Articolul descrie celulele de combustie pe bază de hidrogen – o tehnologie care transformă hidrogenul în energie electrică în mod eficient și ecologic. Sunt prezentate principiile de funcționare ale celulelor, aplicațiile lor în industria auto, industrială și energetică, precum și avantajele, cum ar fi realimentarea rapidă, autonomia mare și posibilitatea integrării cu surse regenerabile de energie. Această tehnologie reprezintă o soluție promițătoare pentru dezvoltarea durabilă și tranziția energetică.

Componente pentru electronică de putere, automatizări, electronice, electrice.

Categorii de produse

Vizualizați toate categoriileArticole

-

Cum influențează răcirea și climatizarea dulapurilor durata de viață a componentelor electroniceRead more

Articolul discută importanța răcirii și climatizării dulapurilor de control pentru menținerea duratei de viață a componentelor electronice. Explică cum temperatura și umiditatea stabile îmbunătățesc fiabilitatea sistemelor industriale, descrie diferite metode de răcire, rolul designului dulapurilor și al amplasării componentelor și evidențiază eficiența energetică în instalațiile industriale moderne.

-

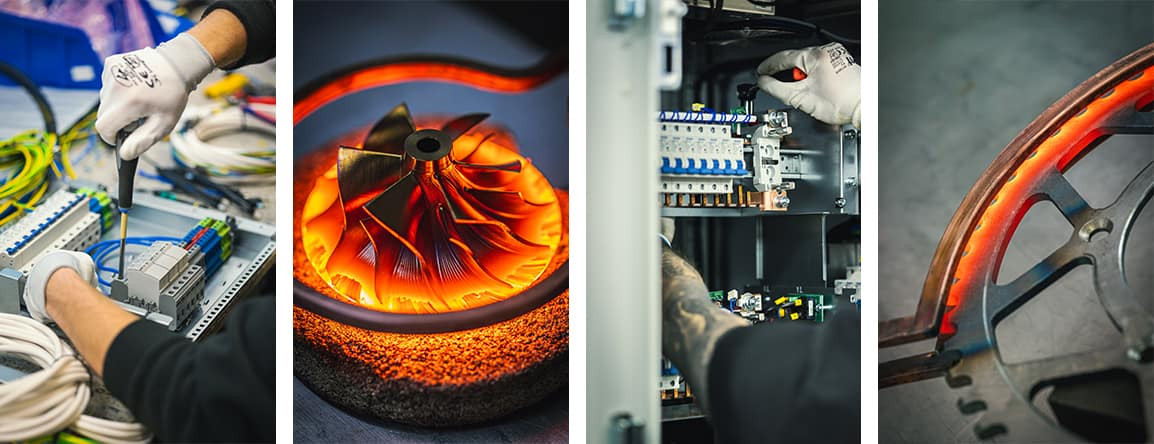

Cum schimbă echipamentele inductive procesele de producție?Read more

Articolul prezintă principiul de funcționare al încălzirii prin inducție și explică de ce această tehnologie este tot mai utilizată în industria modernă. Sunt descrise construcția și funcționarea echipamentelor inductive, principalele lor avantaje față de metodele tradiționale de încălzire, precum și o gamă largă de aplicații – de la călire și lipire până la topirea metalelor și testele de laborator. Articolul evidențiază, de asemenea, capacitățile DACPOL SERVICE și subliniază rolul companiei ca partener tehnologic în proiectarea, implementarea și service-ul sistemelor de încălzire prin inducție.