trebuie să fii logat

Category

Fotografiile au doar scop informativ. Vizualizați specificațiile produsului

please use latin characters

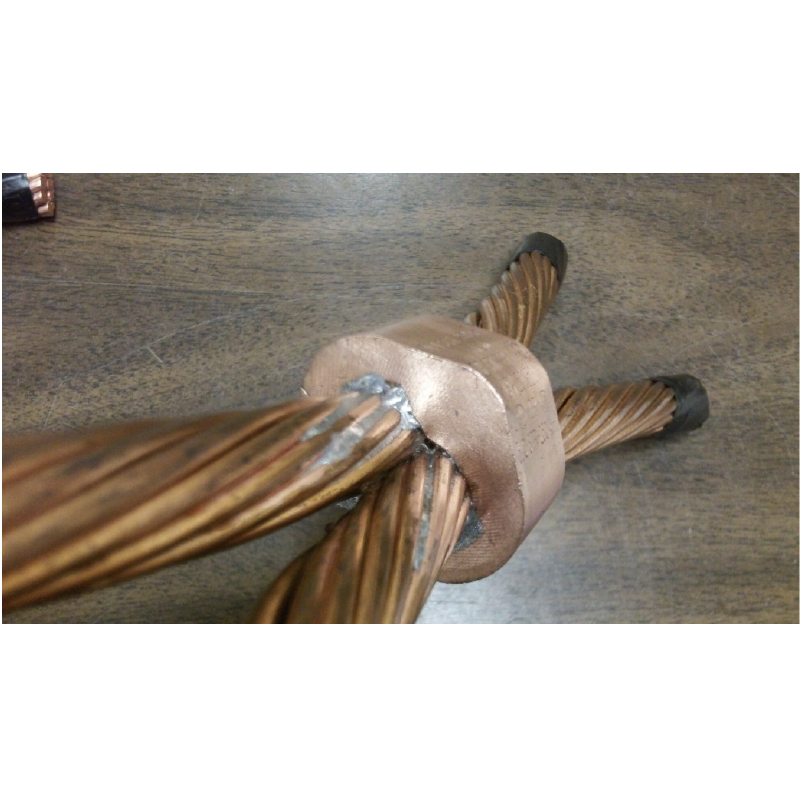

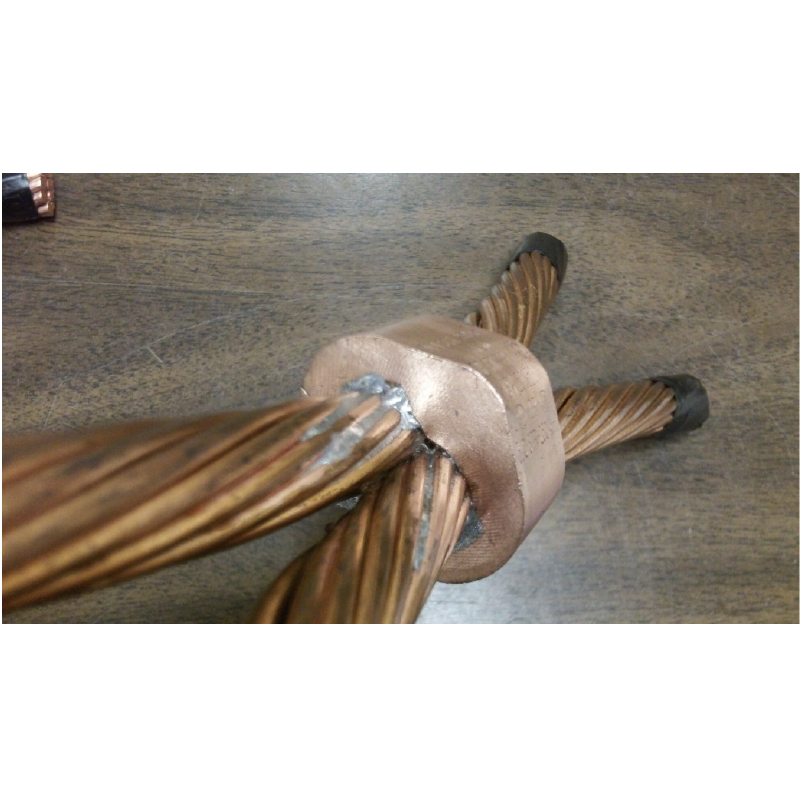

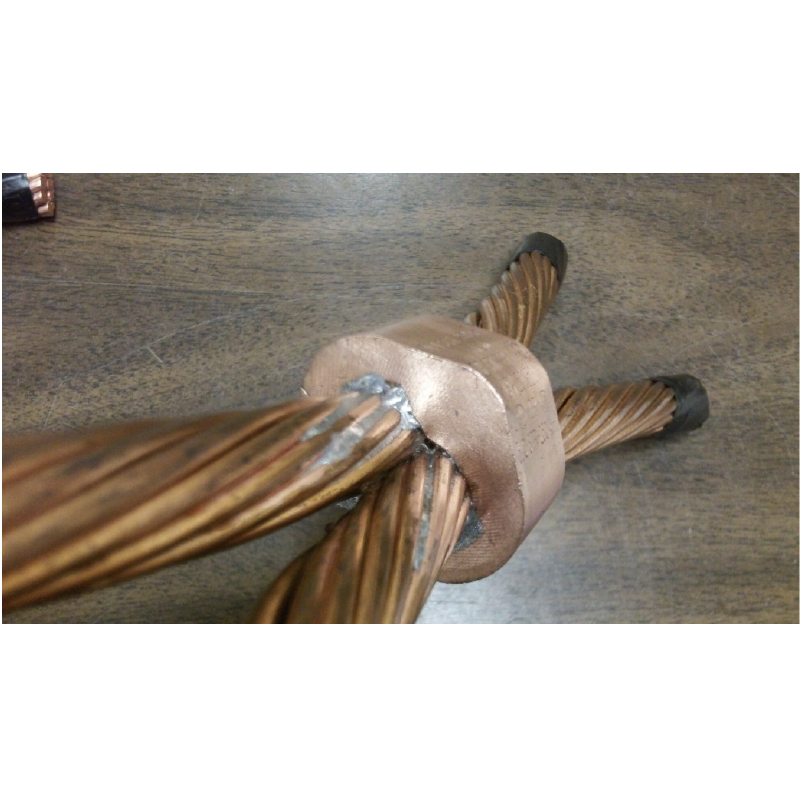

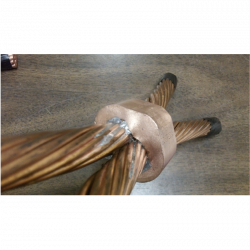

Objective: To heat a copper lug and a wire to temperature for a soldering application to create grounding connections.

Frequency: 109 kHz

Material: Wire and lug

Temperature: 370 °F (188 °C)

The parts were fluxed and the solder wire was folded two times and twisted to enable a greater feed rate. The assembly was then placed in the coil and the power was turned on. The coil was designed to focus heat on the large lug and to keep solder from running over the wires. After 40 seconds, the assembly reached soldering temperature.

It was observed that the lug could easily be filled with solder when it’s placed in a vertical direction and the solder will run out of the bottom when full. If the lug was oriented in a horizontal position the solder could be more readily kept in and around the lug.

Sunteți interesat de acest produs? Aveți nevoie de informații suplimentare sau de prețuri individuale?

trebuie să fii logat

Objective: To heat a copper lug and a wire to temperature for a soldering application to create grounding connections.

Frequency: 109 kHz

Material: Wire and lug

Temperature: 370 °F (188 °C)

The parts were fluxed and the solder wire was folded two times and twisted to enable a greater feed rate. The assembly was then placed in the coil and the power was turned on. The coil was designed to focus heat on the large lug and to keep solder from running over the wires. After 40 seconds, the assembly reached soldering temperature.

It was observed that the lug could easily be filled with solder when it’s placed in a vertical direction and the solder will run out of the bottom when full. If the lug was oriented in a horizontal position the solder could be more readily kept in and around the lug.

Aprecierea ta pentru recenzie nu a putut fi trimisa

Reclama un comentariu

Raport trimis

Reclamatia tau nu a putut fi trimisa

Scrie-ti recenzia

Recenzia a fost trimisa

Recenzia ta nu a putut fi trimisa