Jūs turite būti prisijungę

Category

Nuotraukos yra skirtos tik informaciniams tikslams. Peržiūrėkite produkto specifikaciją

please use latin characters

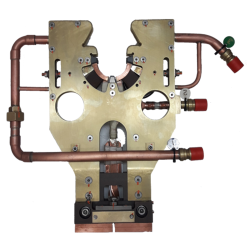

The modernization of the inductor is the introduction of changes in its design aimed at:

Example:

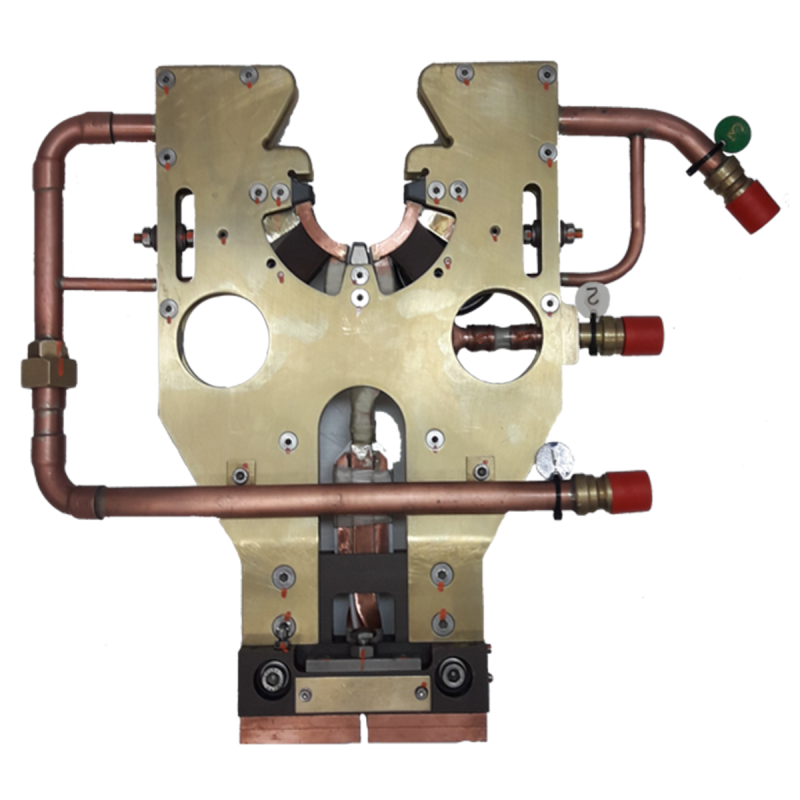

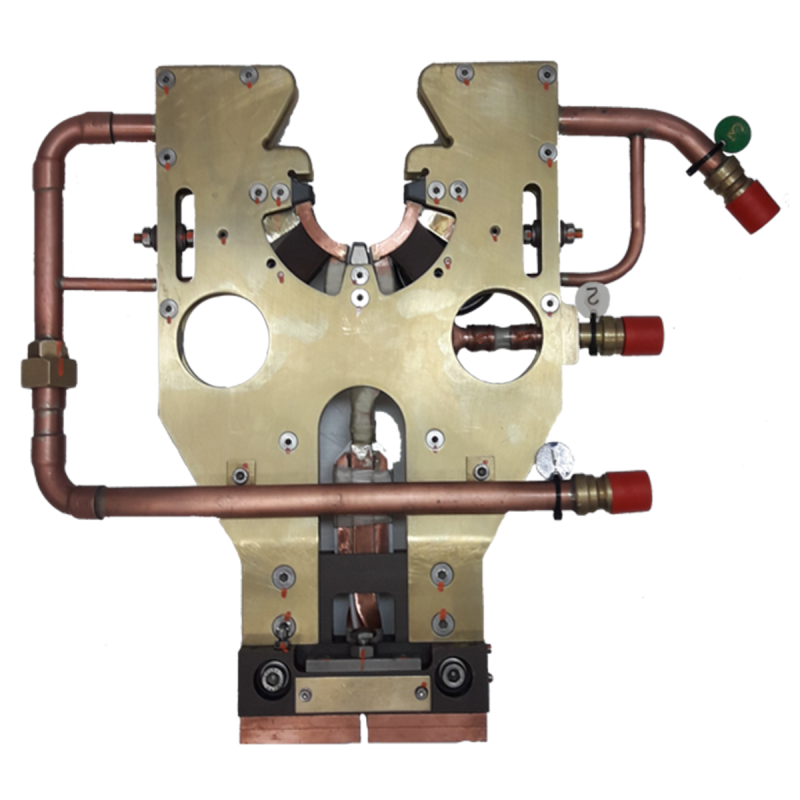

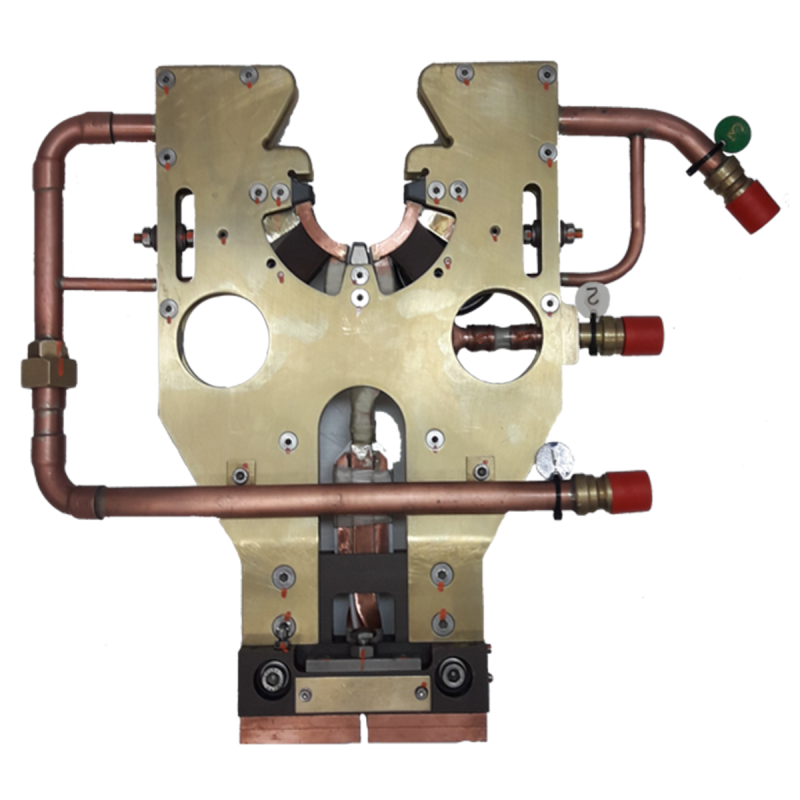

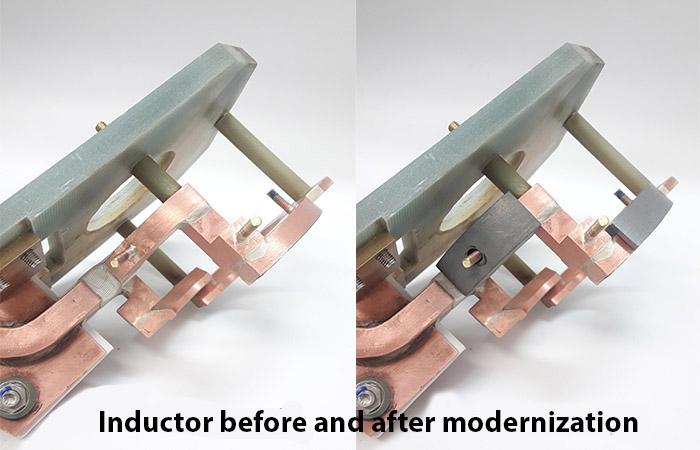

The change in the shape of the inductor head and the use of magnetic field concentrators allowed to increase the precision and reduce heating in non-hardened zones, increase the efficiency of the process by more precisely focusing energy to the hardened area, reducing the heating time while maintaining the same value of power absorbed.

Ar Jūs domina šis produktas? Ar Jums reikia papildomos informacijos ar individualaus pasiūlymo?

tu turi būti prisijungęs

The modernization of the inductor is the introduction of changes in its design aimed at:

Example:

The change in the shape of the inductor head and the use of magnetic field concentrators allowed to increase the precision and reduce heating in non-hardened zones, increase the efficiency of the process by more precisely focusing energy to the hardened area, reducing the heating time while maintaining the same value of power absorbed.

The use of induction heating in the manufacture of industrial equipment

The use of induction heating in the manufacture of industrial equipment

Jūsų atsiliepimo įvertinimas negali būti išsiųstas

Pranešti apie komentarą

Pranešimas apie atsiliepimą išsiųstas

Jūsų pranešimas apie atsiliepimą neišsiųstas

Parašyti savo atsiliepimą

Atsiliepimas išsiųstas

Jūsų atsiliepimas neišsiųstas