trebuie să fii logat

Category

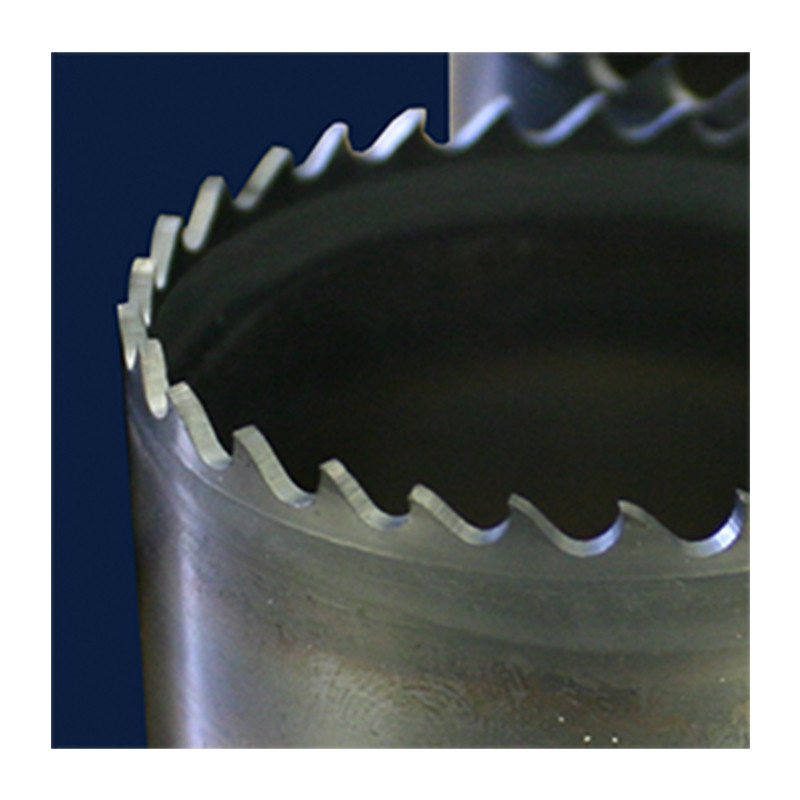

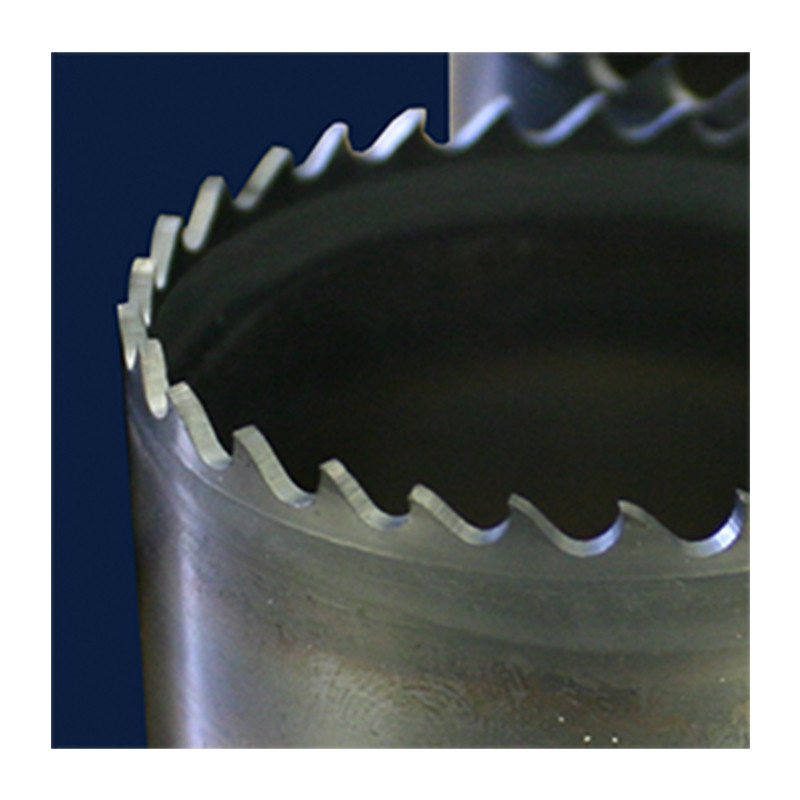

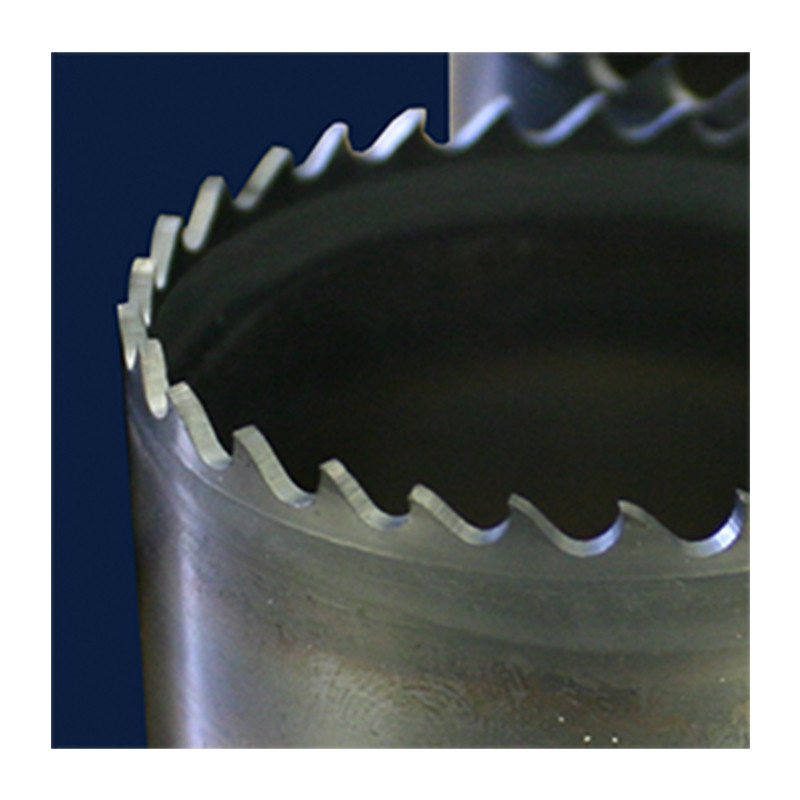

Fotografiile au doar scop informativ. Vizualizați specificațiile produsului

please use latin characters

Întărirea este un tip de tratament termic care are ca scop obținerea unei durități, rezistențe și rezistențe la uzură mai mari, cu o plasticitate redusă și o fragilitate crescută. În funcție de adâncimea întăririi, se disting întărirea volumetrică și întărirea la suprafață. Întărirea volumetrică constă în încălzirea materialului pe întreaga secțiune la temperatura dorită pentru transformări, menținerea la această temperatură și răcirea la o viteză corespunzătoare. Acest proces este utilizat pentru întărirea oțelurilor cu conținut mediu și mare de carbon, pentru a obține o rezistență și duritate moderate. Întărirea la suprafață constă în încălzirea rapidă a unei straturi subțiri de suprafață a materialului la temperatura dorită pentru transformări și răcirea rapidă. Astfel se obține o duritate și o rezistență crescute doar până la o adâncime prestabilită, cu o structură neîntărită în restul materialului. Ca agent de răcire, se folosesc de obicei: ulei, aer, apă, apă cu polimeri solubili etc.

Tehnologiile moderne de încălzire prin inducție oferă încălzire fiabilă și fără contact într-un timp minim, fără flacără. O caracteristică importantă este repetabilitatea și precizia procesului – posibilitatea de a seta timpul, temperatura, controlul adâncimii întăririi, răcirea și porțiunea piesei care urmează să fie prelucrată. Sistemele pe semiconductori pot încălzi chiar și zone foarte mici, respectând cu precizie intervalele de toleranță ale procesului de producție.

Întărirea prin inducție se efectuează în două moduri. Primul este întărirea statică, care constă în efectuarea operației de încălzire fără schimbarea poziției piesei sau a inductorei față de ele. Această metodă se caracterizează prin rapiditate, fără a necesita automatizări complexe și permite stabilirea precisă a zonei de încălzit, chiar și pentru piesele cu forme complexe. Al doilea mod este întărirea progresivă, care constă în efectuarea operației de încălzire prin schimbarea poziției piesei și a inductorei față de ele. Aceasta permite întărirea pieselor cu suprafețe și dimensiuni mari, precum și încălzirea mai multor zone specifice ale unei singure piese, fără a fi necesare ajustări manuale ale poziției.

Prelucrarea termică prin sisteme de inducție este ideală pentru aplicații în industrii care necesită un proces automatizat, precis și rapid. Încălzirea prin inducție se potrivește foarte bine pentru marii producători care au multe linii de producție cu fabricație continuă, datorită creșterii eficienței. Pentru producătorii mai mici, un alt avantaj este pornirea aproape instantanee a mașinii. În cazul întreruperilor de producție, mașina nu trebuie să rămână în permanență pornită, așa cum se întâmplă la cuptoarele tradiționale.

Revenirea este un tip de tratament termic care are ca scop reducerea fragilității, fragilității, durității până la nivelul dorit și eliminarea tensiunilor de întărire din oțelul anterior întărit. Acest proces se efectuează la temperaturi relativ scăzute, mai mici decât temperatura de întărire. Piesa este încălzită, menținută la o temperatură mai mare pentru o perioadă de timp și apoi răcită lent.

Revenirea efectuată cu sisteme de inducție aduce multe avantaje menționate și în procesul de întărire, cum ar fi timpi mai scurți ai procesului (chiar și în câteva secunde!), economii de energie, control precis și repetabilitate. Integrarea acestor sisteme în liniile de producție permite simplificarea gestionării procesului, accelerarea producției și creșterea profitului.

Sunteți interesat de acest produs? Aveți nevoie de informații suplimentare sau de prețuri individuale?

trebuie să fii logat

Întărirea este un tip de tratament termic care are ca scop obținerea unei durități, rezistențe și rezistențe la uzură mai mari, cu o plasticitate redusă și o fragilitate crescută. În funcție de adâncimea întăririi, se disting întărirea volumetrică și întărirea la suprafață. Întărirea volumetrică constă în încălzirea materialului pe întreaga secțiune la temperatura dorită pentru transformări, menținerea la această temperatură și răcirea la o viteză corespunzătoare. Acest proces este utilizat pentru întărirea oțelurilor cu conținut mediu și mare de carbon, pentru a obține o rezistență și duritate moderate. Întărirea la suprafață constă în încălzirea rapidă a unei straturi subțiri de suprafață a materialului la temperatura dorită pentru transformări și răcirea rapidă. Astfel se obține o duritate și o rezistență crescute doar până la o adâncime prestabilită, cu o structură neîntărită în restul materialului. Ca agent de răcire, se folosesc de obicei: ulei, aer, apă, apă cu polimeri solubili etc.

Tehnologiile moderne de încălzire prin inducție oferă încălzire fiabilă și fără contact într-un timp minim, fără flacără. O caracteristică importantă este repetabilitatea și precizia procesului – posibilitatea de a seta timpul, temperatura, controlul adâncimii întăririi, răcirea și porțiunea piesei care urmează să fie prelucrată. Sistemele pe semiconductori pot încălzi chiar și zone foarte mici, respectând cu precizie intervalele de toleranță ale procesului de producție.

Întărirea prin inducție se efectuează în două moduri. Primul este întărirea statică, care constă în efectuarea operației de încălzire fără schimbarea poziției piesei sau a inductorei față de ele. Această metodă se caracterizează prin rapiditate, fără a necesita automatizări complexe și permite stabilirea precisă a zonei de încălzit, chiar și pentru piesele cu forme complexe. Al doilea mod este întărirea progresivă, care constă în efectuarea operației de încălzire prin schimbarea poziției piesei și a inductorei față de ele. Aceasta permite întărirea pieselor cu suprafețe și dimensiuni mari, precum și încălzirea mai multor zone specifice ale unei singure piese, fără a fi necesare ajustări manuale ale poziției.

Prelucrarea termică prin sisteme de inducție este ideală pentru aplicații în industrii care necesită un proces automatizat, precis și rapid. Încălzirea prin inducție se potrivește foarte bine pentru marii producători care au multe linii de producție cu fabricație continuă, datorită creșterii eficienței. Pentru producătorii mai mici, un alt avantaj este pornirea aproape instantanee a mașinii. În cazul întreruperilor de producție, mașina nu trebuie să rămână în permanență pornită, așa cum se întâmplă la cuptoarele tradiționale.

Revenirea este un tip de tratament termic care are ca scop reducerea fragilității, fragilității, durității până la nivelul dorit și eliminarea tensiunilor de întărire din oțelul anterior întărit. Acest proces se efectuează la temperaturi relativ scăzute, mai mici decât temperatura de întărire. Piesa este încălzită, menținută la o temperatură mai mare pentru o perioadă de timp și apoi răcită lent.

Revenirea efectuată cu sisteme de inducție aduce multe avantaje menționate și în procesul de întărire, cum ar fi timpi mai scurți ai procesului (chiar și în câteva secunde!), economii de energie, control precis și repetabilitate. Integrarea acestor sisteme în liniile de producție permite simplificarea gestionării procesului, accelerarea producției și creșterea profitului.

Aprecierea ta pentru recenzie nu a putut fi trimisa

Reclama un comentariu

Raport trimis

Reclamatia tau nu a putut fi trimisa

Scrie-ti recenzia

Recenzia a fost trimisa

Recenzia ta nu a putut fi trimisa