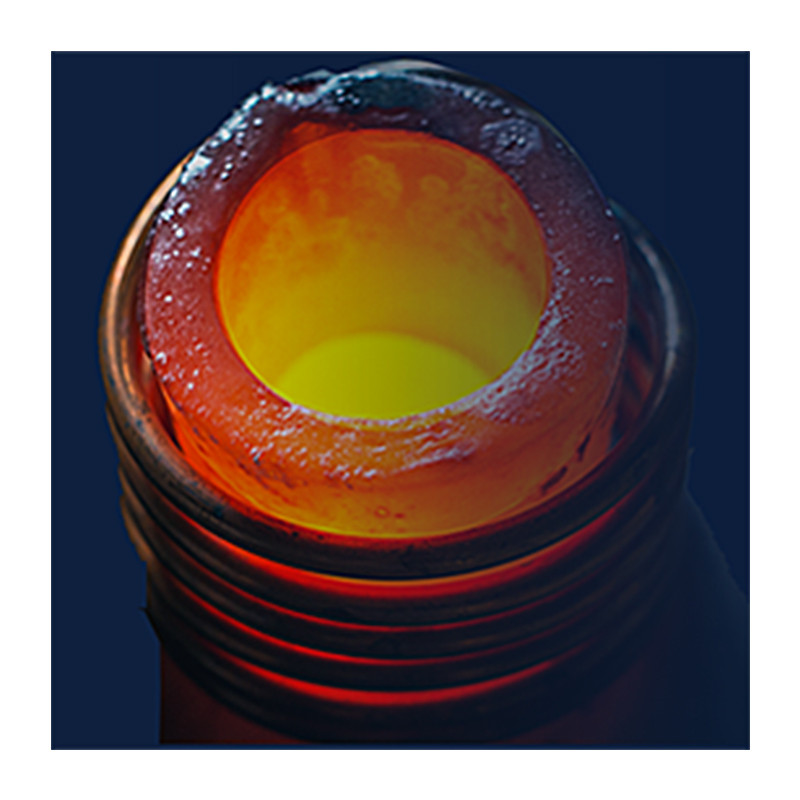

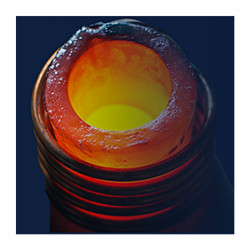

Melting metals with solid state RF induction heating is usually accomplished by heating the metal in a crucible made from a non-conductive refractory material. The charge of metal within the crucible is melted down to liquid form.

This process is commonly used to produce high quality steels and nonferrous alloys for casting operations. The liquified metal is poured into a cavity having the desired shape. The metal solidifies with a minimum of shrinkage, after which the mold is removed to reveal a finished, machinable product

Modern induction heating provides reliable, repeatable, non-contact and energy-efficient heat in a minimal amount of time. Induction produces circular eddy currents within the molten mass, creating a stirring action which results in a very uniform product. Induction heating provides fast, controllable temperature ramp, allowing for consistent quality results. Both ferrous and non-ferrous alloys can be melted in induction furnaces. The flexibility and cleanliness of induction melting cannot be duplicated by conventional steel mill and foundry methods.

Typical induction furnaces for melting range from 1 to 20kW, depending on the metal and application requirements

Ar Jūs domina šis produktas? Ar Jums reikia papildomos informacijos ar individualaus pasiūlymo?

tu turi būti prisijungęs

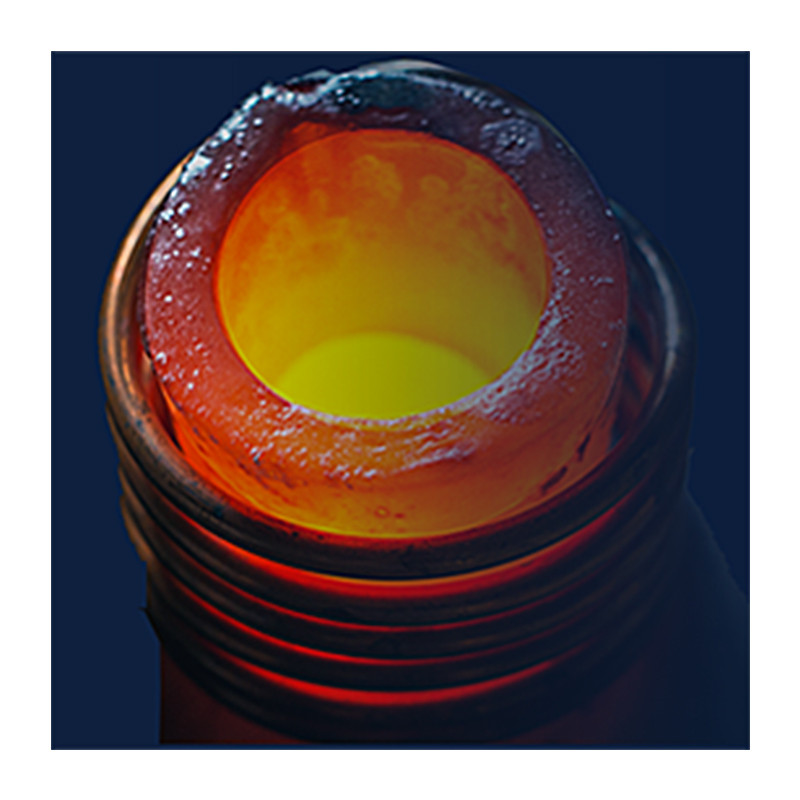

Melting metals with solid state RF induction heating is usually accomplished by heating the metal in a crucible made from a non-conductive refractory material. The charge of metal within the crucible is melted down to liquid form.

This process is commonly used to produce high quality steels and nonferrous alloys for casting operations. The liquified metal is poured into a cavity having the desired shape. The metal solidifies with a minimum of shrinkage, after which the mold is removed to reveal a finished, machinable product

Modern induction heating provides reliable, repeatable, non-contact and energy-efficient heat in a minimal amount of time. Induction produces circular eddy currents within the molten mass, creating a stirring action which results in a very uniform product. Induction heating provides fast, controllable temperature ramp, allowing for consistent quality results. Both ferrous and non-ferrous alloys can be melted in induction furnaces. The flexibility and cleanliness of induction melting cannot be duplicated by conventional steel mill and foundry methods.

Typical induction furnaces for melting range from 1 to 20kW, depending on the metal and application requirements

Jūsų atsiliepimo įvertinimas negali būti išsiųstas

Pranešti apie komentarą

Pranešimas apie atsiliepimą išsiųstas

Jūsų pranešimas apie atsiliepimą neišsiųstas

Parašyti savo atsiliepimą

Atsiliepimas išsiųstas

Jūsų atsiliepimas neišsiųstas