trebuie să fii logat

Category

Fotografiile au doar scop informativ. Vizualizați specificațiile produsului

please use latin characters

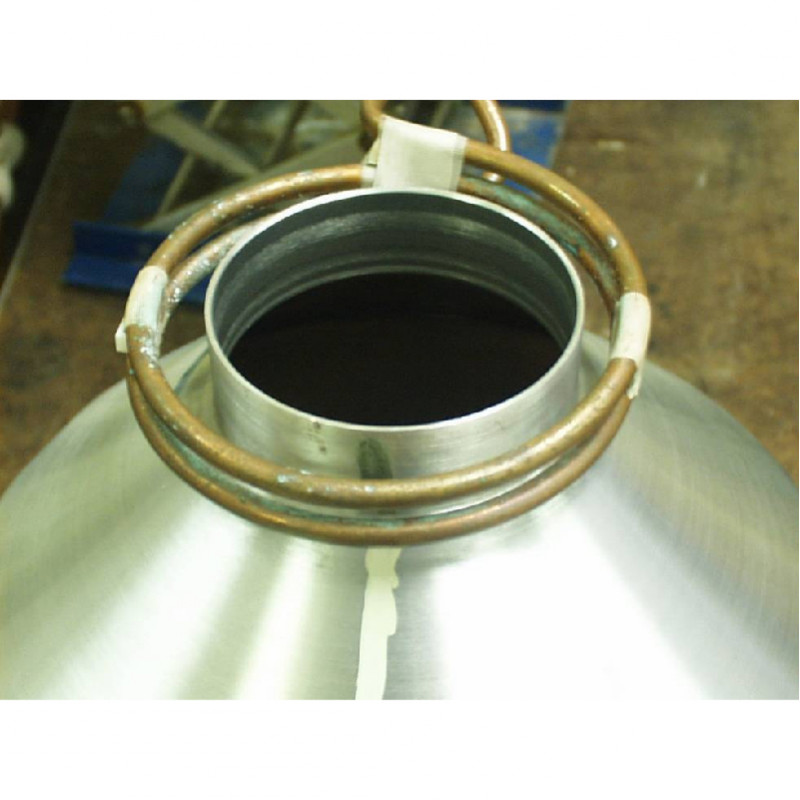

Objective: Annealing a 1” lip on aluminum cryogenic dewar* that has been work hardened during the process of spin forming.

Frequency: 303 kHz

Material: Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick.

Temperature: 800 °F (427 °C)

A two turn helical coil is used to heat the lip on the cryogenic dewar. The dewar is placed in the coil and power is applied for 2 minutes to anneal the required 1” heat zone.

Sunteți interesat de acest produs? Aveți nevoie de informații suplimentare sau de prețuri individuale?

trebuie să fii logat

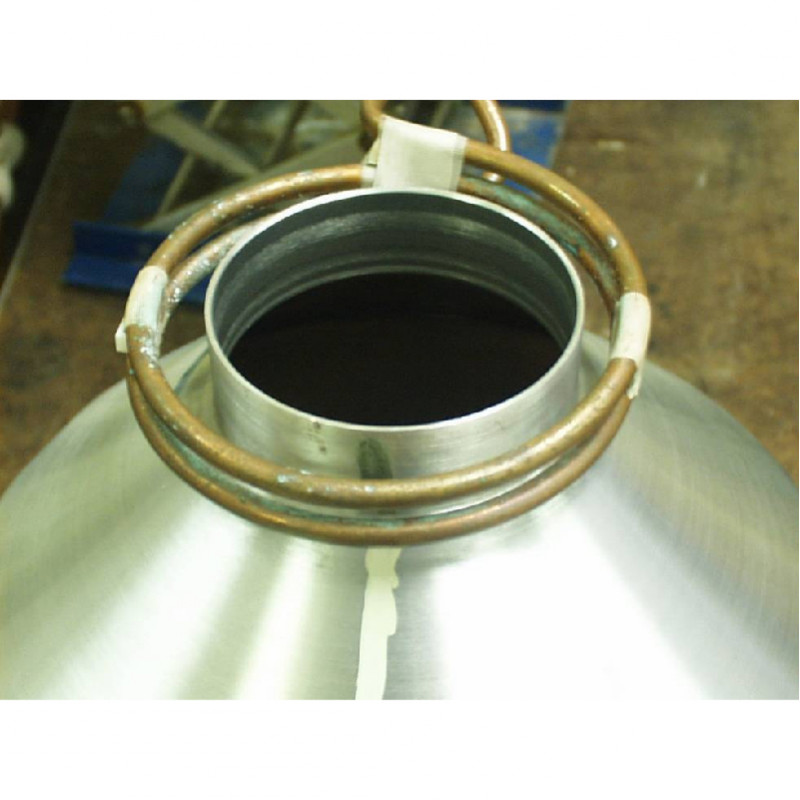

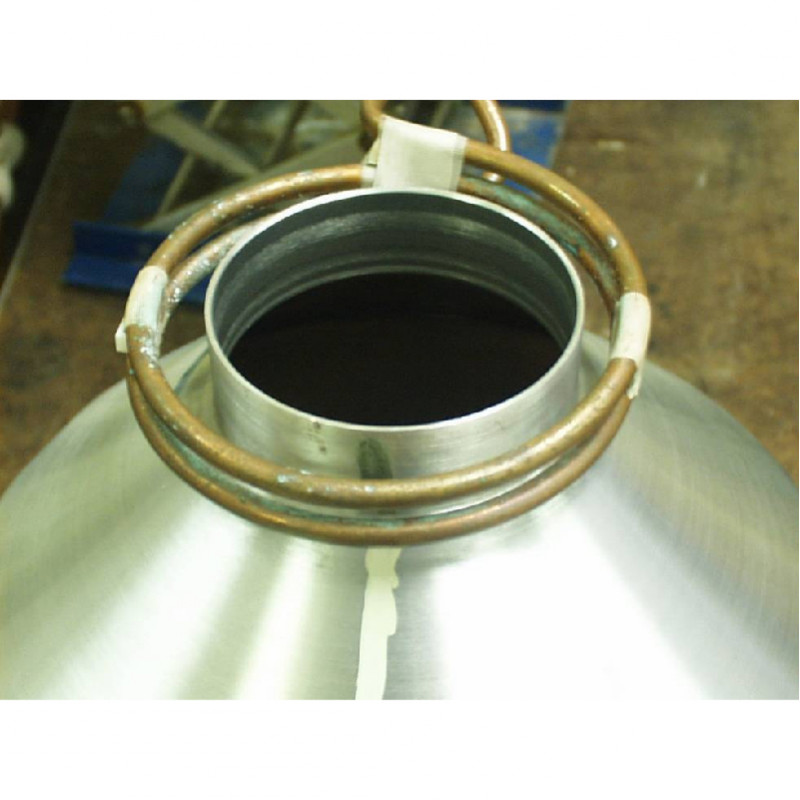

Objective: Annealing a 1” lip on aluminum cryogenic dewar* that has been work hardened during the process of spin forming.

Frequency: 303 kHz

Material: Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick.

Temperature: 800 °F (427 °C)

A two turn helical coil is used to heat the lip on the cryogenic dewar. The dewar is placed in the coil and power is applied for 2 minutes to anneal the required 1” heat zone.

Aprecierea ta pentru recenzie nu a putut fi trimisa

Reclama un comentariu

Raport trimis

Reclamatia tau nu a putut fi trimisa

Scrie-ti recenzia

Recenzia a fost trimisa

Recenzia ta nu a putut fi trimisa