trebuie să fii logat

Category

Fotografiile au doar scop informativ. Vizualizați specificațiile produsului

please use latin characters

|

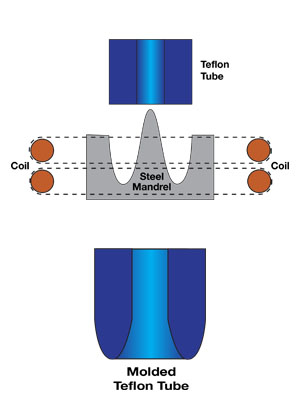

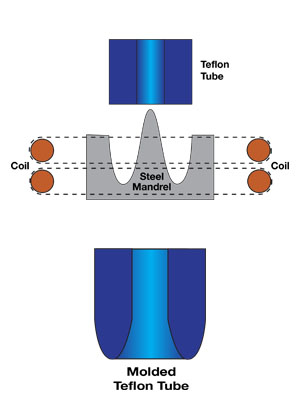

Objective: Heat a water-cooled steel mandrel to 700°F (371ºC) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700°F (315.6-371ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660ºF (371.1ºC) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Sunteți interesat de acest produs? Aveți nevoie de informații suplimentare sau de prețuri individuale?

trebuie să fii logat

|

Objective: Heat a water-cooled steel mandrel to 700°F (371ºC) to form a high quality Teflon catheter tip. Material: Teflon catheter tubing, mandrel assembly Temperature: 600-700°F (315.6-371ºC) Frequency: 376 kHz Equipment:

Process: A two turn coil is used to heat the steel mandrel to 660ºF (371.1ºC) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip. Benefits:

|

|

Aprecierea ta pentru recenzie nu a putut fi trimisa

Reclama un comentariu

Raport trimis

Reclamatia tau nu a putut fi trimisa

Scrie-ti recenzia

Recenzia a fost trimisa

Recenzia ta nu a putut fi trimisa